Nonwovens producer Mogul, recipient of two IDEA Entrepreneur awards, has once again introduced a new product with unique nonwoven properties. The new product, Madaline®, fills the gap in nonwoven fiber technologies by having the strength of a spunbond together with microfilaments with size equal to or smaller than that in meltblown fabrics.

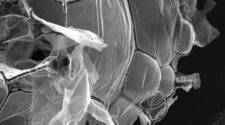

Madaline uses a patented bico technology of polyester (PET) / polyamide (PA) for producing continuous filaments with multiple fiber geometries. The filaments can be extruded in two different filament shapes: “Hybrid Mix” or “Multi-Lobal.” These continuous filaments are subjected to high pressure water jets, which split them into filaments less than 5 microns while also entangling these fibers and consolidating them into a dense web. This process allows Madaline to be made without binders and avoids holes associated with needle-punch products.

The resultant Madaline fabric provides very efficient filtration properties with the strength of a spunbond. The combination of filtration properties and high strength will allow the use of lower weights at equivalent efficiencies, with lower pressure drop, which means reduced energy consumption and improved sustainability.

Additionally, the Madaline process produces mixed fibers, comprising both large and very small fibers throughout the web. Such a mixture of fiber sizes results in filtration properties of longer life and lower pressure drop with equivalent air efficiency compared to structures in which all the very small fibers are in a single layer. Envisaged filtration applications of Madaline are for liquid filtration applications and as a replacement for micro-glass for high end filtration.

Madaline is produced up to 200 gsm at web widths of 3000 mm. The product offers spot-to-spot uniformity for heightened reliability; also its continuous filaments mean reduced fiber migration thereby adding strength and ensuring freedom from lint. Due to microfilaments Madaline breathes well, which makes for good moisture management i.e., absorbing and speed of drying. The strong structure provides a fabric capable of multiple washes. It also exhibits very good thermal insulation, wind resistance and UV protection.

In addition to filtration, Madaline can be made to be very soft and drapable for a wide range of other applications including textile applications (replacing woven and knitted fabrics), clothing, scratch free wipes, etc. Madaline can be finished with processes such as dying, printing and stitching, similar to textile fabrics.

The Madaline process produces a Polyester/Polyamide fiber, which is sometimes also referred to as a polyester/nylon bicomponent fiber.

The raw materials in the Madaline product complies with the requirements of the Commission Regulation (EU) No 10/2011 of 14 January 2011 on plastic materials and articles intended to come into contact with food most recently amended by the Commission Regulation (EU) No 2016/1416 of 24 August 2016.