If it can be hard to explain the key role of filtration to the general public, making people aware of the link between filtration, energy consumption and carbon emissions can seem downright impossible.

But make no mistake: Energy is critical to filtration, and it’s only going to become more so in the coming years. Energy is easily the main cost of filtration – and the burning of fossil fuels to create that energy is by far the main contributor to global warming.

With the help of some impressive new technologies and capabilities – and also through closer collaboration – the filtration industry can substantially reduce the energy consumption

required for effective filtration. Doing so not only will create greater value for the filtration industry, but it will also make a very significant contribution to the world.

The Big Picture

Globally, energy consumption, whether in buildings, transportation or industry, is responsible for most of the world’s greenhouse gas emissions.

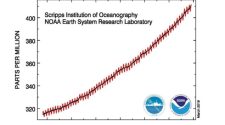

According to OurWorldinData.org, more than 73% of greenhouse gas emissions in 2016 were tied to energy consumption. For comparison, agriculture and forestry contributed about 18%, industry just above 5% and landfills and wastewater about 3%. And carbon emissions have done nothing but rise significantly over the past century.

The Paris Accord lays out ambitious greenhouse gas reduction targets between now and 2090. Achieving those will take tremendous effort and new technologies and approaches.

And the filtration industry has an important role to play.

Lots of Energy

As those in the industry know, most of the cost of filtration is related to energy. To ensure clean air and liquids takes well-engineered filtration systems and energy. Lots of energy. In most applications, around 60% to 90% of the total life cycle cost of filtration is the energy needed to push the air or liquid through a filter. This is not well known to the general public or even among many buyers of filters and filtration systems.

What’s more, filtration uses a significant portion of all the energy consumed around the world today. It is estimated that filtration is responsible for between 2% and 4% of total world energy consumption; some estimates are much higher.

Whatever the percentage, cutting energy use in the realm of filtration will help contribute to the overall reduction of greenhouse gases and reaching the Paris Accord targets. Reducing energy use in filtration by 50% would be equivalent to delivering about 2% of the carbon reductions the Paris Accord calls for by 2030. That’s from an industry that is a tiny fraction (less than .05%) of global GNP. Clearly, the filtration industry has an outsized opportunity to make a positive impact on the world.

There’s also a business case for improving efficiency and cutting emissions. Although it will take time to realize a 50% improvement in filtration energy efficiency, together the filtration industry can enable economic value worth well over $100 billion – far greater than our industry’s annual total revenue.

There is now a greater sense of purpose to the work and the potential for the industry to make a greater contribution to the world.

A Horizon of Advances

Fortunately, the filtration industry has some impressive new technologies and capabilities to help effect change and produce results. These new technologies have the ability to lower the energy used in most filtration processes by around 50% while also lowering total cost, improving health and delivering a

1% reduction in global energy consumption for a healthier planet.

These newer technologies and capabilities include:

- Air quality sensors that are now much better and lower in cost. These make the output of filtration systems visible and measurable in real time, enabling the monitoring of something that was largely invisible in the past. This is driving greater awareness about Indoor Air Quality (IAQ) and will drive increased use of higher-performing, more energy efficient “dynamic” filtration systems.

- Automated control systems and variable speed drives that enable HVAC systems to deliver clean air with improved energy efficiency.

- Advances in filtration media. Using new composites and three-dimensional constructs can reduce the pressure drop of filters by up to 50%. These new materials also enable older filtration systems to be retrofitted with much higher filtration efficiency with minimal or no increase in pressure drop or energy use.

- Improvements in filtration system design, layout and configuration, which improve overall efficiency.

- Energy efficiency classification systems, such as Eurovent, in Europe, which enable straightforward energy efficiency comparisons for filters and HVAC equipment.

- New filtration standards, like those in California through Title 14, or healthy/sustainable building standards such as LEED and WELL, that ensure minimum levels of filtration to improve indoor air quality.

A Greater Contribution

The increasing market needs for health, energy savings and climate sustainability are creating new opportunities for the filtration industry. Higher performing technologies are enabling industry leaders to clearly demonstrate the immense value that filtration can provide, transitioning from what has often been a supporting, seldom-visible role to a central role contributing to human health and the environment.

Along the way, there is an ongoing shift from a focus on upfront costs and service to a broader focus on lifecycle total cost of ownership, health and energy efficiency. Companies in the industry are moving to more of a systems approach, delivering a healthy, energy-efficient environment that is continually measured and verified.

Filtration is increasingly playing a central role in addressing existential societal needs of human health, energy efficiency and climate sustainability. The value creation is substantial and represents a great opportunity for the filtration industry.

While filtration has long been important, there is now a greater sense of purpose to the work and the potential for the industry to make a greater contribution to the world.

Realizing this potential will drive great change and opportunity for the entire filtration industry.