Efficiency is crucial in the manufacturing industry, where time is money. For success, it is essential to produce products quickly and efficiently; this is where automation plays a vital role.

Investing in ELSNER’s automated filtration manufacturing machinery can save valuable time and resources, increase productivity, and consistently manufacture superior products. ELSNER’s machines are trusted by numerous industries worldwide, with over 3000 machines operating across 60 countries. Since the early 2000s, ELSNER has been providing solutions to the filtration industry, earning a reputation as a leader in the field. ELSNER’s experience and expertise can help you overcome your most significant challenges and meet the demands of your customers.

Increase Productivity and Quality:

It is important to recognize that automation can significantly reduce human error, leading to increased quality, precision, and accuracy within your company. Automated processes can efficiently handle repetitive tasks, ensuring greater uniformity and conformity while allowing employees to focus on more stimulating tasks, increasing company morale. Automated processes are generally more efficient than manual operations, resulting in increased productivity, decreased unit costs, and higher throughput. Our utilization of robotics to apply glue patterns reduces operator fatigue. Taking the arduous task of bead placement out of the operator’s hand frees them to focus on higher-quality tasks and prevents burnout.

Saving Time and Resources:

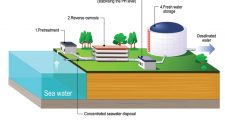

Manufacturers have struggled with labor pressures for decades, but the Covid-19 pandemic further highlighted the labor shortage issue. Automation presents a solution that allows companies to operate with a smaller staff while enabling employees to utilize their skills more effectively. By automating tasks such as membrane folding, outerwrap tape application, and glue bead placement, employees can focus on more advanced tasks that require a higher skill set. This improves productivity and creates opportunities for upskilling and career advancement within the organization.

A Look at ELSNER Filtration’s Solutions:

ELSNER filtration automated machinery includes:

- Automatic Membrane Folding: The EMF-42 automatically converts membrane and plastic mesh into folded “leaves.”

- Filter Assembly and Rolling: The APB-42 provides automatic pack building for filter components.

- Filter Rolling and Gluing: the SFR-42 automates tasks such as glue delivery and outer wrap tape for spiral wound membrane filers.

- Filter Element Finishing: the Element Trim Saw is designed to finish the edges of industrial liquid filtration elements.

Want to learn more about how ELSNER automation can help you? Contact us at eew@elsnereng.com.

This content is sponsored by Elsner Engineering