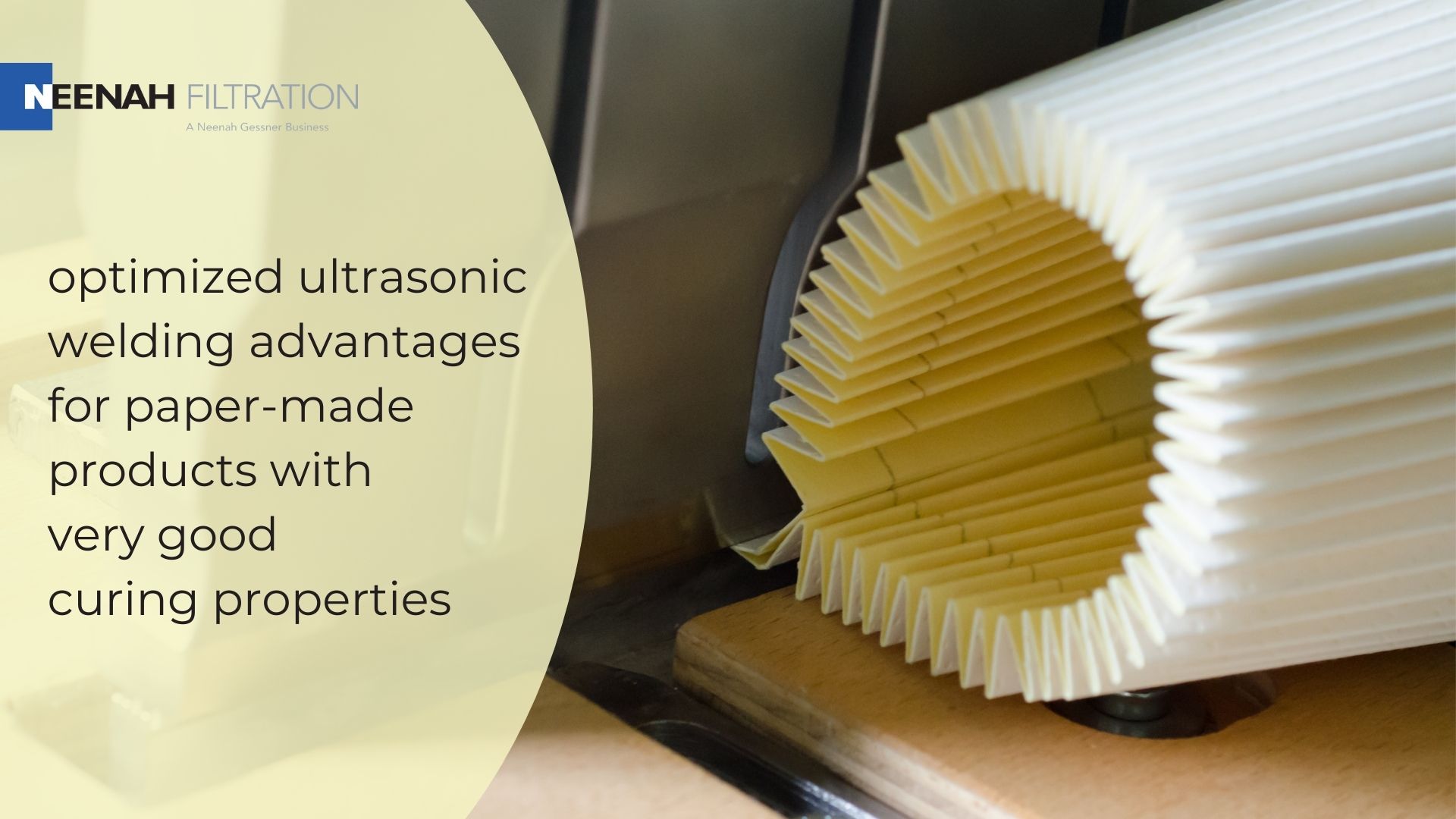

Neenah Filtration has developed a new asymmetric saturation process for optimized ultrasonic welding and curing properties for paper-made products, such as filters.

For converters of paper-made products with an ultrasonic welding machine, Neenah Filtration has developed a material that supports the advantages of these machineries. The asymmetric saturation technology by Neenah Filtration provides a superior converting for filter manufacturers of paper-processing industries to combine paper by an ultrasonic welding process on the paper side without any additional glues or adhesives.

With an ultrasonic welding technology time can be saved, as it is faster than any other welding methods. Another advantage is the saving of production costs, as there are no glue or other adhesives needed. The seals are clean and tight and the result is a high-quality bond.

Neenah Filtration guarantees the necessary requirements for a good filter medium by means of asymmetrical saturation. For example, the company’s GESSNER media are saturated with a resin, phenolic-based and fast-curing, to ensure long-life oil filter element.