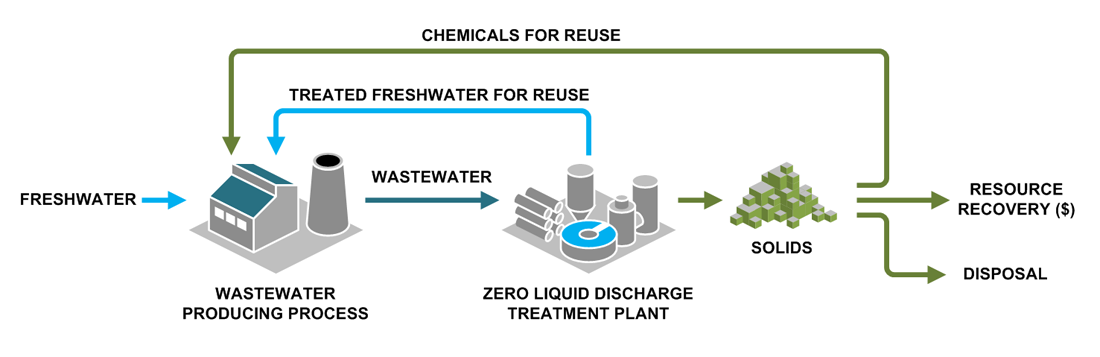

Zero liquid discharge (ZLD) is a filtration process that is gaining prominence as freshwater resources globally continue to decline and environmental regulations for wastewater discharge grow more stringent. At a fundamental level, ZLD technology employs a combination of pretreatment and evaporation to crystalize solids in effluent and produce water for reuse. Once the solids are crystalized, they can be removed and dewatered with a filter press or centrifuge, with the water vapor being condensed and returned to the process or reused in some other way.

In a ZLD system, feed wastewater is typically pumped from a wastewater pond or tank into a feed tank. In the feed tank, the pH is adjusted for deaeration and decarbonation. The wastewater is then processed through a heat exchanger where its temperature is raised to near its boiling point. The heated brine is then pumped to a dearator, where noncondensable gases such as carbon dioxide and oxygen are removed from the brine. The brine then moves to the brine evaporator sump, where the brine from the deaerator mixes with a larger volume of brine. Brine is transferred from the sump to the flood box. It is circulated into the heat transfer tubes where a portion of the brine evaporates and produces steam. A process of recirculation generates water vapor, which is compressed and condensed to produce water distillant, which can be reused once cooled. Concentrated brine then moves to the brine crystallizer. The brine is heated to above its boiling point to facilitate the crystallization process. The heating also causes flashing, which produces water vapor. This evaporated water is condensed and is available for reuse. The crystallized brine then moves to a filter press or centrifuge, where it is further processed and can be, in some cases, repurposed.

Traditionally, ZLD systems have been challenged by their high energy requirement, particularly during the concentration and crystallization stages. However, as the cost of wastewater discharge rises in the face of stricter environmental regulations and ZLD technology becomes more energy efficient, adoption of this technology figures to rise. The market for ZLD technology is expected to reach $9 billion by 2025, with Europe leading the industry, as it has industrially strong countries that face water shortages and are compelled to invest in such technologies by stringent regulatory oversight for wastewater discharge.

Additional Material:

- “Zero Liquid Discharge – maximum recovery and why it finally makes sense,” Global Water Intelligence, https://www.globalwaterintel.com/sponsored-content/zero-liquid-discharge-maximum-recovery-and-why-it-finally-makes-sense-magna-imperio-systems.

- “Zero Liquid Discharge Technology,” SUEZ – Water Technologies & Solutions, https://www.youtube.com/watch?v=aQsK9VK6L5k.

- “Zero Liquid Discharge Mine Water Treatment Plant | Walking Tour,” Saltworks Technologies, https://www.youtube.com/watch?v=_ycSaCAmr0s.

- “Industrial Wastewater Treatment and Zero Liquid Discharge,” Centre for Water Research, Department of Civil and Environmental Engineering, National University of Singapore, https://slideplayer.com/slide/3497515/.

- “Zero Liquid Discharge Systems Market Size By Product,” Global Market Insights, https://www.gminsights.com/industry-analysis/zero-liquid-discharge-systems-market.