In the dynamic and global filtration industry, news and information is breaking on a daily basis. International Filtration News is tracking stories relevant to our industry from air and gas filtration to liquid filtration and the various end-uses for filtration technology. Here we will post news stories relevant to filtration and its downstream applications on an ongoing basis. Please check back for regular updates. If you have news that you feel should be added to this summary report, please email it to Ken Norberg: ken@filtnews.com

Most recent update: December 18, 2025

New Fish-Inspired Filter Removes Over 99% of Microplastics

Researchers at the University of Bonn, Germany have developed a new fish-inspired filter that removes over 99% of microplastics, and this could significantly improve the cleanliness of wastewater.

Water released from washing machines is recognized as a source of microplastics – tiny plastic particles suspected of posing risks to both human and animal health.

The design takes inspiration from the gill arch system found in fish. Early tests show that the patent-pending filter can remove more than 99 percent of plastic fibers from washing machine wastewater. The research findings have been published in the journal npj Emerging Contaminants.

A single washing machine in a household of four can release as much as 500 grams of microplastics each year, most of it generated as fabrics wear down during washing. As a result, washing machines rank among the most significant contributors of these particles. Once released, microplastics pass into the sewage sludge produced at wastewater treatment plants. Because this sludge is often applied as fertilizer, the plastic fibers can eventually spread onto agricultural land. This has prompted researchers and manufacturers to find a more effective way to capture the microplastics before it enters the environment, and lead to the development of the fish-inspired filter.

FLS to Supplier Process Technologies for Gold Project in Ghana

Azumah Resources Gh Limited, has chosen FLS as its strategic technology partner and supplier of all major equipment and main process technologies for its Black Volta gold project development in Ghana, West Africa.

The order for the long-lead equipment and associated technical support services is valued at approximately DKK 235 million and was booked in Q4 2025. The equipment is due to be delivered during 2026, ahead of the mine start-up date in 2027.

As part of the long-lead equipment, FLS will supply the gyratory crushers, a raptor cone crusher, SAG and ball mill, a pre-leach thickener, screens, apron feeders and KREBS cyclones and pumps. The order also includes equipment for absorption, desorption and refining and detoxification.

FLS will also provide technical support to the EPC contractor during the detailed engineering phase and site support for erection and installation, start-up, commissioning and site training. In addition, the order includes spare parts as well as a performance guarantee for the process equipment.

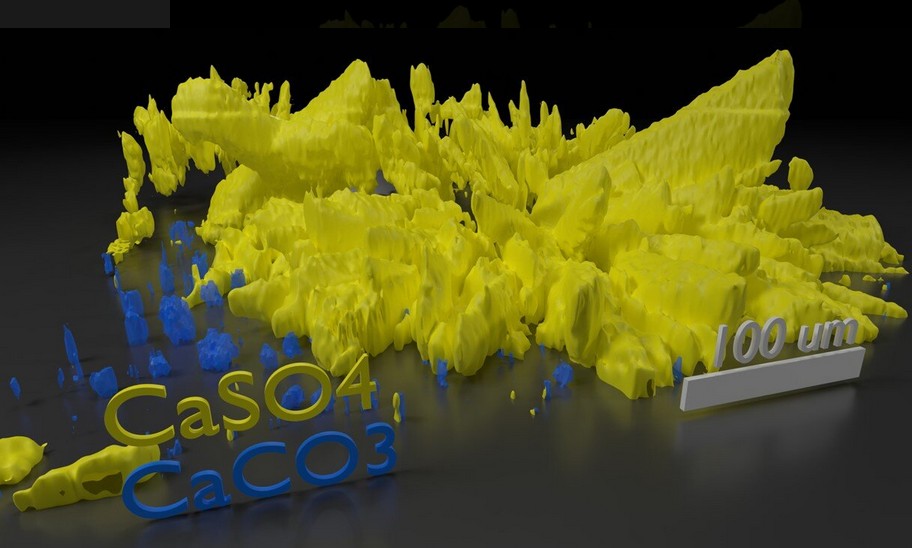

Real-Time Membrane Imaging for Sustainable Water Filtration

CU Boulder researchers have introduced a solution to improving the performance of large-scale desalination plants: stimulated Raman scattering (SRS).

Published in the journal Environmental Science & Technology, the laser-based imaging method allows researchers to observe in real-time membrane fouling, a process where unwanted materials such as salts, minerals and microorganisms accumulate on filtration membranes.

Worldwide, 55% of people experience water scarcity at least one month a year, and that number is expected to climb to 66% by the end of the century.

Desalination—turning saltwater into fresh water—is critical for communities globally as demand increases.

Modern reverse osmosis (RO) plants make up about 80% of the world’s desalination facilities, placing greater importance on having them run efficiently.

FTC Sues to Stop Loctite, Liquid Nails Construction Adhesive Merger

The Federal Trade Commission in the USA has sued to block Henkel AG & Co. KGaA (Henkel), the manufacturer of the industry-leading Loctite brand construction adhesives, from acquiring Loctite’s main competitor, Liquid Nails. The FTC’s enforcement action seeks to lower the cost of housing for Americans by protecting U.S. consumers from paying higher prices for the materials they use to build and maintain their homes.

Under the terms of the proposed deal, Henkel and its U.S. subsidiaries seek to acquire Liquid Nails for $725 million from private equity firm American Industrial Partners. The deal would combine the two biggest brands—by far—of construction adhesives sold at retailers like The Home Depot, Lowe’s, and Ace Hardware, according to the FTC’s complaint.

The FTC alleges that the merger would eliminate fierce competition between Loctite and Liquid Nails, leading to higher prices, lower quality, and reduced innovation, all of which would be detrimental to American consumers.

Ahlstrom Launches Flow2Save™ Filtration Media

Ahlstrom, a global leader in sustainable fiber-based materials, has introduced an enhanced version of Flow2Save™ filtration media. The advanced solution is specifically designed to improve indoor air quality while significantly reducing energy consumption.

Flow2Save™ offers a compelling value proposition built on Ahlstrom’s deep expertise and commitment to sustainable innovation. The nanofiber-enhanced gradient structure extends filter life and reaches the highest energy efficiency while meeting ISO 16890 standards from ePM1 60% to ePM1 80%.

With advanced media engineering, Flow2Save™ delivers up to 50% higher dust-holding capacity and reduces initial pressure drop by an average of 30% compared to conventional filter media. In filter element evaluations, Flow2Save™ has demonstrated the potential to achieve up to 50% energy savings, supporting more sustainable building operations.

Efficient filtration is essential for protecting both human health and industrial processes. Flow2Save™, produced in Tampere, Finland, lowers energy use and operational costs while setting a new benchmark in HVAC and Air Intake performance.

Camfil Acquires F.C.R. in Italy

Camfil has acquired F.C.R., a respected Italian company specializing in air filtration solutions. The acquisition will take effect on January 1, 2026.

The acquisition expands Camfil’s presence in Italy and strengthens its ability to serve customers with reliable, energy‑efficient solutions for cleaner air. By combining Camfil’s global reach with F.C.R.’s local expertise, Camfil will offer a broader range of products and services designed to improve indoor air quality and environmental performance.

F.C.R. has built a strong reputation over decades for technical know‑how, product innovation, and responsive customer service. The company is known for its deep expertise in filtration design and manufacturing, delivering solutions that meet strict performance standards. Its experience makes F.C.R. a trusted partner for customers in sectors where air quality is critical and reliability is non‑negotiable.

Nanostone Launches PFAS-Free CUF|Flow™ Ceramic UF Module

Acuriant Technologies Inc., the company behind the Nanostone ceramic ultrafiltration (UF) brand, recently introduced CUF|Flow™, a new high-capacity PFAS-free UF module designed for municipal and industrial applications. The launch expands the company’s ceramic UF portfolio to three modules, each developed for different water qualities and space constraints.

The new CUF|Flow™ was introduced at the Innovation Driven Water Sustainability Conference (IDWS 2025) in Jeddah, Saudi Arabia. The debut is Nanostone’s third new product in a year, building on the CUF|Shield module released earlier in 2025. The company said the broader portfolio is intended to help utilities cope with increasingly variable raw water quality, tightening regulatory expectations, and space constraints.

CUF|Flow is a capacity-enhancing module with 40% more active membrane surface area within the same housing dimensions as CUF|Shield. This supports two deployment strategies: boosting water output by up to 40% from an existing rack or reducing module count by nearly 29% for the same production rate.

Covestro and Allmed Join Forces to Recycle Kidney Filters

Covestro and Allmed announced a groundbreaking partnership to explore the recycling of used artificial kidney filters. This collaboration aims to recover polycarbonate from medical devices, paving the way for new materials with recycled content and advancing sustainability in healthcare.

The initiative seeks to establish a circular economy model for medical devices by demonstrating both technical feasibility and economic viability. Additionally, the study will address the complex regulatory landscape surrounding medical waste management.

“The circular economy in healthcare is still emerging – but it holds tremendous potential. With this feasibility study, we want to demonstrate that even complex applications like artificial kidney filters can be circular and become a valuable source of high-quality polycarbonate recyclate instead of being incinerated or sent to landfill,” says Lily Wang, Global Head of Engineering Plastics at Covestro.

Ahlstrom Invests in North American Filtration

Ahlstrom, a global leader in fiber-based specialty materials, announced a strategic investment to upgrade the existing Taylorville, IL (USA) line to enhance its capability to produce advanced synthetic filter materials.

The upgraded line is expected to begin operations in the final quarter of 2026, enabling customers to meet rising demand for sustainable and efficient filtration solutions.

Synthetic filtration materials are essential for high-performance applications across demanding industrial environments and transportation applications. Materials deliver superior filtration through higher efficiency, greater dust-holding capacity, and exceptional durability—even under the most demanding operating conditions.

The line will produce materials with up to 100% synthetic fiber composition, including optional fiber blends of glass and/or cellulose. It supports both, single and dual-layer filter material designs and includes saturation and corrugation capability, ensuring flexibility and consistent performance across a broad range of filtration applications.

WaterSurplus Announces Certification for NanoStack™ Membrane Coating

WaterSurplus, a leader in sustainable water treatment, announced that its NanoStack™ Coating for RO membranes is now NSF/ANSI/CAN 61 certified. This prestigious designation indicates that this membrane coating has been independently tested and verified by IAPMO R&T, North America’s premier plumbing and mechanical product certification agency.

This is an important development for WaterSurplus, as its NanoStack technology is a core component of the company’s ImpactRO™, a breakthrough brackish water reverse osmosis (BWRO) system that integrates multiple technological advancements into a single transformative platform.

Equipped with NanoStack coated membranes, ImpactRO can achieve up to 96% product recovery, along with up to a 4× reduction in membrane fouling, up to a 4× reduction in system downtime, and as much as double the membrane life compared to conventional multi-stage BWRO systems. It is exceptionally well-suited for rapidly fouling environments, high-recovery and high-efficiency applications, and water reuse or reclamation systems.

The NSF/ANSI/CAN 61 certification represents the internationally recognized benchmark for drinking water product safety and quality. IAPMO R&T’s certification program entails a comprehensive evaluation of materials, manufacturing practices, and product performance, supported by ongoing audits and periodic retesting to verify sustained compliance.