A successful air pollution reduction scheme instigated by filtration specialist Mann+Hummel in Germany is set to be replicated at “hot-spots” around the world.

As the home of both Mercedes and Porsche, Stuttgart owes its status as Germany’s richest city to the automotive industry, but in January 2019, a first partial car ban was imposed, effectively preventing any diesel vehicle over ten years old from entering the city of 630,000 people.

For a number of years, a rising protest movement had drawn attention to the city’s status as the most polluted city in the country and called for action. A measuring station installed in 2017 at the notorious Neckartor road junction – which is used by up to 80,000 cars each day – repeatedly exceeded one of the three limit values for fine dust emissions of particulate matter (PM), and specifically nitrogen dioxide (NO2)

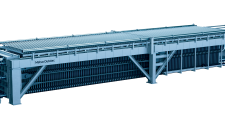

Mann+Hummel, however, believed it had the solution, and in a pilot project at the end of 2018, installed 23 of its Filter Cube filter columns at the junction.

Fine dust capture

The Filter Cubes are designed to trap over 80% of the fine dust and NO2 sucked into them and are based on a combination of a highly effective filter layer for fine dust particles and a special activated carbon layer. Due to its large inner surface, the highly porous activated carbon is able to absorb nitrogen dioxide very efficiently and the use of a combined filter medium enables a particularly high air throughput to purify the air, with very low energy consumption. The pollutants are retained using a number of different processes – physical adsorption, chemical binding and catalytic reduction.

“In the best-case scenario, the Filter Cubes have proved to effectively reduce PM values by 40%, although they are affected by weather conditions and performance varies,” says Jan-Eric Raschke, director of the company’s new Public Air Solutions business. “This, however, is sufficient to get the emissions below the specified limit for NO2 of 40 micrograms per cubic meter on average throughout the year and we now have fifty Filter Cube columns operating at three sites in Stuttgart and three further projects in Ludwigsburg operational.”

Looking at the bigger picture, the economic benefits are substantial, with cities across Germany considering similar bans on older diesel vehicles and Stuttgart even looking at imposing bans on those not measuring up to the Euro V emissions standard, which could apply to vehicles produced right up to 2014.

In a city the size of Stuttgart, this would potentially impact around 50,000 car owners at an estimated cost of around €150 million, making the Filter Cube technology a very valid alternative to keeping emissions below the specified limit.

Electric portfolio

Further developments for reducing emissions are to be found in Mann+Hummel’s rapidly-expanding portfolio of filtration innovations for electric vehicles, such as the brake dust particle filter, which represents an entirely new filtration application for nonwoven media and substantially reduces the particulates which are created during braking.

Braking in city traffic creates significantly more dust than exhaust emissions, the company points out, with every braking action generating it through friction on the disc and pads. This mainly comprises particulates, more than 90% of which are ultra-fine and as a consequence harmful to both health and the environment.

The brake dust particle filter has been extensively tested in Germany in Mann+Hummel’s special ‘fine dust eater’ fleet of vehicles, in close-to real driving conditions. It has proved capable of considerably reducing particulate emissions. The filter can be adapted to existing installation space in the area of the brake disc and is suitable for use with all types of drive, ranging from electric vehicles to hybrids conventional petrol and diesel cars.

At the source

The robust housing of the filter fitted close to the brake caliper allows it to prevent emissions directly at the source of fine dust to the ambient air, in particular in city traffic, which is characterized by frequent braking processes. The synthetic nonwoven filter media is resistant to temperature and corrosion, and the company is also working on hardier versions made from both glass fibers and stainless steel fibers.

The retention of the fine dust directly at the place where it is created prevents the soiling of alloy rims, and to a large extent, the tedious removal of entrenched brake dust – something appreciated by many car drivers.

In addition to use in cars, the filter can also be used in commercial vehicles and in railway applications, where a large amount of harmful fine dust is produced due to the high weight and the long braking distance and frequent braking of rolling stock in semi-enclosed spaces, such as railway stations.

Drive axle

Also recently introduced is the Multigrade eM-CO nonwoven filter media for use in the e-axle, which combines the electric motor, gearbox and power electronics in the latest electric vehicles.

The highly integrated e-axle saves installation space, components and wiring due to being integrated with the drive axle to achieve up to 20% less weight and improve efficiency by between 5-10%.

Because the e-axle’s drive components are integrated, a common oil circuit is sufficient for cooling and lubrication, but there is a drawback – mechanical and electronic components are exposed to oil and metal particles and chips from the transmission which can penetrate the power electronics and electric motor and cause serious damage.

As a result, these particles need to be efficiently removed by a filter integrated on the pump suction side directly in the oil sump to protect the system from the pump to the return flow to the sump.

The new Multigrade eM-CO filter media in this filter is free of glass fibers and has a high chemical resistance and considerably lower differential pressure in comparison to conventional gearbox oil filters fitted on the suction side.

The media comprises consistent filter layers without uncontrolled artificial media bypass – something which is required for conventional products due to their high loss of differential pressure. The use of a depth filter media enables the secure entrapment of the separated particles in the 3D fiber matrix to prevent the reintroduction of particles into the system – a danger which is common with conventional systems. The oil supply can also be permanently ensured without use of an uncontrolled filter bypass, which increases the system’s reliability.

Advanced pleating

The Multigrade eM-CO filter media requires less space due to advanced pleating, which increases dust holding capacity by a factor of almost six. As a result, an installation space of just 20mm is sufficient.

The pleated solution also results in a significant decrease – 75% lower – in the differential pressure. This provided a greater degree of freedom for higher filter fineness or a larger pump to be specified. The filter media always retains its shape and performance, even when exposed to cold or high differential pressure. Stability is ensured by a drainage grid or adhesive lines, which maintain the ideal gap between the pleats.

Worldwide attention

All of these developments are contributing to cleaner driving and reduced emissions for improved air quality, but the initial Filter Cube projects in Germany have in particular, gained worldwide attention.

Stuttgart as a city, and Germany as a country, are far from being the most polluted places on the planet of course, and the technology can be effective anywhere that emissions really peak.

“We now have 15 projects planned globally in some of the most polluted cities, including Bangalore, Delhi and Shanghai, as well as others in Japan, Singapore and South Korea,” Jan-Eric Raschke concludes. “By using several filter cubes at the hot-spots, an area-wide effect is achieved on site and comparatively little installation space is required.”