In the dynamic and global filtration industry, news and information is breaking on a daily basis. International Filtration News is tracking stories relevant to our industry from air and gas filtration to liquid filtration and the various end-uses for filtration technology. Here we will post news stories relevant to filtration and its downstream applications on an ongoing basis. Please check back for regular updates. If you have news that you feel should be added to this summary report, please email it to Ken Norberg: ken@filtnews.com

Most recent update: February 29, 2024

Radhika Fox Appointed Senior Advisor at Xylem

Xylem Inc., a leading global water technology company dedicated to solving the world’s most challenging water issues, announced the appointment of Radhika Fox as Senior Advisor to the Company.

“Radhika is one of the world’s most insightful and effective champions of water – a universally respected voice for solutions to society’s biggest water challenges,” said Matthew Pine, Xylem president and CEO.

Fox will provide strategic counsel to Xylem on evolving issues and opportunities in the water sector and provide advice on a range of matters to support the delivery of Xylem’s strategy. Fox most recently served as the Senate-confirmed Assistant Administrator for the US Environmental Protection Agency’s Office of Water, acting as chief advisor to the EPA Administrator and White House on water resources and water infrastructure in the United States.

Prior to joining the EPA, Fox served as the Chief Executive Officer for the US Water Alliance, a non-partisan network that unites diverse stakeholders on common-ground solutions to the nation’s pressing environmental, water, and climate challenges. Her career in water began at the San Francisco Public Utilities Commission – a public agency that provides water, wastewater, stormwater, and electric power services to over 2.6 million people in the San Francisco Bay Area.

NX Filtration Supplies Chinese Coffee Chain Luckin’s Water Treatment Plant

NX Filtration, a leading provider of advanced water filtration membrane solutions, announced that it has supplied its hollow fiber nanofiltration membrane modules to the Luckin Coffee water treatment project together with its OEM partner Suzhou MOPU in China.

The advanced membrane system marks a significant milestone for both companies in addressing the unique water filtration needs of Luckin Kunshan’s bakery plant in Kunshan, Jiangsu Province. One of the key factors that contributed to the use of NX Filtration’s technology is the company’s dedication to environmental responsibility.

Luckin Coffee, the No. 1 coffee chain shop in China with over 10,000 sub-branches nationwide, operates a bakery plant in Kunshan for delivery to Luckin Coffee sub-branches. A crucial requirement in the production process is the use of the highest quality water with a Total Dissolved Solids (TDS) level of around 20.

A unique ambition of the Kunshan bakery plant is to treat its wastewater stream well, given its status as a top-notch food production facility. NX Filtration was awarded this project due to the distinctive advantage of its sustainable nanofiltration membrane technology, which eliminates the need for chemical dosing in the water treatment process, whilst maintaining healthy minerals in the water.

DuPont Launches New Nanofiltration Elements for Dairy Processors

DuPont Water Solutions has launched the new FilmTec™ Hypershell™ NF245XD range of nanofiltration elements for use in the dairy industry. The durable elements are purpose-designed for use in long-lasting and efficient solutions for the separation and demineralization of milk and whey streams.

“The sanitary full-fit design of FilmTec™ Hypershell™ elements is specifically designed for food and dairy processing applications to help reduce the volume of water and energy consumed when concentrating milk and separating lactose or whey” said Yolanda Cuenca, Global Technical Leader Dairy.

“OEMs, plant managers, and operators across the dairy ingredients industry are constantly seeking more cost-effective separation and demineralization solutions,” said Arturo López, Global Marketing Leader Dairy. “FilmTec™ Hypershell™ NF245XD elements can help them maximize operational efficiency by improving product yield while consuming less energy than alternative solutions.”

London to Install Air Filters in Schools

London, UK Mayor Sadiq Khan has announced plans to fit PM2.5 filters in 200 schools, aiming to improve air quality for children’s health, with potential for wider implementation if successful.

Mr Khan said: “I want every single child to breathe clean air in and around their school.”

He added: “In those vital early years, the difference to young people’s health and well-being can be life-changing.”

The pilot is expected to cost £2.7m and forms part of the mayor’s 2024/25 budget, which will be voted on by the London Assembly on Thursday.

The funding will pay for the filters and their maintenance, school engagement, educational materials and monitoring the impact of the program, City Hall said.

Daniel Kebede, general secretary of the National Education Union, said the pilot would be a “massive benefit to pupils and staff in London schools”.

He called for the scheme to be “taken up more widely across the country”.

City Hall said the schools chosen for the pilot would be spread across London and selected based on pollution levels, as well as those in more deprived areas.

Donaldson Announces Record Sales of its Popular Inlet Barrier Filter

Donaldson Aerospace & Defense, a division of Donaldson Company, Inc., announced record sales of its industry leading inlet barrier filter (IBF), and invites customers to Heli-Expo Booth #8102 to see the first ever display of its Leonardo AW169 IBF.

“The success of our IBFs is testament to our ongoing commitment to our helicopter OEM customers—listening to them and continually adding new products to support the industry,” said Tom Newman, Donaldson rotorcraft business director.

Year-over-year sales increases for IBFs have also benefited by continued sales strength in defense aircraft and helicopter emergency medical services (HEMS).

Donaldson first launched its cost-saving IBF in 2001, which revolutionized engine protection for helicopter operations, especially those conducted in particularly harsh, off airport locations. Reduced engine maintenance costs, consistent flight operations and extended engine time on wing are experienced by aircraft operating with Donaldson’s IBF onboard.

In addition to the Leonardo AW169 IBF, Donaldson will be exhibiting its Bell 407 Inducer Vent Filtration System and most of its legacy IBF systems in booth #8102 at Heli-Expo 2024 in Anaheim, California, Feb. 27-29.

www.donaldsonaerospace-defense.com

High Performance Stainless-Steel Filters

Biotech Fluidics AB of Sweden announced a new range of multilayer stainless-steel filters for larger bore elevated temperature and corrosive processing applications. Benefiting from proprietary “Closed Edge Technology” these unique PORO–FRIT™ filters deliver an unmatched even flow through profile even at the filter edges.

The filters are available in a wide range of diameters from 20-200 mm, with a porosity between 2 and 20 microns. These multilayer sintered wire mesh filters are self-standing and inherently stable. Delivering market leading performance, these filter elements can lower your costs by providing longer on-stream life and years of trouble-free service. In addition, Biotech Fluidics multilayer stainless-steel filters are easily cleaned thereby reducing your disposal costs.

Amazon Filters Launches Sustainable Polypropylene Filter Media

Amazon Filters has become the first industrial filter maker in the UK to use polypropylene manufactured from renewable resources in production of meltblown filter media. The Surrey-based manufacturer has launched sustainable polypropylene versions of its flagship ranges SupaSpun II, SupaGard, Contour and VisClear II.

These filters are widely used in critical liquid filtration processes in industries such as municipal water, oil and gas, food and beverage, chemicals and coatings, and pharmaceuticals. Traditionally, monomers sourced from fossil fuels have been the base media feeding into the polymers involved in polypropylene manufacturing.

But now, under a ‘mass balance approach’ developed by Vienna-headquartered Borealis, a world leader in polymer development and manufacture, a proportion of the fossil-derived propane can be replaced by an identical volume of sustainable monomers that are tested to ensure the same level of quality. Amazon Filters’ product variations involve Borealis’ Bornewables polymers made from sustainably sourced renewable feedstocks. They are derived solely from waste and excess vegetable oils such as used cooking oil and residues from vegetable oil processing.

The approach has already been used in polypropylene manufacture by early adopters in the Netherlands, including in the production of medical face masks and other filter media. Describing the process, Amazon Filters Managing Director Neil Pizzey said raw waste vegetable oil collected from restaurants and the food industry is used to make the monomers that feed into the polypropylene manufacturing process in the same way as monomers sourced from fossil fuels.

GEA Invests EUR 18 Million in Technology Center for Alternative Proteins in the USA

GEA is investing EUR 18 million (USD 20 million) in a technology center for alternative proteins in Wisconsin, USA. The new food tech hub will pilot microbial, cell-based and plant-based foods. GEA’s state-of-the-art technologies and a team of biotechnology experts form the basis for scaling new food for industrial production, which is increasingly in demand in the USA. Groundbreaking at the new GEA campus in Janesville is scheduled for spring of 2024, with the opening to follow one year later.

Technology boost for the U.S. new food market

The USA is one of the countries promoting the development of sustainable food options through favorable regulation and openness to innovative food technologies. For example, the Food and Drug Administration (FDA) already approved cell-cultivated chicken meat in 2022 and last year confirmed that the use of precision-fermented milk proteins in foods is safe.

DuPont Membranes for Lithium Brine Purification Named 2024 Edison Awards™ Finalist

DuPont announced that FilmTec™ LiNE-XD nanofiltration membrane elements, the company’s first offering dedicated to lithium brine purification, was named a finalist in the 2024 Edison Awards™ in the Resource Recovery & Environmental Conservation category.

Lithium brine purification is critical to producing batteries needed for electrification to help combat climate change. FilmTec™ LiNE-XD elements can help enable lithium production from resources such as salt lake brine, geothermal brine, and surface and sub-surface clay. FilmTec™ LiNE-XD nanofiltration membrane elements are designed to withstand harsh conditions while also yielding high recovery of both lithium and water; requiring less energy than other methods.

“With a future powered by batteries, the demand for lithium continues to rise rapidly—and so does demand for cleaner and more efficient extraction methods that can be made possible by membranes,” said Verónica Garcia Molina, Global Marketing Leader, Industrial Water & Energy, DuPont Water Solutions.

The durability, selectivity and permeability of FilmTec™ LiNE-XD nanofiltration membrane elements can help enable lithium mining operations, including emerging applications such as direct lithium extraction (DLE), to help enhance lithium yield, reduce energy consumption and increase membrane lifetime compared to conventional nanofiltration membranes. Additionally, cleaning, chemical usage and disposal can be reduced in downstream lithium concentration thanks to its efficient removal of scaling impurities.

The Edison Awards™ is an annual competition honoring excellence in new product and service development, marketing, human-centered design, and innovation. The gold, silver and bronze winners will be announced at the 2024 Edison Awards Gala in Fort Myers, Florida, on April 18, 2024.

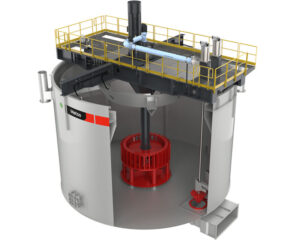

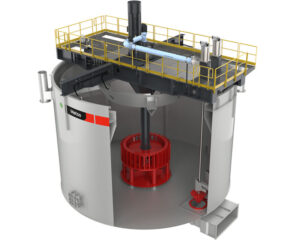

Metso to Provide Concentrator Plant Equipment for Copper Project in Chile

Metso has been awarded a major order to deliver key concentrator equipment for a copper mining project in Chile. The value of the order is approximately EUR 55 million, and it is booked in the Minerals segment’s first-quarter 2024 orders received.

The Metso delivery scope consists of high-capacity Nordberg® MP1250 secondary cone crushers, MF SeriesTM vibrating screens and energy-efficient Vertimill® VTM1500 regrinding mills. For the flotation and separation circuit, Metso will supply multiple TankCell® and ColumnCellTM flotation cells featuring several of the largest available 630 m³ TankCell® units, as well as HCTTM High Compression tailing thickeners. In addition, Metso’s scope includes four MHC hydrocyclone clusters, of which two will be among the largest in the world. Most of the products in the delivery scope are part of Metso’s Planet Positive offering.

De.mem Receives First Order for Graphene Oxide Enhanced Membrane Cartridges

Australian headquartered, international water technology company De.mem Ltd. announced that the Company has received the first sales contract for its recently developed Graphene Oxide (“GO”) enhanced membrane technology. The order is a significant milestone as it is the first commercial quantity of Graphene Oxide enhanced membrane cartridges supplied to a customer.

Based on the order, De.mem will supply its GO enhanced membrane cartridges to Grafoid, Canada, the parent company of Purafy, Canada. Grafoid/Purafy is De.mem’s partner for domestic water treatment applications in North America. The order is valued at approximately $55,000 in revenues for De.mem. This order commences the commercial launch of De.mem’s GO membrane technology through the

partnership with Purafy. The membrane cartridges will be deployed by Grafoid/Purafy for applications that do not require National Sanitary Foundation (NSF) approval.

Ingersoll Rand Acquires Friulair to Expand Air Treatment Capabilities

Ingersoll Rand Inc., a global provider of mission-critical flow creation and industrial solutions, has closed on the acquisition of Friulair S.r.l. in an all-cash upfront purchase price of approximately $146M.

Based in Italy, Friulair is recognized globally for its design and production of dryers, filters, aftercoolers, and accessories for the treatment of compressed air as well as its chiller product line. The addition of Friulair will increase the scale of Ingersoll Rand’s air dryer business, significantly increasing the company’s access to the original equipment manufacturer channel and will add new chiller production capabilities. It also adds manufacturing locations in Cervignano del Friuli, Italy and Si Racha Chon Buri, Thailand.

Friulair employs approximately 215 people and has approximately $65 million in revenue. Through the realization of synergies and the deployment of IRX, Ingersoll Rand expects to realize Adjusted EBITDA margins in excess of 30% by year three of ownership.

“Acquiring Friulair will give us the opportunity to accelerate growth across food and beverage and pharmaceutical end markets, in addition to scaling our existing air treatment business,” said Vicente Reynal, chairman and chief executive officer of Ingersoll Rand. “I am excited to welcome the Friulair team into the Ingersoll Rand family.”

Friulair will join Ingersoll Rand’s Industrial Technologies and Services (IT&S) segment.

Suez Secures Water Treatment Plant Project in Indonesia

SUEZ, a leading player in water management, recently signed a contract for the Buaran III Water Treatment Plant (WTP) project in Jakarta. The Group will supply key equipment for the water treatment process and will provide technical advisory services for the installation and commissioning of the Buaran III utility. The new WTP in the Indonesian capital will enhance the resilience of the city’s water supply system to provide a safe, reliable, and long-term supply of water to local communities.

Currently, Jakarta’s WTPs can treat 1.47 million cubic meters daily, supplying 65% of urban areas with clean water. The city’s government is aiming for total urban clean water coverage of 100% by 2030, planning new WTPs to meet rising demand with an additional 960,000 cubic meters per day. The completion of the Buaran III WTP, expected in first half of 2025, will boost progress towards this goal. It will provide an additional 260,000 cubic meters of clean water per day to communities in Jakarta, accounting for approximately 28% of the incremental water capacity needed to meet the 2030 target.

In Jakarta, raw water turbidity can deteriorate significantly during the rainy season, severely affecting clean water availability in urban communities. As the key technology supplier in this project, SUEZ will provide essential equipment for the water treatment process, as well as technical advisory services for installation and commissioning. SUEZ’s patented Densadeg™ settler and Aquazur® V filter will be used innovatively to ensure the project’s water treatment capacity and quality. This is the first time that Densadeg™ is being deployed in Southeast Asia.

Centrisys/CNP Opens New Engineering Innovation Lab

North American manufacturer of decanter centrifuges and advanced biosolids treatment technologies Centrisys/CNP has opened its new engineering innovation lab designed to enhance collaboration, streamline problem-solving, and foster innovation across all engineering departments.

The engineering innovation lab was conceived as a hub for its engineers to come together from project inception to completion, ensuring swift response times and unified goals. The lab serves as a space for knowledge transfer and as a training ground for the next generation of engineers.

Equipped with technology such as advanced computer systems and SolidWorks software, the lab is about uniting mechanical, electrical, process, and application engineering departments. The lab features collaborative spaces such as drop-down areas, a conference room, and a kitchen island designed to foster interaction. From the upstairs lab space dedicated to mechanical, electrical, applications, and process engineering to the first floor’s projects team, the layout will help ensure integration and access between teams, optimizing the execution of projects.

FLSmidth to Explore Divestment Options for its Cement Business

FLSmidth announced that the company will explore the available divestment options for the Cement business. The objectives are to enable the Cement business to maximize its full potential as well as to further strengthen their Mining business’ market-leading position as a full flowsheet technology and service provider to the global mining industry.

As announced on 18 January 2023, FLSmidth has introduced pure play strategies to separate its Mining and Cement businesses. Additionally, long-term financial targets have been announced for each of the two businesses. As of 1 January 2024, the new company structure is in place and the remaining separation activities are expected to be completed during the first half of 2024.

The Mining and Cement businesses are very different in terms of market dynamics and industry fundamentals. In addition, the synergies, overlap in customer base and overlap in product offerings between the two businesses are limited. Consequently, by separating the two businesses, both will benefit from increased operational flexibility, strong accountability and improved financial transparency. This allows them to focus on their own unique opportunities and challenges, and thus maximise their respective full potential.

Over the past year, FLSmidth has simplified and rightsized the Cement business to further strengthen its market-leading position, improve profitability and make it fit-for-purpose with a strategic focus on the core products and services required in the cement industry.

Willow Industries Introduces Innovative Air Filtration System

Willow Industries, the leader in cannabis decontamination technology and microbial control services, announced the launch of WillowAir, an air filtration system designed to capture and remove airborne contaminants, providing safer workplaces for employees and a direct solution to one of the main factors in contaminated product: Air Quality.

Addressing the industry’s heightened need for employee safety, Willow Industries has once again engineered a science-backed and cost-effective solution to the evolving needs of the industry. The WillowAir system effectively counters inhalation hazards of ground cannabis dust, respiratory irritants, airborne pathogens like Aspergillus, and overall health risks in cultivation environments. As a multifunctional system, WillowAir plays an equally crucial role in combating the pervasive threat of airborne contaminants affecting plant quality, product safety, and regulatory compliance. By lowering exposure to microbial burden and cross-contamination, the system proactively maintains a clean environment throughout upstream processes.

Demand for Sulzer Chemtech’s Licensed Technologies Surges in North America

A rapidly growing number of oil and gas processing facilities across North America is leveraging Sulzer Chemtech’s licensed solutions to enable major boosts in sustainability and productivity. This surge in demand highlights the pivotal role and acceptance of the company’s advanced technologies in driving efficiency and profitability.

As part of its most recent collaboration, the global leader in separation and mixing technology is implementing an integrated setup on the Gulf Coast, U.S., that reduces emissions and energy usage while maximizing the ability to extract valuable refinery products.

Sulzer Chemtech offers a comprehensive range of licensed technologies, such as GT-LPGMax™, GT-BTX™ and GT-BTX Plus™, that are designed to efficiently recover large volumes of valuable, high-purity refinery products. This diverse portfolio is strengthening Sulzer Chemtech’s role as a preferred partner for processors looking at addressing current market demand for more sustainable products and practices while improving profitability and competitiveness.

In its latest project, Sulzer Chemtech is helping a leading U.S. refinery debottleneck its saturated gas plant while improving the recovery of propane and isobutane and reducing the cost of consumables. The resulting products can either be used to improve the feed to the refinery’s alkylation unit, further reducing costs, or sold on the open market, enhancing current revenue streams.

ABB Launches New Process Automation Solution for Cold Block Stage of Beer Production

ABB has launched its technology solution for the cold block stage of the brewing process to further support breweries in their operational efficiency and in the adoption of digital solutions.

Following the introduction of its ABB Ability™ BeerMaker intelligent process automation control solution for hot block, ABB has launched its technology solution for the cold block stage of the brewing process to further support breweries in their operational efficiency and in the adoption of digital solutions. ABB’s expert brewmaster developed the solution with a broader team of domain experts.

The cold block stage of the brewing process involves fermentation and maturation, yeast management, filtration, bright beer tanks (BBT) area, cleaning in place (CIP), and all secondary processes. These are the stages at which variations in recipe and flavor can be managed and introduced, which is particularly important to brewers. ABB uses modular automation, digital capabilities, simulation technology, and advanced process control (APC) to ensure the solution will support customers’ current challenges and future developments.

It will benefit customers who require a solution to improve and optimize their processes, reduce their energy and water consumption, and increase productivity. The solution is based on the ABB Ability™ System 800xA® distributed control system (DCS).

With its primary focus on breweries, ABB Ability™ BeerMaker provides users with a technological package of ready-made and tested master recipes, processes, templates, and objects that can be easily adapted to their needs by using a variety of configuration/recipe parameters and control schemes. Brewmasters receive a powerful production tool that imposes no limits on their production schedules or creativity.

Ahlstrom Plans to Invest in a New Production Line for Molecular Filtration Media

Ahlstrom pursues its over 50-year commitment and drive of the future of the global filtration industry by investing in a new production line for molecular filtration media in Turin, Italy.

Air quality in closed environments such as buildings and vehicles is a major concern in many areas of the world. In this context, particulate filter media play an important role in removing solid particles and aerosols from the air. Molecular filter media are used in complement, removing gaseous pollutants, including volatile organic compounds, inorganic gases (such as sulfur dioxide, nitrogen oxides, ammonia), and odors, and delivering the cleanest air to people and processes.

The new line is being designed to produce the highest-performance adsorbent materials for premium filtration applications, including next-generation cabin air and fuel cell air intake, as well as a complete range for HVAC and cleanrooms. It will enable Ahlstrom to offer superior solutions for customers and support their industrial filtration application development as well as the transition to electric vehicles.

The investment is made in synergy with Ahlstrom’s Fine Fiber platform in Turin, which will be upgraded to produce HEPA filtration layers. Fine Fiber media can be combined with molecular filtration materials also to deliver the best protection against the finest particles.

Davis-Standards Completes Acquisition of Extrusion Technology Group

Davis-Standard, LLC, a global leader in the design and manufacturing of extrusion and converting technology, announced that it has completed the previously announced acquisition of Extrusion Technology Group (“ETG”).

The acquisition includes three esteemed brands: battenfeld-cincinnati, Exelliq, and Simplas. These additions officially join the Davis-Standard family, marking a significant milestone in the company’s strategic expansion.

The acquisition further strengthens Davis-Standard’s position as an industry leader, combining its expertise with the innovative technologies and market presence of battenfeld-cincinnati, exelliq, and Simplas. With a shared commitment to excellence, the unified team is poised to deliver unparalleled solutions and support to customers worldwide.

Integrating these renowned brands into the Davis-Standard portfolio brings a wealth of knowledge, experience, and advanced technologies. Customers can expect an expanded product offering, increased service capabilities, and a broader geographical presence to serve their unique requirements better.

Davis-Standard remains committed to delivering value to its customers, partners, and stakeholders. The company is enthusiastic about the opportunities that this acquisition creates for collaboration, innovation, and growth.

FTS and Jewett Automation Merge

As of February 1, 2024, Filtration Technology Systems (“FTS”) has merged with Jewett Automation, LLC of Richmond, Virginia. This business merger is part of an ongoing efforts to be the leading filtration automation business by offering best-in-class standard products, unique custom automation solutions, superior customer service and dedicated aftermarket support, the company said. FTS will continue to operate as Filtration Technology Systems.

Puraffinity Wins Award

Puraffinity, which develops precision technology for the removal of PFAS ‘forever chemicals’ across multiple water treatment applications, has won a $250,000 award from the Morgan Stanley Institute for Sustainable Investing.

In addition to the financial award, Puraffinity receives a yearlong collaboration with the Institute for Sustainable Investing which will help them grow and scale up their innovative solution.

Puraffinity, which is tackling the human health and environmental challenges of per-and polyfluoroalkyl substances (PFAS) has developed a suite of adsorbent materials, exhibiting high selectivity towards diverse PFAS compounds. These are adaptable for multiple applications. The company has a goal to provide one billion people with PFAS-safe water by 2030.