Robrecht Hendrikx is the market manager for Venting & Filtration at Nitto Belgium. Robrecht has a master’s in mechanical engineering and has worked in air filter/vent filter applications for over 30 years. In that time, he has developed various HEPA/ULPA air filtration systems in multiple different markets including clean rooms, respiratory equipment, appliances, transportation, and more.

On Feb. 2 2022, Robrecht led an IFN Tech Spotlight Webcast covering challenges and solutions for designing high-performance filters. The following Q&A provides a preview of the material that will be covered during this webinar. To view this IFN Tech Spotlight Webcast, visit bit.ly/ifn-02022022-nittowebinar-ondemand.

Market Manager for Venting & Filtration

Nitto Belgium

IFN: Nitto’s application and technology solutions are quite wide ranging. What can you tell us about Nitto’s technology offerings in general, as well specifically in the filtration space?

Robrecht Hendrikx: Nitto was founded in 1918 to produce electrical insulation materials and has since grown to offer over 13,500 products in diverse markets including filtration, alternative energy, optronics, automotive, and life sciences, among others. Nitto has been developing filtration products for over 40 years starting with capillary and RO liquid membranes, before expanding to air ventilation in 1987. By the late 1990s we were developing high-end ULPA filters for clean rooms. This is still the main segment for our highest class of ULPA filter products.

In the last 10 years, we have seen an increase in demand for HEPA filter media as well in a variety of applications such as vacuum cleaner, air purifier, respirators, cabin filters, etc. This demand has been driven by a need for energy savings, legislation to reduce health risk, and sustainability improvements. As a result, our TEMISH media has found success in a variety of new HEPA filter applications. We are actively developing new products in our labs in Japan to meet evolving industry needs.

IFN: I first learned a bit about Nitto when one of our international correspondents wrote a Technology Spotlight on the TEMISH engineered porous PTFE membrane. How does TEMISH fit into Nitto’s solution set for filtration?

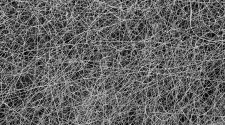

Robrecht Hendrikx: Many people are unaware that there is a PTFE filter media available on the market. TEMISH, an ePTFE media, can solve difficult challenges and meet higher specifications because of its unique properties. As such, it’s become our most popular air filtration product. We manufacture TEMISH in-house using a special stretching process. By doing our own manufacturing, Nitto can cover wide spectrum of requirements from low HEPA’s ( EPA E10) up to the highest ULPA’s(U17). Additional treatments during manufacturing allow us to add more functionalities such as anti-bacteria, flame retardancy, mechanical features (stiffness, thickness), pre-filter layers, etc. Nitto specializes in niche challenges, and TEMISH is a product that exemplifies our unique solutions.

IFN: What are some of the application areas and/or industries where Nitto’s filtration-related technology is particularly strong?

Robrecht Hendrikx: Nitto’s filtration technology has found popularity in high-end applications that require a higher specification level. If the application requires quality and performance, our technology really stands apart from other available filter media. Examples of such applications include clean rooms (requiring low boron, energy savings, longevity) and respiratory equipment (P100 respirators in the US or P3 masks in the EU). The slim profile of our materials can help downsized filters to improve wear comfort. We can also provide oil resistance and high degree of protection against ultra-fine particles such as viruses and asbestos.

IFN: Balancing the tradeoff between collection efficiency and pressure drop in filtration is something most users of filtration technology must confront. How does Nitto’s technology help users overcome this challenge?

Robrecht Hendrikx: In our upcoming webinar, we are going to talk about this challenge. To help users of filtration technology balance these features, we have designed TEMISH to have a very fine fiber structure (nanoscale) which results in a in a high PF factor — the main KPI for a good ratio between efficiency & pressure drop. The correlation between thin fibers and low-pressure drop is also known as the “slip flow effect.”

IFN: Filter size can also be a challenge that users need to address in certain applications. How do you see the challenge of filter size and the drive to reduce the footprint of filtration technology showing itself when you engage with your customers?

Robrecht Hendrikx: This is a very interesting point! More and more we see opportunities for our media where the customer wants to upgrade their filter performance (due to legislation or market trend) but the infrastructure or hardware does not allow more or bigger filters. Application examples include airplanes, HVAC systems for buildings, cars, respirators, etc.

Our media can be fitted to obtain these goals (higher efficiency and/or lower pressure drop) without the need to enlarge the air ducts, fans, filter frames, etc.

IFN: What are some of the interesting areas of filtration technology development and/or applications that show promise for Nitto in the future? Are there any larger trends within filtration that will drive Nitto’s strategy going forward?

Robrecht Hendrikx: Some macro trends that we are seeing include global warming, diesel gate, PM2.5 matter, EU green deal, the COVID pandemic, among others. These issues will have a big impact on how filters are seen in terms of protection levels, energy consumption, sustainability.

IFN: On Feb. 2, you will lead an IFN “Tech Spotlight Webcast” on building high-performance filters. What can attendees expect to learn during your presentation? Without revealing too much, what are some of the highlights the folks who attend this session can look forward to?

Robrecht Hendrikx: We are going to explain some of the challenges that are arriving with global filtration trends and how users can still achieve high-performance filtration while meeting those challenges. I hope we can inspire the audience in their quest for solutions/improvements in the HEPA/ULPA air filtration market.

To view the IFN Tech Spotlight Webcast, “Building High-Performance Filters: Challenges & Solutions,” please visit bit.ly/ifn-02022022-nittowebinar-ondemand.

This content is sponsored by Nitto.