More than 440 exhibitors will present new technologies and approaches for current and future challenges at FILTECH 2023, which takes place again in Cologne, Germany from February 14-16 next year.

“The innovative power in the field of filtration and separation is strong,” said Suzanne Abetz of the show’s organizing team. “Particularly in air filtration, fine dust values and gases that affect the climate, germs that are harmful to health, and other impacts are increasingly leading to new developments. In solids separation and solid-liquid separation too, there are always new developments striving for maximum efficiency and higher qualities.

“In a dynamic environment, FILTECH 2023 will prove once again that it is the global platform for the filtration industry and adjacent sectors. With 180 lectures planned in the conference we expect a wealth of impulses for research and manufacturing companies in the filtration and separation industry.”

Microfiltration

Center stage at the exhibition will be many new types of filter media for a host of differing end-uses.

In HVAC indoor air filtration, for example, BinNova, based in Rudolstadt, Germany, will showcase its latest Triple Air polycationic microfiltration media for the permanent immobilization of hazardous particles, allergens, bacteria or viruses.

The wetlaid nonwoven media has a permanent polymeric coating that provides an extremely large polycationic surface and the irreversible adsorption of negatively charged particles such as allergens, bacteria and viruses.

It provides added value through the irreversible immobilization of charged particles down to the molecular level and eliminates substances of concerns such as silver, zinc and quaternary ammonium compounds.

Nanofibers

A unique platform with multiple production technologies allows Fibertex Nonwovens, headquartered in Aalborg, Denmark, to provide tailored filtration product concepts for both air and liquid filtration based on needlepunch, spunlace, spunbond, high loft, activated carbon and nanofiber production technologies.

In particular, the company’s proprietary nanofiber production capability allows air filtration products up to HEPA 13 efficiency level which can be used in various applications, including vacuum cleaners, air purifiers, HVAC systems, respirators and cabin air filters. Additional properties such as permanent extra hydro and oleophobicity can be added by plasma treatment.

Activated Carbon

Helsatech, a Mann+Hummel company, is a specialist in designing and producing air filtration media based on activated carbon as well as other adsorbents. Its multifunctional media reliably remove a wide variety of odors and pollutants from air including particles, VOCs, basic gases like ammonia or amines and acid gases like H2S, SO2 and NO2.

Formaldehyde is contained as a binder or preserving agent in many plastics, paints, cloths, floorings and furniture made of flake boards. Since 2015, it has been classified as category 1B which means it can cause cancer in the nasopharyngeal zone when inhaled.

In response, Helsatech has developed a media based on impregnated activated carbons for the enhanced removal of formaldehyde from indoor and cabin air. Within the filtration process, the formaldehyde molecule is bonded irreversibly to the impregnation substance.

The innovative power in the field of filtration and separation is strong. Particularly in air filtration, fine dust values and gases that affect the climate, germs that are harmful to health, and other impacts are increasingly leading to new developments. — Suzanne Abetz

Ionization

FFP-2 level filtration in cabin air filters is meanwhile made possible by a cabin air filter with integrated polarization and an upstream ionizer developed by Hengst, based in Münster, Germany.

Polarization ensures constant filtering performance throughout the entire life of the filter. Cabin air filters normally contain electret media which generally diminish substantially over time, impacting on filter performance, but integrated polarization conserves the charge.

In the ionizer, negatively charged gas molecules charge the contained particles and some in turn form agglomerates. Both single, charged particles and agglomerates of multiple particles substantially improve filter efficiency. The ionizer developed by Hengst achieves uniform charging in a very compact space.

The combined effects of ionization and polarization result in high long-term particle filtering with low power consumption of 2.5 – 10 watts.

Lyocell

Fine fibers known to be advantageous in the formulation of high filtration efficiency media for small particle capture and Austria’s Lenzing is now supplying Lyocell fibrillated fibers for direct incorporation into filter media formulations. This has a positive impact on pore structure, permeability, filtration performance, mechanical properties, chemical resistance and formation.

Commercial applications for Lenzing Lyocell fibrillated fibers in filter media range from lightweight beverage filter papers, through pleatable media for industrial and automotive filters, to heavyweight depth filter sheets.

The fibers are produced from wood using a low environmental impact manufacturing process. They are also fully biodegradable, providing a competitive advantage in markets which increasingly concerned with both performance efficiency and sustainability.

Gradient Structures

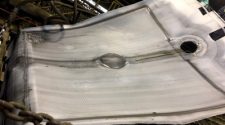

Haver & Boecker is a specialist in woven wire mesh media for solid-liquid separation applications.

In cooperation with the Institute of Mechanical Process Engineering in Stuttgart (IMVT) it has recently investigated and evaluated different offline measurement techniques and particle systems and their influence on the result of the load-dependent fractional separation efficiency (FAG) and the dirt hold capacity of its special media. By means of a specifically selected gradient structure and layer orientation, the load-dependent fractional separation efficiency as well as the dirt holding capacity can be favorably influenced. This has positive effects on the service life and efficiency of both sintered and unsintered multi-layered metal wire mesh combinations.

Benefits for use in filter components include a reduction of blocking tendency and pressure loss, improved separation efficiency and dirt hold capacity and optimized throughput characteristics.

Unique Combination

In addition to new filter media and membranes, FILTECH 2023 will also showcase the latest advances in filter cartridges, elements, housings and modules, as well as technology for processes such as nanofiber electrospinning, coating and pleating. A further emphasis will be on digital design and an extensive range of testing equipment covering all facets of filter production will be demonstrated at the exhibition.

“The combination of congress and trade fair makes Filtech unique,” concludes Suzanne Abetz. “Visitors have the opportunity to experience the latest products and services from exhibitors live and can find out about current trends in research and development in the congress area. For companies from India, Japan, South Korea, Turkey and the USA we have also now established country pavilions to boost participation.”