A2Z Filtration Specialities is a designer and manufacturer of complete customer-centric automation solutions for filter production & assembly. With a dynamic work force comprising of over 50 engineering professionals in designing, manufacturing, and installation, A2Z provides complete turnkey solutions around the globe. The A2Z Design Team uses state-of-the-art Solid Works® 3D design software for the designing and simulation of filter production lines. A2Z’s deep knowledge of filter manufacturing processes and their ability to develop customer specific innovative and efficient lines has resulted in development of fit-to-purpose solutions.

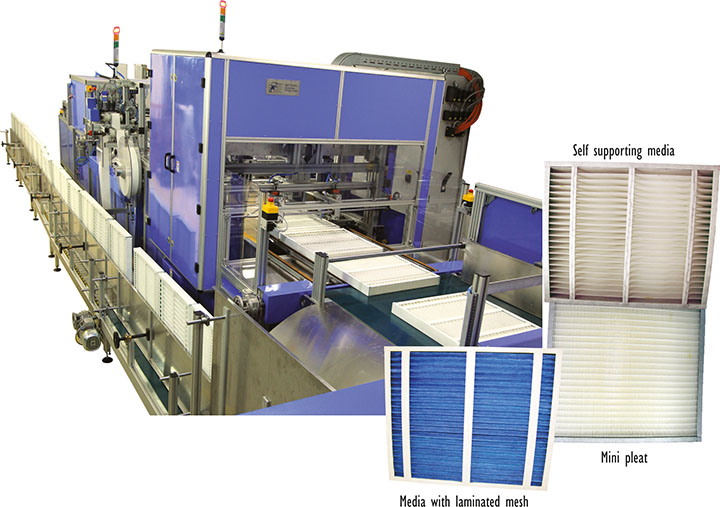

HVAC filter manufacturing – now automated with a minimum human intervention

Starting with the pleating of self-supporting media with A2Z Intelligent Servo Pusher Bar Pleaters or A2Z Star Rotary Pleaters. The inline pitching is done by the A2Z Pleat Pitching System, then conveyed to the A2Z Intelligent Servo Filter Framing System to frame the first and second sides of the Pleated Pack with a hotmelt laminated board. After cutting the pack automatically, based on size or pleat count, the same process is repeated to the third and fourth sides to give complete framed filters. This process requires only one operator based on the options chosen and has a production rate of five to six filters per minute.

Automated HEPA mini pleat – complete assembly lines

After converting rolls of glass fiber and synthetic media into mini pleat packs with foamed or regular hotmelt on A2Z Mini Pleat Blade & Rotary Pleating Lines, the packs are automatically cut to the required size or pleat count, then conveyed to A2Z Intelligent Servo Filter Framing System and framed with hotmelt laminated side banding (I/L/C) configurations and cut to size online. After two sides are banded, the packs are conveyed and the same process is adopted to provide a complete four-sided fully framed filter.

Automated cabin filter lines

These lines are very versatile and can be used to pleat a wide range of cabin filter media ranging from thick activated carbon media to a full spectrum of synthetic media. The line is also compatible with various ribbon media. This offers high production rates of up to 15 filters per minute. Continuous monitoring of product quality, wide range of data capture online, including production/rejection rates/poke yoke, etc. These complete lines are managed by a single operator. The equipment consists of highest quality hot-melt equipment integrated for optimum utilization of hot melt, including for ability to control thickness of hot melt lamination on side bands, and the ability to view the product at each stage of the process. Options to seal multi-layer media to prevent media migration, particularly in activated carbon.

A2Z filtration provides:

- Fit-to-purpose manufacturing, assembly & automation Solutions

- Value prices for quick return on investment

- Ability to Integrate various automation solutions and processes including online quality validation systems

- Globally serviceable lines

- Latest state of the art manufacturing & automation solutions

- IoT & Industry 4.O compliant systems

This content sponsored by A2Z Filtration

Visit us at FILTECH: Hall 8, Stand A9