A major change has taken place in the selection of HVAC filters. The coronavirus has resulted in initiatives to use more efficient filters wherever possible. New developments in nanofibers and other media are allowing purchasers to achieve high efficiency without excessive energy consumption.

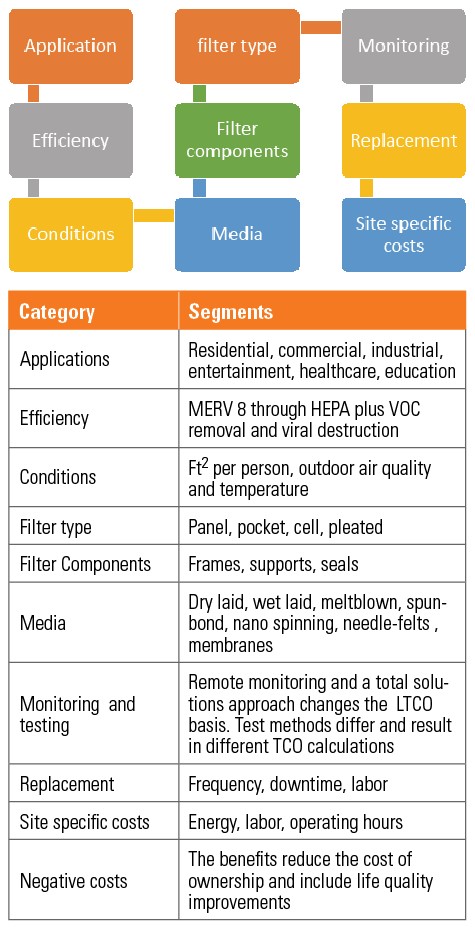

Lowest total cost of ownership factors in selecting an HVAC filter depend on a number of categories and segments.

The selection of the best filter is a challenging one given all the variables. Fortunately, there is a wealth of available data instantly available online. It can be characterized as an Industrial Internet of Wisdom (IIOW). Links to some of this relevant data available on HVAC filtration can be found at bit.ly/iiow-hvac-filtration. However, the IIOW on HVAC filters needs to be constantly revised and expanded. There needs to be greater insight on issues that are important and about which there is disagreement.

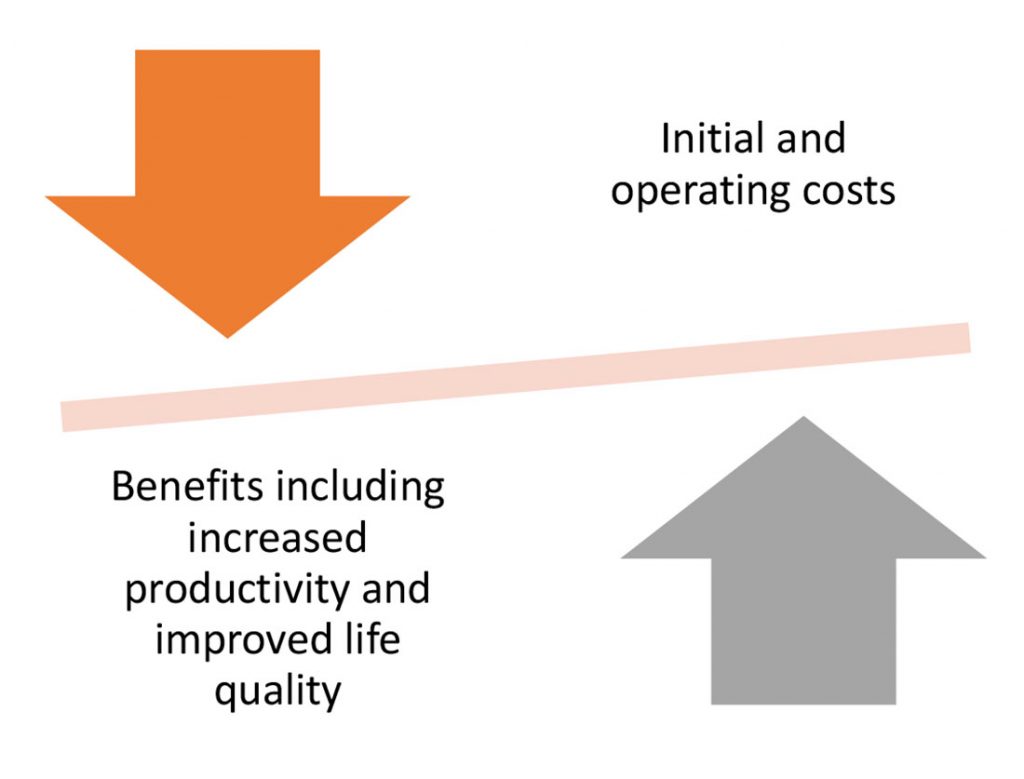

The benefits are negative costs. The lowest total cost of ownership is the solution, which provides the greatest ratio of benefits to costs. This could also be viewed as the highest return on investment (ROI).

There are articles both pro and con relative to MERV A testing. Proponents say that by loading the filter prior to testing, you duplicate operating conditions. This loading can significantly reduce electrostatic attraction and therefore filter efficiency.

The other view is that the test loading far exceeds what would be normally experienced. Furthermore, mechanical efficiency would be reduced as well with such a high load.

Mcilvaine asks why the additional loading would reduce mechanical efficiency? Dust collector experience is that the efficiency increases with loading and that just after a bag is pulsed, the emissions increase. Pressure drop would increase and removal per unit of energy consumed might be reduced, but not total removal.

When is a pre-filter required and how efficient should it be? A pre-filter will increase the life of the final filter, but this savings has to be weighed against the additional pressure drop. Is there also an efficiency implication? Does a loaded filter reduce electrostatic charging?

How big of a factor is the cost of media processing in the TCO. Filter media manufacturer Hollingsworth & Vose says, “Media processability is a major part in the cost of filter production. There is both a qualitative and quantitative aspect to media processability. Quality refers to the ease of pleating the media while producing the ‘ideal’ pleat profile. The speed at which media can be pleated with the least amount of wasted time and scrap is a quantitative factor.”

Energy cost in Nevada is half of what it is in Connecticut. In general, the energy is a bigger cost than the filters or the labor to replace filters. Is there sufficient agreement on energy costs, or should the industry participants work together to provide a table of energy cost by region and country?

Upgrading from a MERV 8 to MERV 13 filter can result in either fan upgrades or lost volume. Various filter designs and the use of pre-filters can impact the cost of ductwork and other modifications for higher efficiency. So, categorization of the designs is important.

Is there agreement on the filter categories of panel, pleated, pocket and rigid cell? What causes a specific filter design to provide lower total cost of ownership?

Leakage between the media and the support structure is cited as a potential problem. Is this common?

There are new test methods which compare the relative efficiency of different filters not just on one pass through the filter but on multiple passes. This simulates the actual use. How would a lower efficiency filter compare in total capture over time?

A related question is the volume of air being recirculated and the filter efficiency versus ambient air quality. Would a lower efficiency filter but higher recirculating rate result in increased air quality?

This question is further complicated by the need to keep CO₂ levels low and to eliminate certain gaseous contaminants. Carbon and other adsorbents may be necessary for VOC removal. Dilution with outside air is needed to minimize CO₂ accumulation.

The greater perceived benefits are changing the negative costs. Now the lowest total cost of ownership is typically a MERV 13 or higher efficiency filter. Since most installed filters are MERV 8 or lower, this changed perception is a major factor in determining the LTCO.

There has been extensive discussion of the WELL health-safety seal for buildings, a certification for facilities that meet certain criteria for a healthy indoor environment, which includes benchmarks for indoor air quality. Hollywood celebrities are reaching tens of million people each week with a message on the benefits of clean air in buildings.

Sickness, comfort, and mental health are just some of the talking points. The scientific support for these claims is less important to a building owner than the perceived benefits. People will favor stores and restaurants based on these perceived benefits.

There are likely to be continuing product, regulatory and social developments relative to HVAC filters. Suppliers and purchasers need to increasingly utilize and contribute to the IIOW to enable lowest total cost of ownership decisions.