In the dynamic and global filtration industry, news and information is breaking on a daily basis. International Filtration News is tracking stories relevant to our industry from air and gas filtration to liquid filtration and the various end-uses for filtration technology. Here we will post news stories relevant to filtration and its downstream applications on an ongoing basis. Please check back for regular updates. Please check back for regular updates. If you have news that you feel should be added to this summary report, please email it to Matt Migliore at mmigliore@inda.media.

Most recent update: June 29, 2021

Mann+Hummel installs Filter Cubes to purify the air in Ludwigsburg, Germany

Mann+Hummel’s Filter Cubes are being installed along Ludwigsburg’s Schlossstrasse in Germany to provide clean air in the heavily trafficked area. When the project is completed, a total of 15 columns will reduce the concentration of fine dust and nitrogen dioxide along the street. The Filter Cubes are distributed over a total length of 250 meters.

Mann+Hummel’s Filter Cubes draw in the polluted air and bind over 80 percent of the nitrogen dioxide (NO2) and particulate matter (PM10). The heart of this technology is a combination filter, which comprises a highly effective particle filtration layer and activated carbon layers that adsorb nitrogen dioxide. These activated carbon media adsorb NO2 very effectively due to their large surface area. The technology is characterized by a particularly low pressure drop. As a result, it effectively cleans the air with very little use of energy. Thanks to their modular design, the Filter Cubes can be assembled to form a filter column.

Currently Mann+Hummel’s Filter Cubes are cleaning 1.96 billion liters of air per hour worldwide, according to the company. In terms of per capita consumption, this means that the 403 Cubes now installed (in total: 140 columns), providing purified air for 4.1 million people.

“Many people think intensively about the one kilo of food and the three liters of liquids they consume every day. But we very rarely think about the quality of the approximately 12,000 liters of air that each of us breathes every day,” says Jan-Eric Raschke, director Air Solution Systems at Mann+Hummel.

“We all agree, it would be best if our air was so clean that it didn’t need to be cleaned at all,” said Raschke. “Unfortunately, it is not. Cities and metropolitan areas in particular face enormous challenges. At MANN+HUMMEL, we have made it our mission for eight decades to separate the useful from the harmful. Providing clean air with state-of-the-art filter technology is one of our main goals.”

In addition to various locations in Germany, Mann+Hummel Filter Cubes are also used in Brazil, China, India and South Korea, among other places. Further projects are currently being planned in Hong Kong, Mexico, Colombia, Singapore, Taiwan and Thailand.

The first systems were installed in December 2018 in Stuttgart, the capital of the German state of Baden-Württemberg. In 2020, a scientific report that examined the effectiveness of the installations along the street Am Neckartor concluded that, on average, a reduction of nine percent in nitrogen dioxide pollution was achieved, and in the area of the sidewalk and close to the buildings even a decrease of ten to 19 percent. The studies focusing on particulate matter PM10 showed an average reduction of more than ten percent.

Source: mann-hummel.com

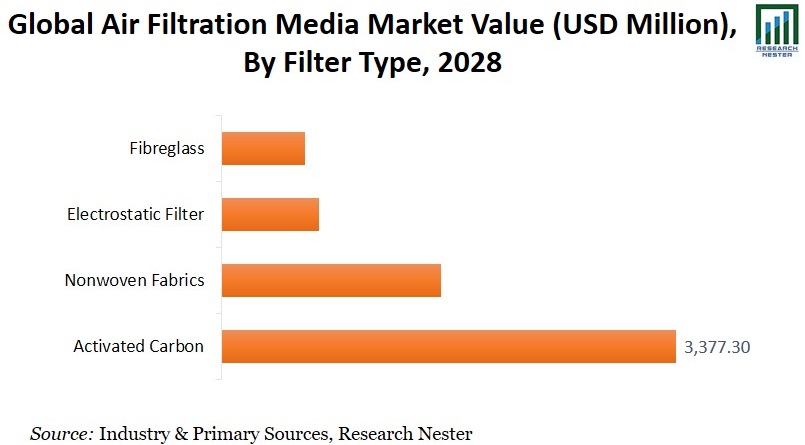

Global air filtration media market projected for 7.4% annual CAGR, reaching nearly $7B by 2028

According to a report by Research Nester, the global air filtration market generated revenue of $3.6 billion in 2019 and is anticipated to grow at a CAGR of 7.44% through 2028 to reach nearly $7 billion.

Much of this growth is being driven by growing industrialization worldwide and the need to control the emissions arising from industry, as well as more stringent regulatory requirements aimed at curbing air pollution. The market is also anticipated to grow due to increasing adoption higher-end HVAC systems, and air purifying systems in commercial and residential settings, along with advances in air filtration media products.

Based on geography, the reports segments the global air filtration media market into North America, Asia Pacific, Europe, Latin America, and the Middle East & Africa. The market in the Asia Pacific is anticipated to hold the largest market share of 42.0% in the year 2028 and grow with the highest CAGR of 9.01% during the forecast period. The growth of the market in the region can be attributed to the presence of several countries, such as India, Pakistan, China, and others, where the volume of air pollutants is often very high. In other statistics by the WHO, South Asia had the highest level of PM2.5 air pollution in 2017 as compared to other regions. In the year 2000, PM2.5 air pollution in the region was 78.9 micrograms per cubic meter, which increased to 82.9 micrograms per cubic meter in the year 2017. The statistics also stated that Nepal and India in South Asia were registered among the top ten countries with the highest mean exposure to ambient pollution.

The Asia Pacific air filtration media market is segmented by country into China, Japan, India, Australia, South Korea, South East Asia, and the Rest of Asia Pacific, out of which, the market in China is projected to register the largest revenue of $1.7 billion by the end of 2028. The market in the region is segmented by filter type into activated carbon, nonwoven fabrics, electrostatic filter, fiberglass, and others, out of which, the activated carbon segment is projected to hold the largest market revenue of $842 Million by the end of 2021. The Asia Pacific air filtration media market is also segmented by grade into HEPA, MERV, ULPA, and others, out of which, the MERV segment is anticipated to grow with the highest CAGR of around 10% during the forecast period.

The market in North America is anticipated to attain a market revenue of $1.1 billion by the end of 2021 with a CAGR of 6.25% during the forecast period. Increasing awareness of diseases caused due to air pollution, along with a rise in initiatives for regulating emission are cited as key growth drivers. The market in the region is further segmented by country into the United States and Canada, out of which, the United States air filtration media market is projected to grow with the highest CAGR of 6.37% during the forecast period. The North America air filtration media market is also segmented by media type into spunbond, needlefelt, meltblown, wet laid, and others, out of which, the meltblown segment is anticipated to grow with the highest CAGR of 7.83% during the forecast period. The market in the region is also segmented by reusability into washable/reusable and disposable, out of which, the disposable segment is anticipated to register the largest market revenue of $703 million by the end of 2021.

Read full details about this report: https://www.researchnester.com/reports/air-filtration-media-market/3070

Source: researchnester.com

Camfil releases 2020 Sustainability Report

Camfil, a global provider of air filtration engineering and manufacturing technology, released its annual Sustainability Report for 2020, covering four key business areas (filtration solutions, air pollution control, power systems, and molecular contamination control).

Highlights of the 2020 Sustainability Report include:

- A discussion of Camfil’s work towards furthering the United Nations’ Sustainable Development Goals

- Technological contributions to the healthcare sector during the global pandemic

- Cleanroom HEPA filtration system that won the Grand Indoor Climate Prize in Sweden

- Camfil’s new acquisitions and plans to construct new facilities across the world, and how these actions enhance the company’s mission

- An interview with Camfil’s CEO, Mark Simmons, who explains Camfil’s vision, goals, and values in detail

- Actions Camfil took during their first annual Clean Air Week, which began September 6, 2020, inspired by the UN’s international Clean Air Day

“The 2020 Sustainability report highlights and pays attention to protecting the health and wellbeing of our employees and the community during a challenging pandemic situation,” said Åsa Lidström, Camfil’s Quality and Environmental Initiatives Manager, “Camfil also acquired two companies in Australia and Sweden on the path to deliver as an industry leader in efficient clean air solutions. We have launched numerous initiatives to further improve energy and operational efficiency to reach our sustainability targets, thanks to our dedicated and committed team at Camfil.”

Read Camfil’s 2020 Sustainability Report: https://www.camfil.com/damdocuments/48120/1171580/brochure-sustainability-report-2020-eng.pdf

Source: camfil.com

DuPont, Waterise to collaborate on subsea desalination plants

DuPont announced that it has entered into a collaboration with Waterise to provide seawater reverse osmosis membranes and expertise to the company’s subsea desalination plants.

According to DuPont, subsea reverse osmosis (RO) desalination presents a sustainable and more economical way to turn seawater to freshwater. As subsea desalination leverages the natural hydrostatic pressure found at the depths of the sea to run the reverse osmosis, it reduces the energy requirements of conventional RO desalination by 40 percent. It also requires 80 percent less coastal land than land-based plants, presenting a viable option for communities with limited space. From an environmental perspective, subsea desalination requires lower amounts of pretreatment chemicals and eliminates the discharge of concentrated brine into coastal waters.

As Waterise’s patented desalination units reside on the sea floor, DuPont’s FilmTec seawater membranes were determined to be a good fit for this application.

“As we look to increase access to fresh water and enable a water optimized world, we are energized by opportunities to collaborate on innovative solutions to water purification, conservation and reuse,” said HP Nanda, global vice president and general manager, DuPont Water Solutions. “We are excited about Waterise’s new approach to desalination that not only reduces water scarcity, but also minimizes energy consumption and environmental impact.”

In addition to exclusively using DuPont’s FilmTec seawater membranes for all systems, DuPont and Waterise will share knowledge and expertise, as well as collaborate on research and development toward the mission to advance the subsea desalination operations and performance.

“I am delighted to announce that Waterise is collaborating with DuPont as part of our program to identify and establish collaboration with world leading companies which produce components needed to construct a Waterise desalination unit,” said Niels Petter Wright, CEO, Waterise.

Source: dupont.com/water.html

NX Filtration provides direct nanofiltration membranes for textile water recycling in India

Aquarius H2O Dynamics has selected NX Filtration to supply its hollow fiber direct nanofiltration (dNF) membranes for a water recycling application at Kewal Kiran Clothing Limited (KKCL). Aquarius H2O Dynamics will develop a water recycling plant at KKCL with a capacity of 700 m³ per day based on 32 dNF40 membrane modules from NX Filtration to remove color and reduce large parts of chemical oxygen demand (COD) and total dissolved solids (TDS) from wastewater. This will enable the reuse of wastewater in KKCL facilities.

“Earlier this year we piloted with NX filtration’s unique hollow fibre direct nanofiltration membranes, which impressed our customer KKCL with the superior water quality that we could produce,” said Sandeep Patel, director of Aquarius H2O Dynamics. “An additional benefit is the compactness and ease of operation of this solution, which can easily be integrated in their operations. The system based on dNF technology enables the direct treatment of the wastewater without intensive pre-treatment and can lead to over 95% recycling of the wastewater stream.”

“Our innovative hollow fiber direct nanofiltration membranes enable this simple and sustainable process of reusing industrial wastewater, significantly reducing the water footprint of KKCL,” said Manish Ghogle, sales manager of NX Filtration in India. “Compared to traditional wastewater treatment methods, we reduce the number of filtration steps, avoid the use of chemicals in the pre-treatment of the wastewater and significantly reduce energy use.”

Source: nxfiltration.com

Unifrax to acquire Lydall in deal valued at $1.3 billion

Unifrax, a global provider of high-performance specialty materials focused on thermal management, specialty filtration, battery materials, emission control and fire protection applications backed by Clearlake Capital Group, L.P. (“Clearlake”), has signed definitive agreements to acquire Lydall, Inc., a leader in the design and production of specialty filtration materials and advanced material solutions. With technologies and 23 manufacturing facilities around the world, Lydall is well positioned to capitalize on growth in clean air filtration and electric vehicle adoption, among many other attractive markets. Under the terms of the agreement, Lydall shareholders will receive $62.10 per share in cash for each share outstanding, implying a total enterprise value of approximately $1.3 billion.

“The combination of Unifrax and Lydall creates a global specialty materials platform with new cutting edge technologies in advanced filtration, electric vehicle battery systems, and energy saving applications,” said John Dandolph, President and CEO of Unifrax. “The addition of Lydall’s people, technologies, and assets to the Unifrax portfolio will help accelerate our innovation pipeline and creates a world class platform capable of solving the world’s most pressing energy consumption, environmental and filtration challenges. We are excited to partner with a company that is similarly focused on our commitment to a Greener, Cleaner, and Safer® world.”

Sara Greenstein, President and CEO of Lydall, added, “We are excited about the combination of Lydall and Unifrax. With this transaction, we are creating a leader in specialty filtration and advanced materials with over 250 years of combined expertise and experience delivering innovative and compelling solutions to customers worldwide.”

The transaction, which has been approved by the boards of directors of both companies, is expected to close in the second half of 2021 subject to the receipt of required regulatory approvals, including expiration or termination of the applicable waiting period under the Hart-Scott-Rodino Antitrust Improvements Act, approvals of Lydall stockholders and other customary closing conditions.

Source: unifrax.com

Metso Outotec introduces Life Cycle Services programs for filter users

Metso Outotec is launching four Life Cycle Services (LCS) programs for filtration to help overcome operational and process challenges. The programs are designed to simplify maintenance, improve filter reliability, minimize downtime, and maximize filter life.

“Metso Outotec LCS programs for Filters are designed to optimize operation of the filtration system, to overcome challenges such as failing to reach production targets or suboptimal product quality. Based on many years of experience in designing, building, delivering, operating, and maintaining filters, we know how to get the most from your assets throughout their entire life cycle,” said Tomas Hakala, senior vice president of Beneficiation & Dewatering, Services at Metso Outotec.

Programs include:

- Inspections and technical support program focuses on well executed annual maintenance, resulting in higher filter availability. This program is designed to ensure that equipment condition is well monitored, and correct maintenance actions and overhauls are efficiently executed for highest availability.

- Maintenance and reliability program covers all functional systems of the filter. This program spreads the complete maintenance activities across shorter, more manageable events on critical systems with the aim of ensuring that all important components and materials are covered.

- Rotable filter plate management program is designed to optimizes cost and ensure a high level of filter availability while taking care of plate and plate pack refurbishments. This program aims to minimize maintenance times and the lowest sustainable cost among the available options for our customers.

- Process optimization program is designed to ensure a high level of filter performance and optimized operation of the equipment. This program maximizes productivity and energy efficiency of customers’ filters by addressing specific plant challenges.

Source: mogroup.com

Filtration Group acquires Molecular Products; adds capability in life- and critical-care applications

Filtration Group acquired Molecular Products, a global provider of pure air technologies for customers in the healthcare, consumer and industrial technology, green energy and defense markets.

Molecular is focused on the design and manufacture of life critical devices for the treatment of breathable gases. The company has chemical and application expertise to deliver customized solutions that remove toxic, corrosive and harmful gases and produce breathable oxygen where it’s needed most.

The addition of Molecular Products enables Filtration Group to expand its presence in air filtration for life and mission-critical applications.

“We are incredibly excited to join Filtration Group. Their entrepreneurial culture and long-term focus on building market leaders is the perfect fit for Molecular,” said Troy Rhudy, CEO of Molecular Products. “This is a tremendous opportunity for us to continue leading the way in delivering technologies that save lives, protect critical environments and meet our customers’ most challenging air purification needs.”

“Filtration Group is the perfect home for Molecular, as our companies are aligned in mission and a people-focused, entrepreneurial culture,” said Filtration Group CEO Tim McCarty. “We are excited to partner with Troy and his innovative team and continue to make a greater impact on the world.”

Molecular Products product offering includes carbon dioxide absorbers, solid oxygen systems, impregnated activated carbon and specialty catalysts and zeolites. It serves customers in more than 90 countries from three manufacturing facilities, five sales offices and six regional logistics hubs.

Source: filtrationgroup.com

REXtac, DL Chemical partner to build 88M pound APAO plant in South Korea

REXtac LLC, of Odessa, Texas, has joined with DL Chemical of Seoul, South Korea, to establish a joint venture to construct and operate an amorphous poly alpha olefin (APAO) manufacturing plant located in Yeosu Industrial Complex in South Korea. With an investment of $134 million, the APAO plant will have an annual capacity of 88 million pounds per year. Groundbreaking on the new plant is scheduled to begin this year and will commercially operate in 2023.

APAO hot melt polymer and adhesive is widely used in a variety of applications, including hygiene products, HVAC filters, automotive interiors, and other industrial applications.

The joint venture will leverage DL Chemical’s global network to actively expand into the hot melt adhesive market, valued close to $10.4 Billion. This partnership will combine DL Chemical’s research and development capabilities with REXtac’s APAO manufacturing technology and R&D.

Nick Fowler, president of REXtac LLC, said, “REXtac is excited to be able to partner with a world class, experienced, petrochemical company, DL Chemical. The joint venture manufacturing capability will provide global service, supply, and delivery security to our ever expanding customer base and free REXtac USA from total dependency on North American propylene prices.”

DL Chemical is a specialized petrochemical company headquartered in Seoul, South Korea. REXtac LLC was founded in 2009 by an acquisition from Flint Hills Resources and Huntsman Chemical. REXtac LLC is a leader in manufacturing APAO and produces it through a proprietary catalyst and liquid pool production process.

Source: rextac.com

Xebec Adsorption completes acquisition of Tiger Filtration

Xebec Adsorption Inc., a global provider of clean energy solutions, announce it has closed the acquisition of all outstanding shares of United Kingdom-based Tiger Filtration (TFL). The acquisition of TFL will provide Xebec with a recurring aftermarket manufacturing business for elements and filters. TFL’s R&D capabilities will also allow for expansion of its product portfolio to include filtration products for hydrogen and renewable natural gas (RNG).

Founded in 2004 by former Walker Filtration employees (Bob Thompson, Gary Ashton and Matthew Rowe), TFL has gained worldwide recognition for providing high-quality alternatives for the compressed air and gas industry. TFL was established 17 years ago and has become an internationally active company with worldwide sales. Two of its principals will retire, and Gary Ashton will remain with TFL as managing director and continue his leadership in sales and business development.

Total consideration payable by Xebec is £12.0 million ($20.6 million CAD) and is subject to certain holdbacks, adjustments and time-based payments. TFL had revenues of £2.7 million ($4.6 million CAD), an EBITDA margin of 42% and a net income margin of 34% for FY2020. Xebec expects that TFL will immediately provide cost savings by displacing parts currently bought by its existing subsidiaries within the Cleantech Service Network, HyGear, Inmatec and its headquarters in Québec.

Source: xebecinc.com

Aquatech and Upwell Water create joint venture, Aquios, supporting an estimated $500M in water treatment infrastructure

Aquatech International announced the launch of its joint venture with Upwell Water. The new platform, Aquios, enables Aquatech to provide customers with water treatment and service with no upfront customer cost. Aquatech will also provide outsourced solutions through the platform, reducing the cost and risk of water operations while reaching sustainability targets. Aquios will also acquire and retrofit existing facilities to improve operating performance.

“The need for having long-term reliability, particularly as waters become more complex and difficult to treat, is paramount,” said Devesh Sharma, managing director of Aquatech. “Our partnership with Upwell will allow us to offer water technology as a service, providing a compelling solution to meet critical treatment needs with an accountable partner delivering a predictable cost of water operations and peace of mind to our customers. Our customers get what they need – reliability of water treatment and payment over time as they would for any utility service, but with a holistic approach integrating plant design and long-term operational service from a single provider. That makes getting better water treatment simple.”

Aquatech anticipates deploying capital to support over $500 million USD of water infrastructure through Aquios to help customers improve water and wastewater treatment over the next few years. Capstone Partners advised Aquatech on the transaction.

Source: aquatech.com│water.llc

Camfil celebrates 10th anniversary of Tech Center; highlights capability of two new filter lines

Camfil is celebrating the 10th anniversary of its Tech Center in Trosa, south of Stockholm in Sweden. The Tech Center covers an area of 2,500 square meters with five laboratories – an HVAC particle lab, a HEPA lab, a molecular lab, an indoor air quality lab and a gas turbine lab – all fitted with the latest equipment.

The Trosa Tech Center is the hub of a global research and development organization, focused on working to analyze indoor air and to test the performance of different filters. The center opened in 2010, but Camfil built Europe’s first test rig for HEPA filters as early as 1967.

Anders Sundvik, vice president of R&D at Camfil, said: “As a business, we continue to invest heavily in research and development in order to innovate in the creation of sustainable products at the leading edge of technology. Clean air plays a massive part in many industries in terms of productivity and quality but, most importantly, it offers significant benefits for all humans’ health and wellbeing. The products that Camfil develops make an enormous contribution to this. The third perspective is environmental concerns by offering the lowest possible energy usage. However, Camfil refuses to rest on its laurels. Camfil has proven that it remains at the forefront of technology with the launch of two major filtration products – Megalam EnerGuard and Absolute V, the next generation HEPA filters for sensitive processes.”

Both new filter lines are designed to increase safety and productivity while also reducing energy consumption.

Megalam EnerGuard is a terminal HEPA/ULPA filter for cleanrooms with lower total cost compared to glass fiber and other competitive filters, through a longer service life, energy cost savings, operational efficiencies and manufacturing process integrity.

It contains a unique media that significantly decreases the chances of filter leaks and resultant room contamination in cleanrooms (first installations achieved 0% failure) to avoid the expensive costs of a product failure due to any mishandling.

Absolute V high airflow HEPA filters, meanwhile, are the energy-efficient filters that provide optimal protection with minimal total cost of ownership when installed in air handling units or in-line HEPA housings. With the Absolute V filter, Camfil placed a special focus on optimizing weight, robustness and energy consumption.

Source: camfil.com

Mann+Hummel releases 2020 financial report

Mann+Hummel released its 2020 financial statement, showing a decrease in turnover and an increase in earnings before interest and taxes (EBIT) and EBITDA. The company ended the year with a turnover of 3.8 billion euros, compared to 4.2 billion euros in 2019. It also saw a decline in global automotive production at 16.9% less compared to the previous year.

EBIT resulted in 165 million euros, which is above the previous year’s figure of 153 million euros. EBITDA increased to 404 million euros, up from the 2019 EBITDA of 387 million euros. The EBIT margin improved 0.7% from 3.6% 2019 to 4.3% in 2020.

2020 was the first year under the new management board for Mann+Hummel. Since January 2020, Kurk Wilks, president and CEO, is leading the Group alongside executive vice president and chief financial officer Emese Weissenbacher and chief operating officer Nic Zerbst. Mann+Hummel also acquired Helsatech GmbH and Helsacomp GmbH in September 2020, expanding into activated carbon technology and the production of elastomer membranes.

“We responded promptly to the coronavirus pandemic and implemented comprehensive protective measures at all plants. This has prevented major production losses. Of course, we were also affected by supplier shortages, but we were able to handle these well through effective process management,” said Zerbst.

Source: mann-hummel.com

Camfil USA relocates Nashville branch to larger facility

The Nashville Branch for Camfil USA has moved to a new and larger facility located at 1305 Elm Hill Pike. The branch officially began operations at the new location in May 2021.

“The 15,000 sq. ft. facility includes the largest local inventory of the most common air filter styles and sizes along with HEPA air filters for hospitals and other critical use areas,” said Adam Wiggins, Camfil Nashville Branch Manager. “We have a brand new city counter where contractors can grab a cup of coffee in the morning when picking up filters for the day. The facility has two dock doors for tractor-trailers and straight trucks, as well as a roll-up door for vans and pickups.”

The Camfil Nashville Branch facilities are equipped with the following capabilities:

- Custom filter sizes made local on-site

- Custom poly media rolls, blankets, and pads made local on-site

- Delivery service available

- Contractor city counter service

- Air filter installation service

- HVAC energy impact analysis

- Air filter life cycle testing

Source: camfil.com

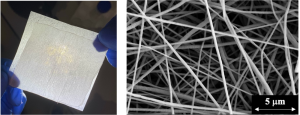

Polymer nanothread filter captures 99.9% of coronavirus aerosols in experiment

A filter made from polymer nanothreads captured 99.9% of coronavirus aerosols in an experiment.

“Our work is the first study to use coronavirus aerosols for evaluating filtration efficiency of facemasks and air filters,” said corresponding author Yun Shen, a UC Riverside assistant professor of chemical and environmental engineering. “Previous studies have used surrogates of saline solution, polystyrene beads, and bacteriophages — a group of viruses that infect bacteria.”

The study, led by engineers at UC Riverside and The George Washington University, compared the effectiveness of surgical and cotton masks, a neck gaiter, and electrospun nanofiber membranes at removing coronavirus aerosols to prevent airborne transmission. The cotton mask and neck gaiter only removed about 45%-73% of the aerosols. The surgical mask did much better, removing 98% of coronavirus aerosols. But the nanofiber filter removed almost all of the coronavirus aerosols.

Shen and George Washington University colleague Danmeng Shuai produced a nanofiber filter by sending a high electrical voltage through a drop of liquid polyvinylidene fluoride to spin threads about 300 nanometers in diameter — about 167 times thinner than a human hair. The process created pores only a couple of micrometers in diameter on the nanofiber’s surfaces, which helped them capture 99.9% of coronavirus aerosols.

The production technique, known as electrospinning, is cost effective and could be used to mass produce nanofiber filters for personal protective equipment and air filtration systems. Electrospinning also leaves the nanofibers with an electrostatic charge that enhances their ability to capture aerosols, and their high porosity makes it easier to breathe wearing electrospun nanofiber filters.

Read the full story: https://news.ucr.edu/articles/2021/05/17/nanofiber-filter-captures-almost-100-coronavirus-aerosols

Source: ucr.edu

Indiana approves UV light air purification system for school buses

The Indiana State School Bus Committee approved the use of UV light air purification systems on Indiana school buses after a successful pilot program with Indiana-based Lumin-Air.

Andrew Desmarais, Chief Operating Officer of Lumin-Air said, “This approval is very exciting for Indiana school districts and puts Indiana on par with other states who have already approved these technologies to help provide clean air in their school buses. Most importantly Indiana schools can now implement a solution to help reduce the risk of transmission and better protect students, bus drivers and other school bus occupants against airborne respiratory pathogens like SARS-CoV-2 and Influenza.”

School buses are the most densely populated areas in a school’s facility and typically have the poorest air quality. Lumin-Air’s system includes MERV 13 filtration and UV lights in an enclosure, circulating clean, disinfected air throughout the bus. This is a much safer and healthier alternative to opening school bus windows, which can bring in unfiltered air containing exhaust, allergens, and particulates. The U.S. Environmental Protection Agency (EPA) urges limiting inhalation of diesel exhaust especially for children who still have developing pulmonary systems.

Timing for approval was critical as Indiana schools have until June 25th to turn in proposals for how they will allocate the large amount of Elementary and Secondary School Emergency Relief funds (ESSER) to improve air quality in their facilities and school bus fleets.

Lumin-Air has installed its solution in California, Pennsylvania, Florida and Maryland, on all major school bus manufacturer models and on two leading metro bus manufacturer’s vehicles. They also have a pilot program underway on a rail system.

Source:  lumin-air.com

lumin-air.com