Dutch membrane specialist NX Filtration produces advanced hollow-fiber membrane modules for nanofiltration, ultrafiltration and microfiltration applications. Its direct nanofiltration (dNF) concept was designed to remove micropollutants, color, nanoplastics, selective salts and pharmaceuticals from water in one single step: without pre-treatment and without the use of chemicals. Together with a production method based on green chemistry and significant energy savings during operation, this provides a unique and sustainable solution.

As an independent membrane supplier NX Filtration actively supports its OEM customers and distributors with readily available pilots, an advanced projection tool, and on-site installation support. NX Filtration is purely focused on the development and production of hollow-fiber membrane technology while supporting its customers in the application of this relatively new technology.

Technology benefits

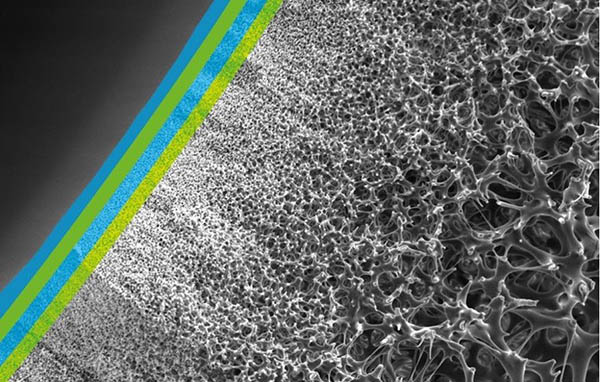

NX Filtration’s inside-out hollow fiber membranes are based on unique recipes and innovative patented production methods. The base material for NX membranes is PolyEtherSulfone (PES), which has thermal stability advantages and enables small pore sizes in nanometer scale and narrow pore size distribution. The membranes are manufactured with a patented layer-by-layer process, where multiple nano-scale layers are deposited on a membrane support. This method enables very precise and controlled rejection and flux properties of the membrane. A unique solution for troubled water.

NX Filtration’s dNF membranes are capable of retaining micropollutants such as medicine residues, pharmaceuticals, PFAS, bacteria, viruses, microplastics, from raw water in one step, without any pretreatment other than a strainer.

The fouling-resistant hollow-fiber configuration supports several different chemical free methods to keep the membrane clean, such as backwash, forward flush or air draining, and variable hydrodynamics via adjustment of the crossflow velocities. Because these membranes don’t need pre-treatment other than a strainer they were named “direct nanofiltration,” or dNF.

Spiral-wound membranes are a good product, especially for RO. These membranes have high rejection and good permeability. However, they need spacers, which are always the starting point for biofouling or scaling on the membrane. And therefore, they typically require a pre-treatment setup with, for example, ultrafiltration membranes. The dNF membranes eliminate the need for such a pre-treatment step.

The chemistry for dNF is built on water-based polyelectrolytes to make very stable, cross-linked complexes, and it is chlorine-resistant. Thin film composite membranes with polyamide layers are not.

NX Filtration’s dNF membranes come in two variants and are typically developed for the removal of micropollutants or, more generally, low molecular weight organics, such as medicine residues, hormones, PFAS, pharmaceuticals, nano-plastics and pesticides. The dNF80 variant focusses on micropollutant removal, whereas the denser dNF40 variant also retains hardness. Because the membranes typically do not retain monovalent salts, they can be operated in a low-pressure regime, thus saving energy, and eliminating remineralization.

Core applications

In principle, the dNF membranes can replace any traditional UF-SWNF of UF-RO membrane train, but they also open up entirely new applications. And the modular setup allows for both very large centralized systems to small, decentralized water treatment systems.

In the industrial markets, dNF is applied both for the sustainability benefits and water footprint reduction, but also for the saving of discharge costs, and even for the recovery of valuable raw materials, and of course water. The technology is not only efficient for process water production from well water or surface water, but also in the rapidly developing wastewater reuse segment.

In the municipal markets, dNF is already applied for municipal direct drinking water production and municipal wastewater treatment for reuse. Today an array of municipalities are actively piloting with dNF to get an understanding of the separation characteristics.