HIFYBER is part of the Turkish holding company Abalioglu, which has 2,500 employees with $1.3 billion USD in turnover, operating on four continents. We are experienced in production of polymeric nanofiber-based filter media for various filtration applications on a mass scale. Our innovative nanofiber production technology represents a major breakthrough in air and liquid filtration by providing an extremely low pressure drop, highly durable nanofibers and extended filter life.

At our manufacturing facility in Turkey we can slit master rolls, laminate to produce multilayer materials, corrugate to extend the surface area of the material, and coat with top quality nanofibers on our latest needle-free nanospider lines, all with a dedicated goal to deliver consistency throughout a product portfolio that is world class.

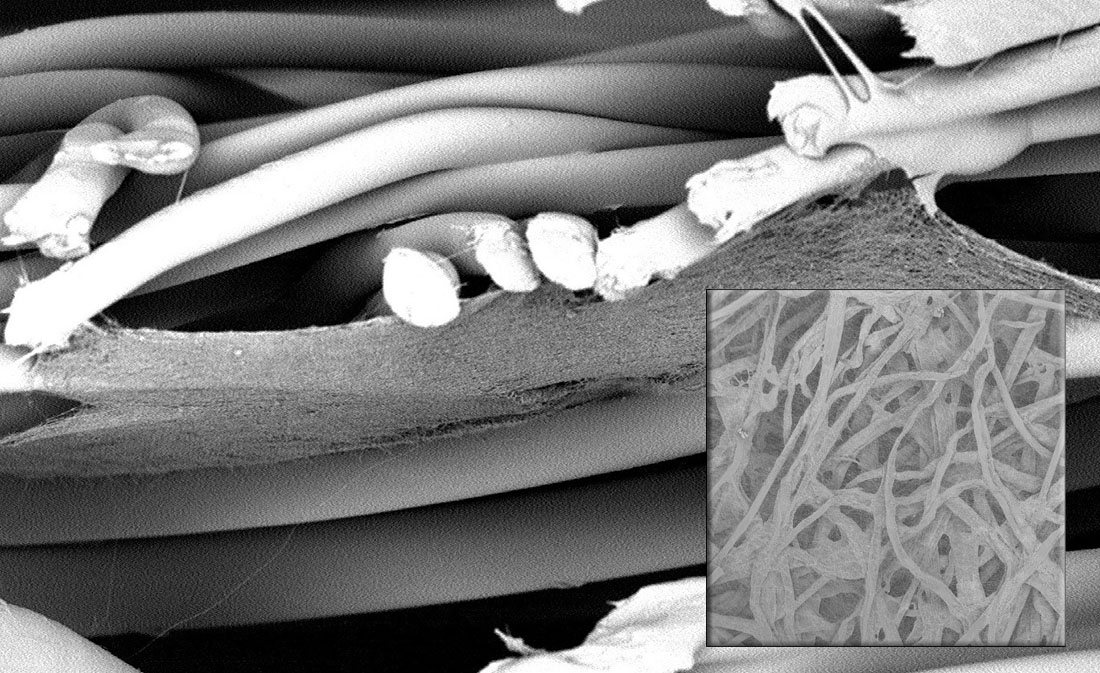

HIFYBER nanofibers are produced with the latest needle-free electrospinning technology giving continuous fibers an average fiber size of 125 nm. Our nanofiber medias have exceptional uniformity and are used worldwide in numerous applications in a variety of markets due to their long life, robust bonding, high mechanical efficiency, and lowest energy consumption, together with a wide array of commercial products. HIFYBER has a unique entrepreneurial approach to in-house capabilities of producing a wide range of custom-made filtration media. HIFYBER manufactures in Turkey and serves directly or through distributors globally.

At our manufacturing facility in Turkey, we can slit master rolls, laminate to produce multilayer materials, corrugate to extend the surface area of the material, and coat with top quality nanofibers on our latest needle-free nanospider lines, all with a dedicated goal to deliver consistency throughout a product portfolio that is world class. We can also perform most of the filtration tests requested and required at our in-house laboratory. Our proprietary nanofibers meet the demands for various filtration applications including HVAC, Facemask, Gas Turbine Air Intake, Industrial Dust Collection, Cabin Air, Engine Intake, and customer-specified composites.

HIFYBER’s filtration efficiencies range from MERV 6 – 16 , F7 – E12 .

Nowadays, air filtration technology plays a crucial role in protecting human health by removing indoor air pollutions while providing an alternative solution for reducing energy usage, operating costs and thus delivering a way to achieve sustainability. Filter medias are that most significant part of filters that does the filtering or separating.

HIFYBER’s high-performance nanofiber media meet ever-increasing demands to reduce energy requirements and CO2 emissions. Likewise, our extraordinary, structured nanofiber media help to decrease the transmission of COVID-19.

- Better Durability ‒ perfect for pulse cleaning

- Improved Dust Release – highly durable nanofibers and extended filter life

- Lower Pressure Drop ‒ extended filter life and longer replacement interval

- Excellent Uniformity – maintaining predictable quality and performance

- Extremely Durable Composite Structure – eliminates the concerns of fiber shedding and suitable to pleat with all pleaters (rotary and blade)

- Extended Surface Area – higher dust-holding capacity

- Outstanding Energy Savings – delivers lowest level of pressure drop and minimizes energy consumption

This content is sponsored by: