In the dynamic and global filtration industry, news and information is breaking on a daily basis. International Filtration News is tracking stories relevant to our industry from air and gas filtration to liquid filtration and the various end-uses for filtration technology. Here we will post news stories relevant to filtration and its downstream applications on an ongoing basis. Please check back for regular updates. If you have news that you feel should be added to this summary report, please email it to Ken Norberg: ken@filtnews.com

Most recent update: June 30, 2022

Trützschler partners with Texnology

Trützschler Nonwovens & Man-Made Fibers GmbH has embarked on a joint venture with Italian textile machinery manufacturer Texnology S.r.l. to offer complete production lines for needlepunched nonwovens under a new brand called T-SUPREMA.

Web bonding with steel needles represents the largest production process in the drylaid nonwovens segment. The areas of application are predominantly of a technical nature, with the largest applications being durable geotextiles, automotive textiles and filter media.

The high adaptability of the needling and finishing processes as well as the broad material base result in a large number of different end products. Needle-punching is suitable for a wide range of man-made and natural fibers including mineral and high-performance fibers.

Trützschler Nonwovens is contributing years of experience in fiber preparation and web forming to the venture, while Texnology will mainly be responsible for the needlepunching process.

Source: truetzschler.com

Decontaminating heavy metal water using protein from plant waste

Scientists from Nanyang Technological University, Singapore (NTU Singapore), in collaboration with ETH Zurich, Switzerland (ETHZ), have created a membrane made from a waste by-product of vegetable oil manufacturing that can filter out heavy metals from contaminated water.

The research team, led by Professor Ali Miserez from the School of Materials Science & Engineering and the School of Biological Sciences and NTU Visiting Professor Raffaele Mezzenga from the Department of Health Science and Technology at ETHZ, discovered that proteins derived from the by-products of peanut or sunflower oil production can attract heavy metal ions very effectively.

In tests, they showed that this process of attraction, called adsorption, was able to purify contaminated water to a degree that meets international drinking standards.

The researchers’ membrane has the potential to be a cheap, low-power, sustainable, and scalable method to decontaminate heavy metals from water.

Source: Chemical Engineering Journal

Separation technique adjusted for mRNA vaccine boom

A common technique for separating polymers, such as proteins, has been adjusted for analysis of mRNA-lipid nanoparticle (LNP) vaccines. Multidetector Field Flow Fractionation (MD-FFF) has been in use in mRNA research for several years, but it has seen a huge growth of interest for mRNA-LNP manufacturing, according to researchers at SINTEF (Norway), a large European research organization.

SINTEF is using MD-FFF to analyze samples for pharmaceutical clients, according to Jérémie Parot at SINTEF, and the systems they’re using for RNA-LNP analysis are different from traditional MD-FFF. “The technique is well-known for nanoparticles, or proteins, but LNPs are different and fairly fragile, so instrument manufacturers needed to develop a new separation device called frit-inlet channel that has less effect on particles,” he explained.

MD-FFF is a liquid-based separation technique. Compared to dynamic light scattering techniques, MD-FFF gives a high resolution because it physically separates particles into different sized buckets before they are analyzed.

The MD-FFF process involves injecting a stream of liquid into a channel with a membrane at the bottom. The liquid undergoes two separation phases. First, being pushed downwards under pressure towards the membrane, then being allowed to relax and spread out through the channel, which sorts them by “size.”

After the particles have been separated, they can have important features measured using various detectors such as UV/Vis, multi-angle light scattering or by studying their refractive index. Parot says the technique gives a high-resolution analysis while not damaging the fragile LNPs.

Source: genengnews.com

Fully biodegradable cellulose membrane proves effective in oil-water separation

A group of researchers at Shanxi Institute of Coal Chemistry (part of the Chinese Academy of Sciences—CAS) have developed a new and improved method using two different cellulose materials, allowing them to obtain membrane materials for oil-water separation that are “all cellulose” (cellulose with two or more different crystal forms).

Importantly, as they outline in their study results, published in Green Energy & Environment, their membrane is friendly to the environment.

According to Prof. Tiansheng Deng, the paper’s corresponding author, “oil-water separation membrane materials that have been widely used in recent years include vinylidene fluoride (PVDF), polypropylene (PP), polyacrylonitrile (PAN), nylon or their composites. However, these polymers are non-biodegradable and put further pressure on the environment.”

To solve this problem, Prof. Deng and his group chose degradable cellulose derived from plants as a raw material and then bonded it with commercial cellulose filter paper, which is low in price and porous. They found that a large number of nanopores appear in the modified cellulose filter paper, which improve the membrane’s barrier against oil droplets. When their separation membrane comes into contact with water, a cellulose hydrogel is formed that effectively separates oil-water mixture and oil in water emulsion.

Prof. Deng added that “cellulose chains are tightly bonded by a hydrogen bond, with few defects, and the mechanical properties of the material are greatly improved. The high dry and wet mechanical properties of the membrane extend the ways in which it can be applied and help it to remain stable when used in water. We believe this is an important step forward in the treatment of pollution.”

Source: phys.org

KSS Acquires LIONEX Technology

Koch Separation Solutions (KSS) announced the acquisition of LIONEX technology from Chemionex Inc. The acquisition serves as the foundation for the launch of their Li-PRO(TM) process featuring a proprietary global solution for Direct Lithium Extraction (DLE).

The Li-PRO(TM) process is an optimized DLE process configuration combining specialized lithium selective extraction media and leading KSS equipment including robust PURON(R) membrane-based pretreatment, Recoflo(R) packed bed lithium extraction, Recoflo softening, and high-recovery reverse osmosis (RO) concentration operations to generate a purified lithium chloride solution. The solution is geared towards customers seeking an optimized solution to developing lithium battery materials to keep up with the growing demand for lithium batteries, primarily in electric vehicles.

Source: www.kochseparation.com

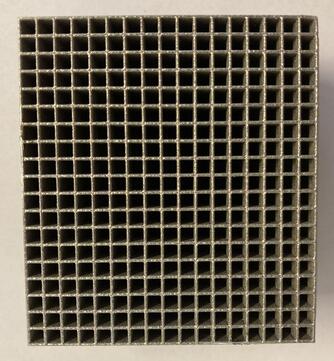

Westinghouse creates and installs industry’s first 3D-printed fuel debris filter for nuclear power plants

Westinghouse installed its StrongHold® AM 3D-printed nuclear fuel debris filters in two Nordic Boiling Water Reactor (BWR) units – Olkiluoto 2 in Finland, and Oskarshamn 3 in Sweden – to further improve the plants’ operational reliability.

Westinghouse created the StrongHold AM filter in close cooperation with plant operators Teollisuuden Voima Oyj (TVO) and OKG. The StrongHold AM filters are fully manufactured through 3D printing techniques and offer enhanced capture features to prevent debris from entering the fuel assembly and potentially damaging the cladding, which could cause unplanned and expensive outages.

“We can now gain important practical experience in the use of 3D-printed metal products which will become an ever more important operational solution going forward. It is important to have a strong network of partners like Westinghouse who deploy additive manufacturing to drive enhanced capability,” said Arttu Knuutila, TVO Fuel Procurement Team Leader.

“As the first 3D-printed fuel debris filter for insertion in a nuclear power plant, the StrongHold AM marks a major milestone in our effort to further improve the BWR fuel reliability by leveraging advances in manufacturing technology,” said Dr. Carina Önneby, Westinghouse Vice President EMEA Fuel Delivery.

Source: www.westinghousenuclear.com

Donaldson adds Purilogics to Life Sciences portfolio

Donaldson Co. Inc. has bought Purilogics LLC, an early-stage biotechnology company that develops membrane chromatography products for the growing biopharmaceutical industry.

Purilogics offers a portfolio of purification tools for a range of biologics, including mRNA, plasmid DNA, viral particles, monoclonal antibodies and proteins. The company’s proprietary formulations and processes create membranes that enable faster and more cost-effective production of increasingly complex biologic drugs.

Founded in 2013 by Jinxiang Zhou, PhD and Scott Husson, PhD, Purilogics is headquartered in Greenville, South Carolina, USA.

Donaldson acquired Purilogics for an initial purchase price of approximately US$20 million as well as milestone-based earnout payments over the next five years. Once commercialized, revenue from Purilogics’ products will be reported within the Donaldson Industrial Filtration Solutions business in the Industrial Products segment.

Source: www.donaldson.com

Filtration Group acquires Whirl-Pak

Filtration Group, an affiliate of Madison Industries, has acquired Whirl-Pak®, a leading provider of sterilized sampling and testing solutions including its line of write-on, stand-up, filter and other specialty single-use sterilized sampling bags and accessories. Whirl-Pak® is globally recognized for best-in-class quality and is routinely specified as the sterilized sampling and testing brand of choice by industry and regulatory standards. Customers worldwide in the food & beverage, pharmaceutical, personal care, water and contract testing end markets trust Whirl-Pak® for their sampling and testing labs.

The addition of Whirl-Pak® will expand Filtration Group’s innovative offerings in food safety, pharmaceuticals and other mission-critical life sciences applications, furthering its mission of making the world safer, healthier and more productive.

Source: www.filtrationgroup.com

A.O. Smith Acquires Water Treatment Solutions Provider Atlantic Filter Corporation

Water technology company A. O. Smith Corporation announced it acquired Atlantic Filter Corporation, a Florida-based water treatment company in an all-cash transaction. Terms of the transaction were not disclosed. Atlantic Filter joins other A. O. Smith acquisitions Aquasana (2016), Hague Quality Water (2017), Water-Right Group (2019) and Master Water Corporation (2021) in the company’s growing North America Water Treatment business.

“The acquisition of Atlantic Filter further expands our capabilities in Florida and beyond. A. O. Smith is committed to growing our water treatment business as part of our strategy to deliver innovative, differentiated solutions that heat and treat water,” said Kevin J. Wheeler, president and chief executive officer.

The third-generation, family-owned company was founded in 1955 and is based in West Palm Beach, Florida. Atlantic Filter Corporation is a manufacturer and dealer of quality water treatment equipment for residential, commercial, institutional and industrial use. Atlantic Filter’s products are sold through their retail dealership located in West Palm Beach.

Source: aosmith.com

Iowa ethanol plant installs Whitefox ICE membrane solution

A Whitefox ICE membrane dehydration system is currently being installed at The Andersons Inc’s ethanol plant in Denison, Iowa, USA.

This is Whitefox’s 11th installation in the US and its fourth installation in Iowa. The installation project is in its last stages of completion and is due to be commissioned in October 2022.

The Whitefox ICE system treats existing recycle streams to free up and debottleneck distillation-dehydration capacity, enabling The Andersons to lower natural gas use, cut carbon emissions, improve plant cooling, and increase potential production capacity depending on the system design.

Source: whitefox.com

INDA promotes Fragnito to president to succeed Rousse, who is retiring in January

The Board of Directors at INDA, Association of the Nonwoven Fabrics Industry, has elevated Tony Fragnito from chief operating officer of INDA to president of INDA, effective May 31.

Fragnito will assume the position currently held by Dave Rousse, who will become president emeritus and provide support and assistance to Fragnito as needed until Rousse fully retires in January 2023.

Fragnito joined INDA November 29, 2021 as chief operating officer and has been leading INDA’s implementation of its new Strategic Plan, as well as updating INDA’s technology platform. This follows decades of leadership experience assisting trade and professional organizations in realizing their organizational and operational potential. A certified public accountant, Fragnito brings strong financial acumen in addition to extensive information technology, human resource and program management accomplishments from organizations representing a variety of professions and industries.

Source: INDA

Mann+Hummel to divest high-performance plastic parts business and focus on filtration

Mann+Hummel Group has signed an agreement to sell its global high-performance plastic parts business to private equity investor Mutares SE & Co KGaA.

The business comprises products other than filtration and separation solutions such as air intake manifolds, high pressure air ducts and fluid reservoirs.

As part of the transaction, Mann+Hummel’s production facilities in Bad Harzburg and Sonneberg, Germany and Laval in France and their 1500 employees will be transferred to Mutares.

“To further strengthen our commitment towards our vision of leadership in filtration and our mission of separating the useful from the harmful, Mann+Hummel has decided to exit the segment,” said Kurk Wilks, president and CEO of the Mann+Hummel Group. “With an absolute focus on filtration and separation solutions in the areas of Transportation and Life Sciences & Environment, we are confident that with this change, we can speed up and further solidify our transformation strategy.”

“We will continue to offer innovative filtration solutions to automotive customers, including International Aftermarket offerings and services,” said Emese Weissenbacher, CFO and executive vice president of the Mann+Hummel Group. “Sharpening our strategic profile allows us to increasingly steer our investments and research in sustainability and alternative drive concepts.”

Mutares focuses on scaling the development potential of medium-sized companies with an established business model and brand.

Source: Mann+Hummel

Norbert Gregor new Group Director at Hengst Filtration

Hengst Filtration announced that Norbert Gregor has joined the Hengst Group, Germany, as Group Director and Managing Director of the business unit Industrial Air Filtration. Gregor assumes his duties in a dual leadership role with Merete Gotfredsen, who heads the Process Air Filtration segment as Managing Director of the business unit. Both report directly to Peter Wink, Group Vice President for Industrial Air Filtration.

The business economist has more than 25 years of management experience – including 16 years in Japan, Mexico, Spain and Italy – and is a specialist in marketing and sales, business development and international corporate management, as well as post-merger integration. He focuses on sustainability and long-term stable value growth and inspires his teams with a motivating leadership style when dealing with international issues.

From 2014, Norbert Gregor was Vice President D-A-CH and Eastern Europe at the Swedish filter specialist Camfil for four years and clearly set the tone for the digitalization of marketing and sales as well as the strategic reorganization towards a strict customer and market orientation.

In 2019, Gregor moved to the Helsa Group as CEO, for which he was the sole managing director and realigned the two business units for molecular filtration (Helsatech) and elastomer technology (Helsacomp), which he sold to Mann+Hummel after a successful reorganization. There, as Global Vice President, he was personally responsible for the post-merger integration of Helsa for two years, thus creating the new molecular filtration segment for the Life Science division for Mann+Hummel.

Source: Hengst Filtration

Nitto acquires Bend Labs, Inc. in the United States

Nitto Denko Corporation in Japan and U.S. company Bend Labs, Inc. have agreed on Nitto’s acquisition of Bend. Bend merges into the Nitto Group on June 1, 2022 and starts its business as Nitto Bend Technologies. Hereafter, they will combine Bend’s sensor device technologies with Nitto’s strengths to develop next-generation technologies and products, and to develop new businesses which utilize sensor-acquired data.

Nitto develops new products and services by strategically devoting resources to Nitto’s three focus domains: Information Interface, Next-generation Mobility, and Human Life. The acquisition of Bend will also accelerate innovation in these domains.

The flexible sensor developed by Bend simultaneously measures “bend”, “stretch” and “force” at high accuracy, in addition to having excellent flexibility and durability. The flexible sensor is expected to meet the evolving technical demands in various fields, including automation in the automotive field and remote monitoring in the digital healthcare field. Through this acquisition, Nitto aims to create new businesses by combining Nitto’s global foundation and core technologies, such as adhesive technology and flexible printed circuit technology, with Bend’s sensor device technology. Besides expected applications in the ever-changing automotive and healthcare fields, Nitto also anticipates these technologies to be utilized in fields such as sports and robotics. Furthermore, Nitto considers building a platform to accumulate sensor-acquired data and deploying services utilizing the acquired data.

Source: Nitto

H&V welcomes seasoned executive James Noonan to the role of CFO at Hollingsworth & Vose

H&V has named longtime finance executive James Noonan to the role of chief financial officer, effective May 23, 2022. A seasoned professional and a fellow member of the Association of Chartered Certified Accountants, Noonan brings more than 20 years of experience in financial management to the CFO role at H&V.

Prior to joining H&V, Noonan served for three and a half years as operations CFO for Suffolk Construction, the largest construction contractor in Massachusetts and one of the 20 largest in the country. From 2016 to 2018, he spent a year each as vice president of finance and CFO for CRH Americas Materials Inc. North Division, a global building materials group that employs more than 85,000 people at 3,600 locations worldwide. Noonan also worked for CRH Americas Materials Inc., CRH Americas Inc. and CRH Plc. from 2007 to 2016 in a range of roles, including group internal auditor, assistant audit manager and corporate controller. Before CRH, he was an accounting manager for tech firm Avaya Inc. and an accountant for Kerry Group Plc., a global food and nutrition company based in Tralee, Ireland.

Born and raised in Ireland, Noonan earned a B.S. in accounting from University College Cork in Cork, Ireland, and an MBA from the Massachusetts Institute of Technology.

Source: Hollingsworth & Vose