Deciding which HVAC filtration solution is the best choice requires a comprehensive understanding of your system needs and the costs associated with HVAC filtration. Simplifying the decision-making process is an attainable goal, but it requires necessary steps. Whether it is the age of a unit, the layout of a facility, the space allotted for filters (and changeouts), the system workload or other parameters, seeing beyond the upfront sticker price to the total cost is critical.

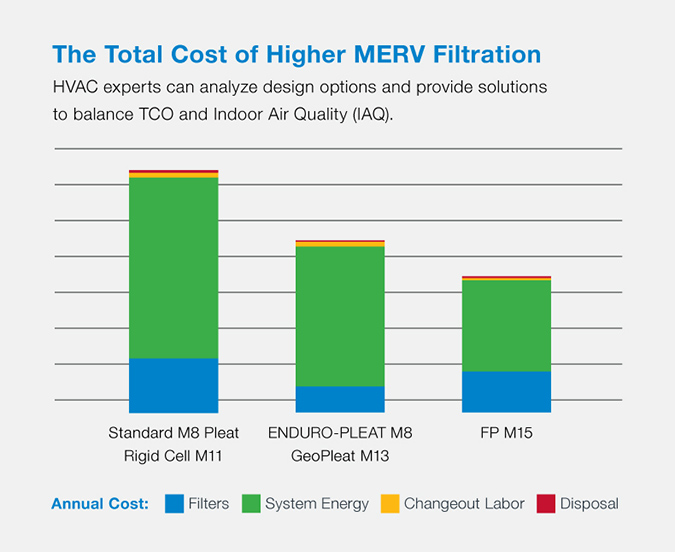

Total Cost of Ownership (TCO) is gaining recognition as industries become more competitive and financial operations are painstakingly scrutinized. TCO combines the cost of purchasing a filter or comprehensive HVAC solution with the overall operational costs, including the energy consumed to move air through the filter, changeout labor and disposal. TCO informs the purchaser and provides a complete overview of every implication and/or potential scenario.

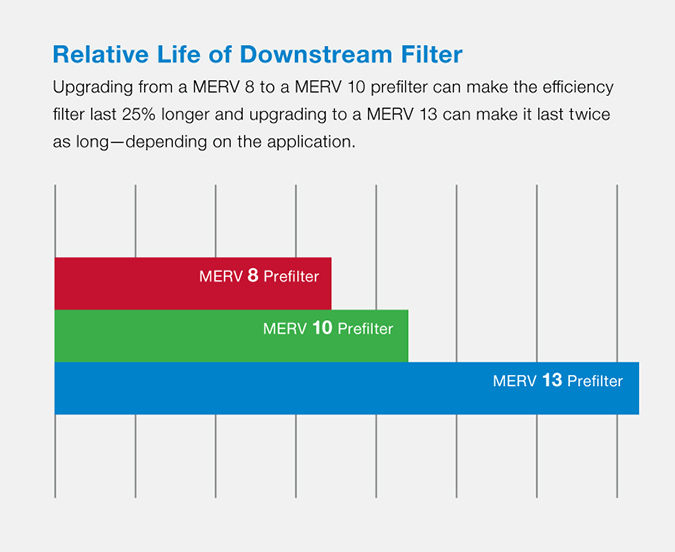

Recognizing when a prefilter is required and equally important, when you can go without one, is a key to improving your TCO. Use of a prefilter depends on the results of comparing the costs of energy, lifespan, and MERV of the efficiency filter with that of the prefilter.

Can you afford to ignore TCO?

Hidden costs are everywhere and easy to miss. The purchase of any given filter is often driven by the lowest upfront price. This decision can lead to ballooning hidden costs of higher energy consumption and increased maintenance, adding to overall operation costs.

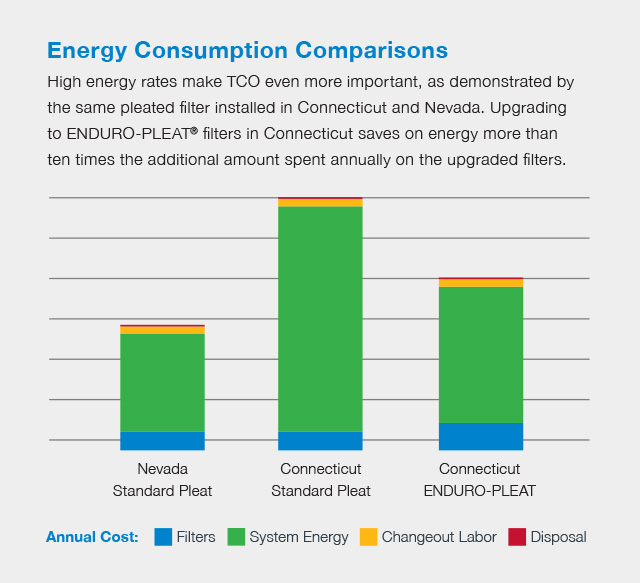

In the United States, geography plays a significant role in the amount of money spent on energy. Combined with ambient condition fluctuations, energy costs alone can be the difference in an optimal-functioning system and one that costs more than it should.

A closer look: energy and geography

Two customers located in different regions of the country using the same filter experienced marked differences in operational costs. This real-world example demonstrates the importance of considering energy costs, particularly in areas where energy consumption is premium-priced. The energy consumption required to push air through filters is the greatest portion of cost associated with HVAC filters.

In Connecticut, energy costs were $0.1721 per kWHr and in Nevada, energy costs were $0.07465 per kWHr. When comparing the annual TCO of 1 standard 24 x 24 pleat, the TCO in Connecticut is double the cost in Nevada, because the annual energy cost is 130% higher. Using a higher-performing TCO pleat high-cost energy regions like Connecticut reduces the energy to 40%.

A comprehensive TCO analysis

A TCO analysis supports pragmatic purchase decisions by including ongoing operational costs. Trustworthy filtration experts help navigate the process, so bottom lines are positively impacted.

Primary cost considerations in a TCO analysis include:

- Filter purchase price

- Installation

- Energy consumption

- Filter lifespan

- Repairs

- Maintenance

- Disposal

In addition to the primary considerations, secondary considerations include long-term costs over the lifespan of your system, depreciation, and other factors such as cashflow, geography and any number of system-specific elements.

Key questions to start your TCO discovery

- Do you know the optimal changeout schedule for your filters?

- Are you able to recognize when a prefilter is required and when it is not?

- Do you know the benefits of a higher MERV prefilter?

- What is the total added cost of a higher MERV filter?

- When was the last time you underwent a complete Air Filter Audit?

- Is your HVAC system and production equipment optimized for TCO?

Getting down to business

HVAC filter experts are available to provide information and guidance to help navigate critical purchasing and system maintenance decisions. It is imperative to work with reliable and trustworthy HVAC technicians who provide sound information based on best practice methodologies. As you establish a relationship with a professional HVAC team, they will assess your system and suggest a changeout schedule matched to your system and application conditions.

Recognizing when a prefilter is required and equally important, when you can go without one, is a key to improving your TCO. Use of a prefilter depends on the results of comparing the costs of energy, lifespan, and MERV of the efficiency filter with that of the prefilter. The higher the MERV of a prefilter the longer the efficiency filter will last before requiring a changeout. HVAC experts help determine the best steps in selecting the MERV of your prefilter. Sometimes a simple step from a MERV 8 to a MERV 10 can have a significant impact on improving downstream filter life and TCO.

In some scenarios, there is a large amount of media already incorporated into the design of the efficiency filter, which substantially increases the dust-holding capacity and, therefore, a prefilter isn’t necessarily required.

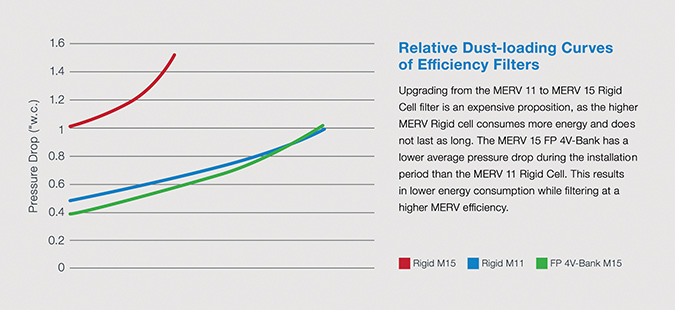

Often, there are questions regarding the higher costs of MERV filters. When evaluating different filters, the balance between pressure drops and dust-loading capacities must be considered, assuming the filters are similarly priced. The savings in energy consumption over time is generally more substantial than the upfront cost of a “better filter.” It is important to remember that just because a filter has a higher MERV does not necessarily mean it has a better or worse TCO, many variables need to be considered, including the filter format.

Air Filter Audits need to be conducted every few years. As systems age, energy costs fluctuate and filter technology changes. Ensuring that your system is optimized requires that you maintain a consistent regimen of audits and confirming that your TCO is as low as possible.

How do I know if I have the right solution after installation?

TCO optimization is a cyclical process and includes analyzing, installing and measuring to ensure the best solution is in place. However, if your expectations do not meet the actual results, there are steps you can take. For example, if in three to six months after installation your TCO is higher than planned, consult with your HVAC expert and technical team. Using precision TCO tools, a quality HVAC technician will reanalyze your operations, reconsider the dirt/dust in the airstream and consider different changeout schedules and filters to help you reach your optimal TCO.

Monetize performance & improve your bottom line

Years of research and development have yielded products that achieve required filtration efficiencies while delivering a lower TCO. The products shown to the right combine innovative technology and precision materials with demonstrated efficiency ratings that help facilities take command of their total costs.

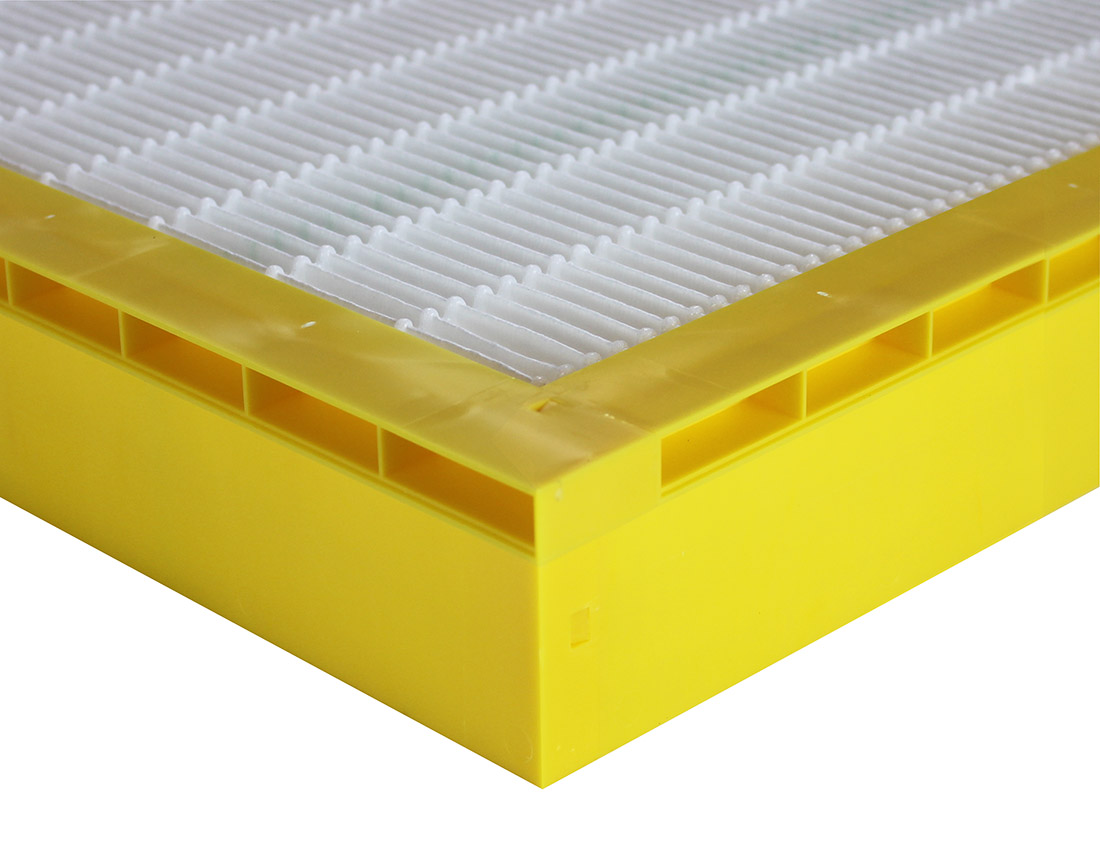

The ENDURO-PLEAT is a tough filter that is designed to save time and money in all applications. It is constructed with stronger components for longer service life and reduces energy consumption thanks to a low-pressure drop and high dust holding capacity.

The Geopleat filter is a compact efficiency filter with a large amount of media. It guarantees a long lifespan and requires less space, while filtering at a high MERV. It saves on shipping and storage costs due to its compact design.

The FP 4V-Bank Minipleat provides efficient media and industry-first design resulting in High Dust Holding Capacity. It is often able to save on energy, filters, and labor by not requiring a prefilter. This filter consumes less energy due to its low pressure drop, saves all the costs associated with a prefilter, and provides the best savings when considering TCO.

The recently launched FP Dual-Pak 4V-Bank Minipleat does the work of two filters in one, like the standard FP. It performs a broad spectrum of gas phase and particulate filtration with a much lower pressure drop when compared to separate MERV 15 and gas-phase filters. This reduces TCO for applications that need this level of filtration, while becoming affordable to applications that don’t need it, but could benefit from it.

There are circumstances when a filtration solution may have the lowest upfront price, yet most applications save money with higher-performing, albeit more expensive filters. Ultimately, products and services that deliver overall value through lower average pressure drop and longer lifespan are the keys to monetizing your HVAC performance and will help lower TCO.