As we embark upon the journey of the new age of filtration, Park Nonwoven is relentlessly working on research and development for new generation filter media to cater to the critical issues of the industry and leveraging on the emerging opportunities with a newer world view.

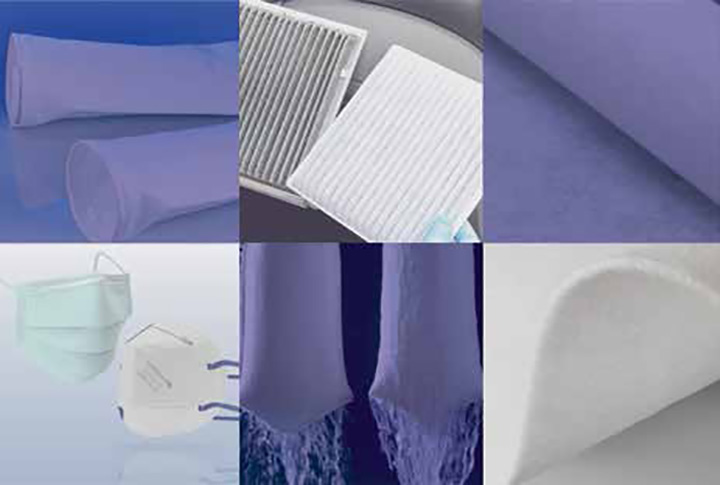

Nonwovens have become a significant part of many industries, owing to their widespread use in mitigating the purification challenges of the world, many industries, and governments at large. Moreover, as sustainable development and technologies have gained in importance, the filtration industry has a direct impact on creating a healthier, safer, and cleaner environment. Also, with increases in pollutants and allergens, filter media is a one-stop solution in protection from dust, hazardous gases and bacteria.

Owing to the new-found importance of filtration, filter media manufacturers, especially the big brands such as PARK Nonwoven, have an important role to play in delivering cutting-edge and innovative filter media products and solutions based on strategic research and development.

Our focus

Besides the traditional uses, PARK Nonwoven’s filtration solutions are focused on the use of activated carbon for odorful and harmful gas removal in the Fishery, Pharmaceutical, and Beverage industries. With high efficiency of dust removal in along with high efficiency towards removal of odor and gaseous contaminations, PARK filter media products are globally acknowledged and recognized for their quality. Further, eyeing the next phase of expansion, the company is geared-up to increase production of cabin air filter media products to meet high demand from the automotive industry.

Data-driven resolution

According to INDA’s Worldwide Outlook for the Nonwovens Industry report, nonwoven materials in the global filtration market will enjoy continuous growth, reaching beyond 747,000 million tons. Both developing and developed nations are continuously utilizing its innovations in urbanization, filtration systems, construction, water plants, power and heavy industry, communication, transportation and many others. With the market experiencing geographic expansion, PARK Nonwoven delivers cuttingedge products to solve old problems in modern and interesting ways.

Our portfolio

PARK Group offers a variety of air and liquid filter media that exceed various global standards, offering low pressure drop, energy savings and longer media life.

- Quality Testing: In-house testing lab for breathing resistance, tensile strength, elongation, GSM test, dust-holding capacity, particulate efficiency, pressure drop, pore size.

- Manufacturing Technologies: meltblown, needlepunch, chemical/thermal bond

- Air Filtration: Wide range of HEPA [(H10, H11, H12, H13, H14] ULPA Grades – (U15, U16); Pocket filter grades G3, G4, M5, M6, F7, F8, F9.

- Dust Bag Filter Media: (PET, PPS, P84, CPA, HPA, glass fiber, meta aramid, PTFE, PET pleatable)

- Engine Air Intake Filter: Engine air filter system helps in removing pollens, dirt, debris, dust aerosol from causing any damage. PARK filter media fulfil the requirements of EU9 and above.

- Liquid Filter Media with calendared and uncalendared grades, PP needle punch as well for 1 micron to 200 micron.

This content is sponsored by Park Nonwoven.