In the dynamic and global filtration industry, news and information is breaking on a daily basis. International Filtration News is tracking stories relevant to our industry from air and gas filtration to liquid filtration and the various end-uses for filtration technology. Here we will post news stories relevant to filtration and its downstream applications on an ongoing basis. Please check back for regular updates. If you have news that you feel should be added to this summary report, please email it to Ken Norberg: ken@filtnews.com

Most recent update: March 25, 2024

Valmet to Invest in Filter Fabric Manufacturing in South America

Valmet has decided to invest in filter fabric manufacturing in Belo Horizonte, Brazil, in order to better respond to the growing demand of high-performing filter fabrics in both the mining and pulp and paper industries in South America. The value of the new investment will not be disclosed.

“The investment includes the relocation of the current office and manufacturing facility in Belo Horizonte, new machinery, and improvements in the operations’ energy efficiency and emission reduction. It gives us the necessary assets to further develop sustainable services close to customers,” said Jarkko Syrjälä, Director, Filtration at Valmet.

The new facility will be in operation during the first half of 2025.

Valmet is one of the leading suppliers of filter fabrics and industrial textiles globally. Valmet’s filtration offering covers filter fabrics and felts for the mining and chemical, pulp and paper, and laundry industries, as well as for the variety of dry filtration applications.

American Air Filter Co., Inc. Acquires Northeast Air Solutions, Inc.

American Air Filter Co., Inc. better known as AAF International and a global leader of air filtration solutions for over 100 years, has acquired Northeast Air Solutions, Inc., a leader in providing clean air solutions to New England since 1946.

“This is an exciting announcement for us that we believe will yield important benefits for our customers and our vendors while ensuring the continuity of our business and relationships,” said Bill Couture, Treasurer of Northeast Air Solutions, Inc. “This acquisition symbolizes our intention to deliver more value to our customers while providing them with the same great service they have come to expect,” Couture added. This change in ownership is effective March 18th, 2024.

“Northeast Air Solution’s ‘customer first’ attitude is a great cultural fit for AAF,” said Paul Sennett, AAF International’s Chief Operating Officer. “Adding this team of professionals to our already extensive branch network across the United States and Canada expands access to the world leading filtration technology and technical expertise offered by AAF.”

Metso Celebrates Grand Opening of Service Center in Karratha, Australia

Metso has opened its largest service center globally in Karratha, Western Australia. The center supports the growing demand of customers’ needs, delivering more sustainable, state-of-the-art services. Located in Pilbara, which is a top supplier of iron ore and lithium in the world, the center serves mining and aggregates customers with comprehensive maintenance and repair solutions. The inauguration ceremony was held on March 21, 2024.

“The opening of the new center is an important milestone and further proof of our commitment to accelerate strategic investments in serving customers from pit to port. Strengthening our presence to offer increased productivity, shorter lead times, and environmental advantages, will allow us to take service capabilities and customer experience to the next level,” says Sami Takaluoma, President, Services business area, Metso.

The Karratha Service Center, backed by an investment totaling approximately EUR 32 million (AUD 52 million), spans a 35,000 m² area, including a workshop covering 5,000 m².

Atmus Becomes a Fully Independent Company Following Final Separation from Cummins

Atmus Filtration Technologies Inc. announced its separation from Cummins Inc., marking Atmus’ first day as a fully independent company on March 18, 2024.

“Today we celebrate a new day for Atmus,” said Steph Disher, Chief Executive Officer of Atmus. “As we look at what’s next for Atmus, we have a clear strategy along with a talented and dedicated team that continues to deliver the filtration solutions our customers expect from us. I am excited about all we will achieve as we realize our purpose of creating a better future by protecting what is important.”

As separately announced, Cummins accepted an aggregate of 5,574,051 shares of Cummins common stock in exchange for 67,054,719 shares of Atmus common stock.

Hengst Filtration Opens India Manufacturing Plant

Hengst Filtration, headquartered in Münster, Germany and specializing in filtration and fluid management, announced the opening of a new manufacturing site in Bengaluru (Bangalore), India. More than 90 colleagues, customers, partners and representatives of the press attended the opening ceremony at the new plant.

“India represents a significant growth opportunity for Hengst Filtration. The country’s growing economy and increasing demand for filtration systems across all industries make it an ideal location for our expansion plans,” said Christopher Heine, CEO of Hengst Filtration. “We are confident that our innovative filtration solutions for industry and the environment will be well received in India.”

Hengst said its future plans include producing and selling filtration solutions for the automotive sector, hydraulic applications, medical technology and various branches of industry at the plant, primarily for the Indian market. The site will be headed by Managing Director Sandip Metha, who has 28 years of experience in the automotive and industrial sectors.

NX Filtration and TZW-DVGW Partner for PFAS Removal From Drinking Water

NX Filtration, a global provider of breakthrough filtration technology, has entered a strategic collaboration with TZW-DVGW (Technologiezentrum Wasser, German Water Centre) for a pioneering project aimed at addressing the challenge of PFAS (Per- and Polyfluoroalkyl Substances) removal from drinking water, with minimal energy and chemical dosing.

PFAS, commonly known as “forever chemicals,” are extensively used in various products such as clothing, cosmetics, electronics, and chemical goods. The persistent nature of PFAS in the environment, coupled with known health concerns, has led to growing apprehension. In response to the escalating concerns, Germany implemented a new drinking water regulation in June 2023. This regulation mandates compliance with PFAS-group limits, with specific deadlines set for PFAS20 by January 2026 and PFAS4 by January 2028.

Activated carbon and reverse osmosis have been deliberated as potential solutions for PFAS removal. However, activated carbon is facing increasing scrutiny due to its carbon footprint and limited PFAS sorption capability. Reverse osmosis demands extensive pretreatment and has high energy requirements. In addition, reverse osmosis (RO) typically requires the application of antiscalants and remineralization as post-treatment.

NX Filtration offers an alternative solution with its Hollow Fiber Nanofiltration (HFNF) technology, also referred to as capillary NF or direct nanofiltration (dNF). This method presents an option for water treatment facilities seeking to retain PFAS, as it significantly reduces energy consumption and eliminates the need for pre-treatment and additional treatment chemicals. The efficacy of HFNF in PFAS removal has been substantiated by a comprehensive study conducted by KWR.

Camfil Introduces Gold Series Timer

Camfil Air Pollution Control (APC), manufacturer of industrial dust, fume and mist collection systems for industrial processes, released the Gold Series Timer, its latest dust collection controller. The GST’s innovative design delivers a user-friendly, easily applied pulse-jet cleaning control solution for industrial dust collection systems.

The GST stands out with its pulse output modules, which are seamlessly expandable to accommodate various solenoid valve types and dust collector sizes. Its integrated differential pressure sensor not only enables pulse-on-demand cleaning but also ensures high-pressure alarms for enhanced safety, and extra pulsing modes as necessary.

The GST features an exceptionally clear UV-resistant LCD, conveniently accessible front panel settings and controls, and expandable analogue and digital input/output options. The diagnostic logic embedded in the system provides real-time alerts, ensuring swift response to pulse valve solenoid and diaphragm failures.

The African Membrane Society 4th International Congress

The African Membrane Society will be holding its 4th International Congress (AMSIC-4) in Addis Ababa, Ethiopia, the Headquarters for the African Union and Economic commission for Africa (ECA), November 5-8, 2024.

“Sustainable Innovation in Membrane Filtration Science and Technologies for Circular Economy” is thge theme for the conference. This gathering will be a great opportunity to examine how scientific research and technology can influence the emergence of sustainable development practices in Africa and across the globe.

With Africa’s youthful energy and burgeoning entrepreneurship, the stage is set for unprecedented ideas and innovations to thrive. Many world class experts from the public and private sectors will be presenting their latest research findings and teaching materials in areas such as industrial scale-up of membrane preparation and processes, membrane for water treatment, air filtration and quality control, biotechnological/biomedical applications, waste valorization, seawater desalination, modeling and Artificial Intelligence tools in filtration processes. AMSIC-4 program will include a technical conference, a commercial exhibition, expert panels, tutorials and training/teaching sessions.

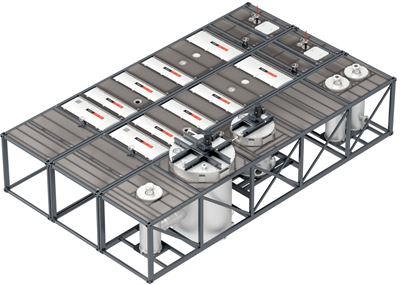

Metso to Deliver Solvent Extraction Technology to China Nickel Project

Metso has been awarded an order to deliver solvent extraction technology for a nickel plant in China.

Metso’s scope of delivery consists of the VSF® X solvent extraction process for the production of a battery-grade nickel sulphate solution. In addition, Metso will deliver multiple polishing filters, a Courier® 6X HX analyser, as well as spare parts and advisory services. Prior to this order, Metso conducted the concept study and process test for the project. Basic engineering for the project is ongoing.

The modular Metso VSF (Vertical Smooth Flow) X plants offer lower lifetime costs, significantly shorter lead times, and sustainable Planet Positive life-cycle technology built on decades of experience in solvent extraction. Metso’s offering includes optimised solutions, complete plants and services through leaching, solvent extraction, and electrowinning technologies.

Sogefi to Sell Filtration Unit

Italy’s Sogefi Group said it has entered into an agreement to sell its filtration business unit for an enterprise value of 374 million euros ($404.93 million) to U.S. private equity fund Pacific Avenue Capital Partners.

The Milan-based firm, which develops and produces air and cooling systems, suspension components as well as filtration systems, said that following the closing of the transaction, the filtration unit will operate under the name Purflux Group. The sale is subject to obtaining clearance from antitrust authorities. The closing of the sale is expected to occur within six months of the deal announcement.

Sogefi further added that at least 50% of the proceeds from the sale, estimated to be around 330 million euros, will be used to reduce the company’s debt, which stands at 266.1 million euro as of Dec. 31, 2023.

Sogefi also reported its full-year earnings on Friday, with revenues of 1.6 billion euros, compared to 1.5 billion euros in 2022, and a proposed dividend of 0.2 euro per share.

Camfil Opens Expanded Plant in Malaysia

Swedish company Camfil recently inaugurated its expanded manufacturing plant in Batu Gajah, Malaysia.

The new plant features diversified production lines, such as molecular filters, turbomachinery and HEPA/ULPA filters. The facility includes a new showroom and an auditorium specifically designed to facilitate customer visits, product showcases, product launches, training and industry events. The plant also incorporates advanced laboratories dedicated to research and development.

The Swedish ambassador in Malaysia, Dr Joachim Bergström, was guest of honour at the grand opening of the expanded plant.

“R&D and innovation are Swedish specialties,” said Dr Bergström. “Locating R&D here in Malaysia allows for the transmittance of knowledge and best practice, tapping into a new pool of talent and creativity.”

Alan O’Connell, Camfil APAC president, said: “The opening of the new plant is a significant milestone for Camfil in the APAC region. It strengthens our ability to meet the growing demand for air filtration solutions while upholding our commitment to environmental responsibility.”

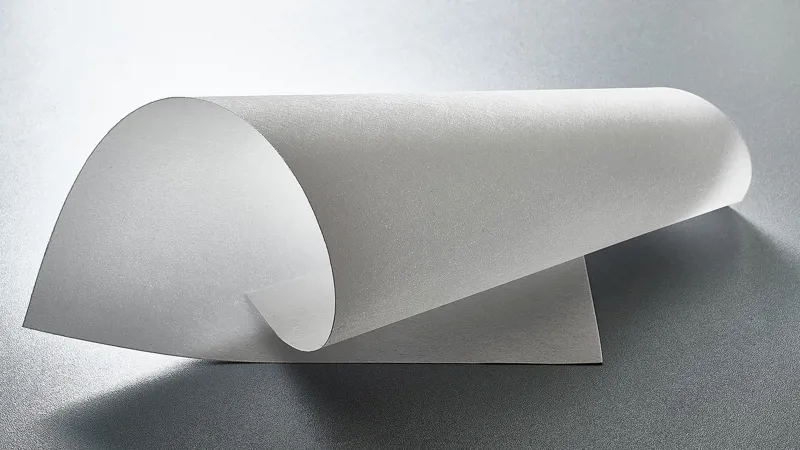

Freudenberg Launches Fully Synthetic Wetlaid Nonwovens for Filtration

Freudenberg Performance Materials unveiled a new 100 percent synthetic wetlaid nonwoven product line made in Germany. The new materials can be manufactured from various types of polymer-based fibers, including ultra-fine micro-fibers. These unique wetlaid materials from Freudenberg are designed for use in filtration applications as well as other industrial applications. This product line rounds off the wide range of wetlaid nonwoven capabilities from the leading manufacturer of high-performance materials.

Customers in the filtration business can use Freudenberg’s new fully synthetic wetlaid nonwovens in both liquid and air filtration. Applications include reverse osmosis membrane support, support for nanofibers or PTFE membranes as well as oil filtration media. The new materials are suited to use in the building & construction industry or the composites industry.