Cerahelix’s NanoHelix and PicoHelix membrane filters build upon the inherently robust and durable nature that makes ceramics a good fit for harsh operating environments. The ability of these membranes to achieve nanofiltration opens the door to a myriad of applications for which traditional ceramic membrane technology has not been well suited.

Ideal for use in challenging chemical and thermal conditions, Cerahelix’s robust membranes provide longer life and higher efficiency. The smooth hydrophilic membranes have a glass-like surface that can be cleaned quickly, easily and efficiently with forward flush.

Cerahelix’s ceramic nanofiltration membranes also simplify traditional multi-stage treatment processes typically used for industrial wastewater treatment. They do not require pre-treatment, thus simplifying system design and reducing the footprint for lower capital and operational costs.

Technology overview

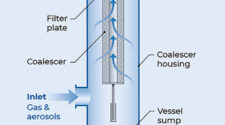

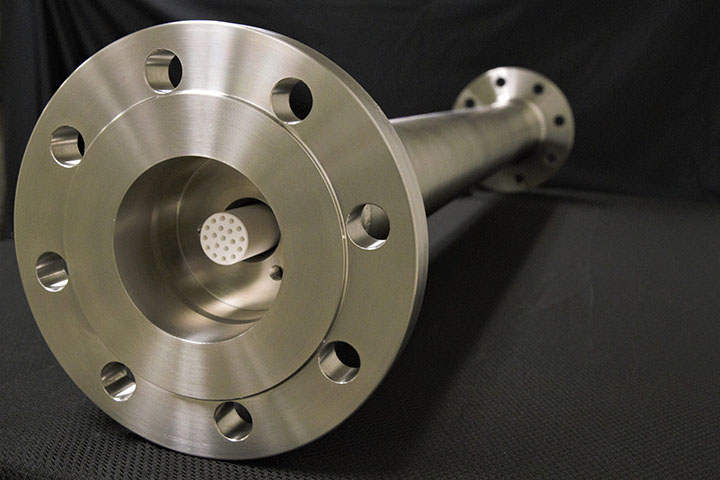

Cerahelix manufactures its pressure-driven tubular ceramic nanofiltration membranes for use across various market sectors and applications – from industrial wastewater reuse to food & beverage to biopharmaceuticals to nutraceuticals. The nanofiltration membranes are manufactured using the company’s patented thin-film and DNA templating technology to approach Reverse Osmosis (RO)-level purity, while offering the robustness of ceramic membranes with lower operating costs. The membranes provide high removal of Chemical Oxygen Demand (COD), divalent salts and sugars, while operating at recoveries of over 90%.

Cerahelix employs thin-film technology designed to create a colloidal sol-gel membrane with a proprietary templating process to manipulate strands of DNA within the ceramic substrate. This allows individual strands of DNA to be arranged precisely within a sol-gel substrate. This allows Cerahelix to create sub-nanometer pores within the ceramic membrane that are extremely uniform in size, shape and smoothness.

These features combine to make a membrane that filters at high flux with a narrow pore size distribution. The resulting membrane has sub-nanometer diameter pores capable of rejecting molecules down to 400 Da in size, extending the size cutoff range beyond what is currently achievable by traditional ceramic membranes. Specifically, the NanoHelix filters retain solutes down to a molecular weight cutoff (MWCO) of 700 Da, while the PicoHelix uses the power of biochemistry to create a DNA-templated ceramic membrane that retains solutes down to a MWCO of 400 Da. Both products are available in 19- and 85-channel configurations.

Three key features

- Simple treatment process: Cerahelix’s single-stage treatment yields both Capex and Opex savings while also occupying a 50% smaller footprint. Despite their ability to simplify the treatment process, Cerahelix ceramic nanofilters can concentrate up to 25% solids and accommodate a feed water with TDS up to 50,000 ppm.

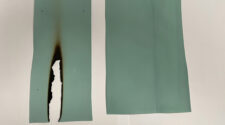

- Robust and easy to clean ceramic: These ceramic filters tolerate high temperatures and chlorine, and are resistant to solvents. They are shown to have up to 5x longer life when compared to polymeric membranes. In addition, these smooth hydrophilic membranes are easy to clean with forward flush – no backwash is required – and their hydrophilic separation surface makes them resistant to fouling.

- Low MWCO: With their low molecular weight cutoff as low as 400 Da, these membranes provide 100% TSS removal and well as high removal of COD, divalent salts and sugars without using RO.