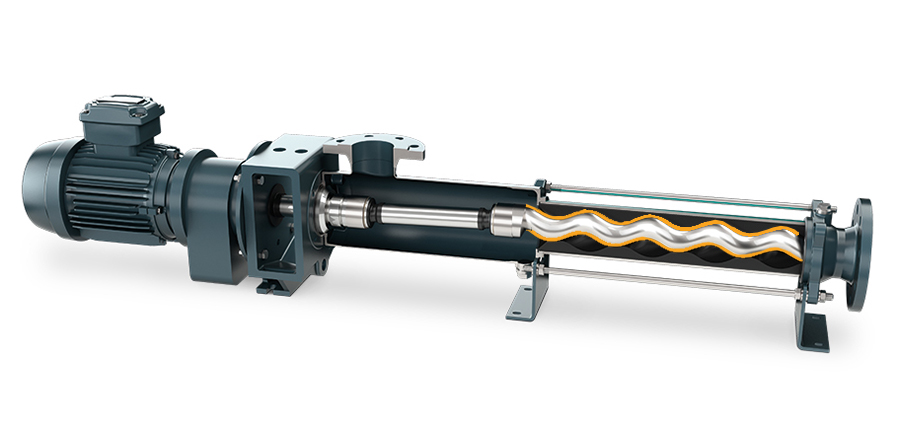

NETZSCH Pumps USA, a leading complex fluid handling solutions provider, announced the launch of N.Durance™ Tungsten Carbide Fusion Coating Technology, a breakthrough surface treatment engineered to maximize the service life and reliability of NEMO® Progressing Cavity Pumps. Developed through extensive research and testing for abrasive and harsh applications, the N.Durance™ coating provides a robust, long-term solution where uptime, durability, and cost efficiency are critical. Designed for highly abrasive and corrosive applications, N.Durance™ delivers a level of protection and performance far beyond traditional coating technologies such as hard chrome plating, HVOF, and plasma spray systems.

The N.Durance™ series, available in Advanced, Pro, and Ultimate versions, enhances rotor durability and significantly extends both rotor and stator lifetimes by leveraging a dense, homogeneous fusion coating with very low porosity. The unrivaled manufacturing process achieves superior hardness, toughness, ductility, and cavitation resistance, minimizing oxidation and decarburization of tungsten carbide particles while improving the cohesiveness of splat layers. This results in better cracking resistance, consistent wear protection, and reliable operation even under extreme conditions. With a hardness of approximately 1,300 Vickers—among the highest in the industry—N.Durance™ delivers exceptional protection against friction and wear from abrasive fluids and solids common in applications for PC Pumps.

With up to seven coating layers available in the Ultimate model, the technology withstands maximum wear, impact, and thermal stress, while the Advanced and Pro versions provide optimized performance for moderately to highly abrasive and corrosive environments. Across the series, users benefit from substantially lower lifecycle costs through reduced downtime, prolonged maintenance intervals, and longer mean time between failures. This is especially valuable for municipal operations, where studies have shown that pumps equipped with N.Durance™ coatings experience significantly longer service life and lower total cost of ownership.

N.Durance™ not only delivers unmatched wear resistance, impermeability to gas and liquids, and improved corrosion protection, but also replaces environmentally harmful hard chrome plating manufacturing processes. Unlike chrome plating, which produces carcinogenic hexavalent chromium, N.Durance™ employs an environmentally friendly manufacturing method that avoids toxic chemicals and hazardous waste. The proprietary fusion process creates a metallurgical bond between the tungsten carbide and the base metal, resulting in a coating that resists flaking or separation caused by corrosion, far surpassing conventional plating or HVOF coatings. The technology is manufactured in-house at NETZSCH’s Exton, PA / USA facility, ensuring consistent quality, controlled processes, and short delivery times. As the only progressing cavity pump manufacturer in the U.S. capable of producing and coating rotors in-house, NETZSCH can machine and N.Durance™-coat rotors in as little as one to two days, even offering same-day shipment when needed. All components are fully compliant with Build America, Buy America (BABA) requirements.

Ideal for industries handling abrasive slurries, corrosive fluids, and erosive environments, N.Durance™ dramatically improves the long-term reliability and efficiency of NEMO® Progressing Cavity Pumps. In municipal wastewater plants, this translates to longer maintenance intervals, reduced downtime, and improved system predictability. When paired with NETZSCH’s smart monitoring solutions, such as NORIUS™, operators can access real-time data on pump performance for predictive maintenance and proactive service planning. By extending the lifespan of core pump components, it reduces total cost of ownership and maximizes uptime for demanding operations across chemical, energy, environmental, and especially municipal water and wastewater markets.