Industry-Standard Filtration Tests Aren’t Telling the Whole Story

Are industry standard tests keeping pace with evolving customer needs? Standards play critical roles in keeping diesel equipment running, and they are needed. But when it comes to diesel fuel filtration, customer needs are evolving faster than standards can address.

Although standardized tests can provide insight into filter life and efficiency, they don’t always tell the whole story. Customers care about real-world performance and the bottom line. How well will their equipment be protected? How often will they need to service the filter? How will their filtration needs impact their total operating costs?

To enable our customers’ success, we must also go beyond industry testing to provide filtration solutions that more closely simulate the dynamic and real-world conditions our customers experience.

Old Standards Aren’t Keeping Pace With New Challenges

Technological developments and changing market needs are creating challenges that current standardized test methods aren’t equipped to handle.

For example, a trucking fleet in Brazil recently experienced widespread short service life or cycle issues. Everything from macroeconomic shifts in the biodiesel supply base to advances in fuel systems – two factors not easily identified through standardized testing – caused their filters to fill up with contaminants twice as fast, resulting in short service life while causing unplanned and unwanted maintenance.

Standardized methods run capacity tests with hard dust particles of a certain size for a set period. But this isn’t always representative of what plugs a filter in today’s operating conditions. Today, filters are more likely to be plugged with soft, sticky organic material with smaller particles, especially if biofuels are blended in.

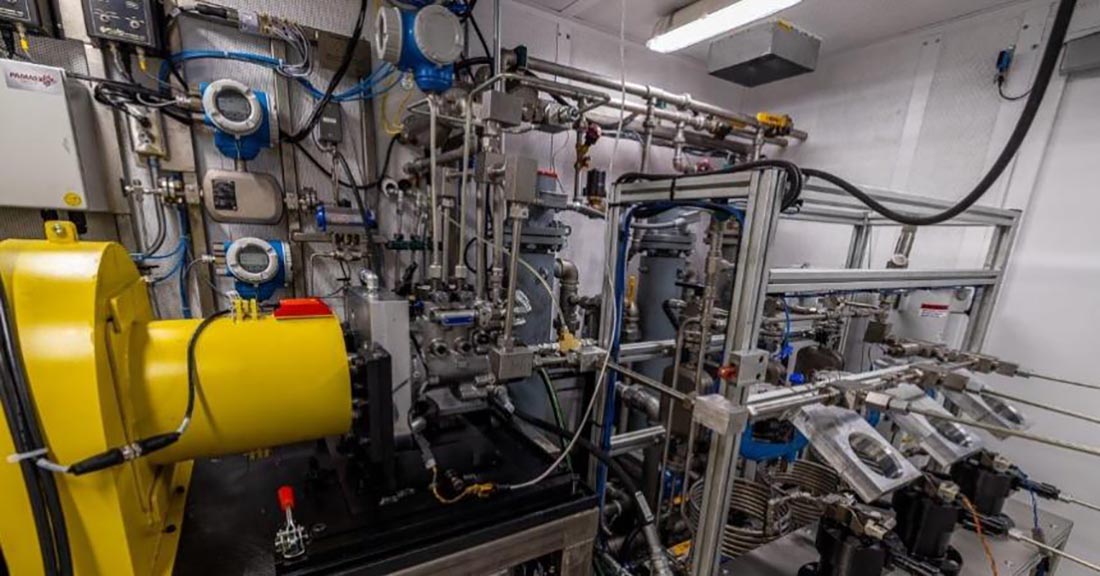

In Brazil, the customer needed to get to the root of the problem right away but knew it required more than standardized data. They turned to Atmus Filtration Technologies

for help.

Atmus was able to deploy on-site fuel testing to analyze and understand the real-world fuel contamination. Then, recreating these conditions in the lab resulted in a more effective solution that captured smaller particles – protecting the engine, extending service life and delivering the expected service intervals.

Greater Fuel Variation Is the New Normal

A decade or two ago, it was possible to take a “one-size-fits-all” approach to filtration technology, in part because engine and fuel system designs provided more clearance. The same systems would deliver comparable performance, whether they were used in North America, South America, Europe or anywhere else.

This approach doesn’t work anymore. The biggest factors our customers face include:

- Changes in diesel fuel-injection equipment – Most modern diesel engines use a high-pressure common rail (HPCR) fuel system or similar technology to meet stricter emissions standards. This type of equipment is extremely sensitive to small particles; it’s now necessary to protect the system from smaller particles than in the past (typically four microns, or smaller than a red blood cell). Filters today must capture more material, meaning they are at risk of plugging faster. Innovation is therefore necessary to extend service intervals.

- Modern pressurized fuel systems – Pressurizing fuel raises its temperature, creating more contamination as it moves through the system. As a result, filters are up against additional contaminants that weren’t generated by the mechanical or electrical fuel systems of the past.

- Aging infrastructure – Many of the world’s fuel pipelines are aging. Fuel delivered through aging pipes dislodges rust and other contaminants that have built up over time, carrying them into the distribution system. Each fill-up delivers fuel pumped through different pipelines, giving customers less control over what their systems are exposed to. Filters need to be ready for anything.

- Biofuel content – There’s significant variability in global biofuels, even in the U.S., where biodiesel blends up to B5 don’t have to be labeled. Although these fuels can often be used as drop-in replacements for ultra-low sulfur diesel, their chemistry can present different challenges to filter life and performance.

All these factors are driving the need for greater innovation to create more capacity in filters so that customers don’t have to settle for shorter service intervals. Going beyond industry standard testing can help us get there.

Protecting Your Equipment

Next time you are evaluating a filtration solution, ask yourself how it will perform for your application. Look for a provider who can demonstrate that they’ve gone beyond industry standard tests to test for real-world performance.