By deploying standardized processes and state-of-the-art single-use technologies, filtration, separation and purification leader Pall Corporation, headquartered in Port Washington, New York, designed the mass manufacturing process for the Oxford/AstraZeneca COVID-19 vaccine in a record-breaking eight weeks – something that would previously have taken years.

In order to rapidly bring the vaccine to market, the University of Oxford’s Jenner Institute brought together the UK Coronavirus vaccine consortium team, which included leaders from numerous academic and industry organizations.

In addition to Pall, the team included the University of Oxford Clinical Biomanufacturing Facility (CBF), the Vaccines Manufacturing and Innovation Centre (VMIC), Advent, Cobra Biologics, Halix BV, Oxford Biomedica and manufacturer AstraZeneca.

Usually, the manufacturing of medicines and vaccines increases as they proceed through clinical development to regulatory approval, according to AstraZeneca. Urgent and immediate need during the pandemic, however, led to scientific, clinical and production teams working in parallel to be most efficient.

Embedded safety

“The safety and high quality of a medicine or vaccine is absolutely paramount,” said Darrin Cowley head of development quality, biologics, at AstraZeneca. “That is why safety and quality control are embedded throughout the production process. More than 60 tests are carried out during the making of every batch of vaccine. We employed the same rigor we apply to every product we make, carrying out tests and checks quickly and in parallel to ensure we could deliver the vaccine at pace and in the vast quantities needed.”

AstraZeneca aims to deliver up to three billion doses of the vaccine across the globe by the end of 2021, which will be just 18 months after the company first partnered with the University of Oxford to develop and manufacture it.

Viral vector

There are many different types of vaccine platforms, each with different production and manufacturing processes.

The Oxford-AstraZeneca Covid-19 vaccine uses a chimpanzee common cold viral vector known as ChAdOx1, which delivers the code that allows human cells to make the SARS-CoV-2 spike protein.

For viral vector vaccines, the vaccine is grown in cells that act like ‘mini-factories’ to create or ‘culture’ the vaccine quickly, using bioreactors – specially designed containers that can hold a large volume of these cells. When grown to the right concentration, a substance to break open these cells allows the vaccine (drug substance) to be released for further production.

In the production and manufacture of such viral vector vaccines, once the required concentration of vaccine has been grown and extracted from the cells to achieve a large volume of pure vaccine, a series of key steps take place – filtration, membrane chromatography, and ultrafiltration.

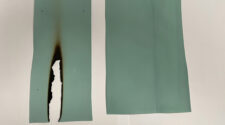

The first filtration steps remove cell debris, and a further series of filtration processes improves the yield and clarity of the vaccine product. Normal flow filtration (NFF) is used, passing the culture through a series of membranes containing varying pore sizes that filter out different sized cell debris and waste products. At this stage, some of the sample can also be removed to create another batch of vector vaccine working stock.

Membrane chromatography then allows the vaccine to bind to a surface to ensure only the product that is needed is left.

Ultrafiltration re-buffers the viral vector vaccine into its final formulation by controlling how acidic or alkaline it is.

Danaher

Two of the biggest acquisitions in the filtration industry in recent years were those by Danaher Corporation, of Pall Corporation for $13.8 billion, completed in August 2015, and of the Biopharma business of General Electric (GE) for $21 billion, completed in March 2020, and now renamed Cytiva.

Danaher entered the filtration, separation and purification business via the acquisition of Pall, and a key driver for it was Pall’s leading position in technology and filter media for bioprocessing.

Of Pall’s sales, around 60% were generated by consumables at the time of its acquisition – principally filters made with the company’s proprietary branded filter media based on membranes, as well as meltblown and wetlaid nonwovens and metal products. The remaining 40% of sales were generated by larger capital goods, typically including proprietary filtration systems and associated hardware.

Expansion plans

In April this year Pall announced that in continuing to increase its capacity to meet industry demands driven by COVID-19, it would make a series of expansions at existing sites and open a new manufacturing facility in Spartanburg County, South Carolina.

“Demand for single-use technology has increased rapidly in recent years,” said Joseph Repp, president of Pall Life Sciences. “With the global need for mass manufacturing of COVID-19 vaccines, there has been even more pressure on the existing supply chain. This global capacity expansion will ensure critical products are manufactured and delivered to our customers, so people around the world have access to life-saving vaccines and genes therapies. Pharmaceutical companies around the world have consequently recognized the urgent need to rapidly scale up the raw materials and critical products required for the mass production of new vaccines.”

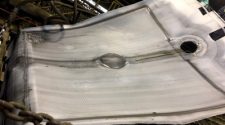

Pall’s new facility in Duncan, South Carolina, will focus primarily on single-use technology, such as the Allegro single-use platform.

Acquisitions

So far in 2021, Pall and its sister company Cytiva have collectively made five strategic acquisitions, and at the end of July announced a further $1.5 billion, two-year investment plan to meet the growing demand for biotechnology solutions.

By opening new sites in the U.S. and U.K. and expanding manufacturing capacity at 13 existing sites, the companies plan to hire 2,000 additional full-time associates over the next two years. This is in addition to Cytiva’s continuing capacity investments which are estimated at $500 million through 2022.

“Our customers tell us they need access to manufacturing agility, a robust global supply chain and more regional options,” said Danaher group executive Emmanuel Ligner. “These investments further fuel our expansion program so we can rapidly meet the current and future needs of our customers and ultimately, their patients.

“We envisage a world in which access to life-changing therapies transforms human health. Our investments and acquisitions are about building capacity and the therapeutic development workflow to advance and accelerate the work of our customers.”

The new capacity expansions will increase the manufacture of the key products used by Cytiva and Pall Corporation to make biologic medicines and include:

- $600+ million in chromatography resins – filter media for analyzing or purifying biomolecules – establishing a new manufacturing site in the U.S.

- • $400+ million in cell culture media – in liquid or powder form this is used to grow and cultivate cells before they are purified – by expanding operations in the U.S., U.K., and Austria.

- • $300+ million in single-use technologies – including bioreactor bags for growing cells used to make personalized medicines and syringe filters for scientific research – by expanding operations in the U.S. and the U.K., as well as fitting out a new facility in Cardiff, Wales.

- • $200+ million USD for continuing expansion work in Cytiva and Pall Corporation’s sites across China and the rest of the Asia-Pacific region, Europe, and the U.S.

Ion-exchange

Chromatography membranes combine ion exchange chemistry with the high flow and processing simplicity of pre-packaged capsules. The high surface area and large pore sizes provide high dynamic binding capacities, especially for large molecules and particles, and are easily incorporated into a process for the removal of impurities or for the purification of select molecules (coagulation factors) or viral vectors (AAV, Lentivirus). The range of scalable formats available allows them to be used in a variety of purification processes, from laboratory to manufacturing scale.

The benefits of membrane chromatography include:

- High binding efficiency due to direct access to the binding groups, even at high flow rates.

- Speed – high flow rates enable the processing of large volumes. As an example, Pall’s Mustang capsules typically operate at a flow rate of 10 membrane volumes (MV) per minute, which equates to 50 L per minute for the largest capsule format. This flowrate is 20 to 50 times faster than conventional chromatography sorbents.

- Scalability and flexibility – a wide range of capsule sizes accommodates various volumes and capacities.

- Ready-to-use – the capsule format eliminates the need for packing and unpacking. If used as part of a single-use manufacturing process, there are no cleaning or cross-contamination issues.

- Lower cost of operation – membrane capsules offer lower operating and capital investment costs than conventional columns that require packing.

- Reduced buffer consumption – the small device footprint requires significantly less buffer.

Spirit

“From one of the most terrible crises humanity has faced in a generation, an incredible spirit of collaboration and remarkable achievements like nothing I’ve seen before in my many years in this industry emerged,” said Jose-Carlos Gutiérrez-Ramos, chief science officer at Danaher. “As we try to predict how our world might change going forward, it’s clear that demand is growing for more vaccines, faster development, and easier access for patients – all of which means we need increased capacity, which has been the biggest challenge we’ve faced during the pandemic.”