In the dynamic and global filtration industry, news and information is breaking on a daily basis. International Filtration News is tracking stories relevant to our industry from air and gas filtration to liquid filtration and the various end-uses for filtration technology. Here we will post news stories relevant to filtration and its downstream applications on an ongoing basis. Please check back for regular updates. If you have news that you feel should be added to this summary report, please email it to Ken Norberg: ken@filtnews.com

Most recent update: November 21, 2025

EQT Future to Acquire a Majority Stake in DESOTEC

EQT announced that the EQT Future fund has agreed to acquire a majority stake in DESOTEC, a leader in circular mobile filtration solutions, from private equity funds managed by Blackstone, which will remain a minority investor.

As part of the transaction, EQT is partnering with two renowned German family offices, Athos and Merckle, who will co-invest alongside EQT Future.

Founded in 1990 and headquartered in Roeselare, Belgium, DESOTEC helps customers remove pollutants such as VOCs, PFAS, and hydrogen sulfide from air, water, and soil. The Company’s circular “Filtration-as-a-Service” model integrates mobile filter rental, logistics, and in-house carbon reactivation, providing customers with a cost-efficient way to meet increasingly stringent environmental standards BY minimizing emissions and waste.

DESOTEC operates the world’s largest fleet of mobile (re)-activated carbon filters, combining innovative technical solutions to more than 2,000 customers across Europe and North America. The Company’s business model generates strong recurring revenues and customer retention, underscoring the mission-critical nature of its service and DESOTEC’s compelling value proposition for customers.

EQT and Blackstone plan to support DESOTEC’s continued growth across Europe, where significant growth opportunities remain in less penetrated markets, and to accelerate its expansion in North America, where the Company established operations in 2023. The North American market for mobile filtration is still in its early stages but is underpinned by a growing focus on air and water quality, as well as rising demand for circular, compliance-driven solutions.

Toray Integrate Reverse Osmosis Membrane Fabrication in Saudi Arabia

Toray Industries, Inc., announced that Toray Membrane Middle East LLC (TMME) has expanded capacity for desalination reverse osmosis (RO) membranes by initiating operations at a new facility in Dammam, Saudi Arabia. That upgrade made the company the first in the nation to integrate everything from membrane manufacturing through assembly. Toray will continue to support water infrastructure in the rapidly industrializing Middle East and North Africa region.

On November 12, 2025, TMME held a ceremony to commemorate that launch and the opening of the Middle East Water Treatment Engineering Center (MEWTEC), which became operational in April 2025. The numerous distinguished guests included His Royal Highness Prince Saud bin Nayef bin Abdulaziz, Governor of the Eastern Province, representatives of various ministries and agencies, Japan’s Ambassador to Saudi Arabia, and local business leaders. This ceremony celebrated these milestones, which reflected the achievements and trust that Toray has built over more than a decade of joint ventures with Saudi entities and signaled expectations for further development.

Recent years have witnessed a transition from conventional evaporation techniques to membrane water treatment at desalination plants, significantly reducing energy consumption. With population growth and industrial development making water shortages more severe, membrane-based desalination technology is becoming essential for securing sustainable water resources. Expectations are also rising for energy-saving, high-performance membrane technology.

The new facility and MEWTEC will strengthen Toray’s capacity to deliver timely, energy-efficient membrane technology and help address regional water challenges.

AqueoUS Vets Appoints Harland Pond as VP of Sales

AqueoUS Vets (AV) has appointed Harland Pond as vice president of sales, strengthening its senior leadership team as the company expands its work in PFAS and emerging contaminant treatment across the United States.

AV is a vertically integrated manufacturer of treatment systems designed to remove PFAS and other contaminants of emerging concern from groundwater and drinking water supplies. The company operates manufacturing facilities in California and Florida, providing turnkey solutions from design and fabrication to installation, commissioning and long-term service support.

In his new role, Pond will guide AV’s overall sales strategy, leading both internal teams and the company’s national network of channel partners. His remit includes developing strategic key account programs, supporting sales team performance and building partnerships with engineering and consulting firms across the water sector.

Parker Hannifin to Acquire Filtration Group Corporation

Parker Hannifin Corporation, a global leader in motion and control technologies, announced that it has entered into a definitive agreement to acquire Filtration Group Corporation on a cash-free, debt-free basis for a cash purchase price of $9.25 billion, which represents 19.6x Filtration Group’s calendar year 2025 estimated adjusted EBITDA, or 13.4x including expected cost synergies. The purchase price is expected to be financed with new debt and cash on hand. The transaction is subject to customary closing conditions, including receipt of applicable regulatory approvals, and is expected to close within six to twelve months.

Filtration Group, a U.S. based private company and affiliate of Madison Industries, adds complementary filtration technologies serving key growth markets with strong product brands that are often validated and specified. The company’s highly engineered products use proprietary media and leverage strong technical and application knowledge and processes. Approximately 85% of sales are generated in the aftermarket, creating strong recurring revenue streams across multiple product platforms. Filtration Group has a strong organic growth profile and serves high value, performance-critical applications. Filtration Group expects calendar year 2025 sales of $2 billion with adjusted EBITDA margin of 23.5% and employs approximately 7,500 team members serving customers around the world.

“This strategic transaction continues our investment in high quality businesses that continue to transform our portfolio, accelerate sales growth and improve profitability,” said Jenny Parmentier, Parker’s Chairman of the Board and Chief Executive Officer.

“Filtration Group is excited to become part of Parker,” said Jon Pratt, President and Chief Executive Officer of Filtration Group. “Together, our mission-critical offering of advanced filtration technologies will create a broader portfolio of solutions for customers in key growth markets around the world. Parker is an exceptional company, and we are confident Filtration Group will benefit from Parker’s increased scale, technical knowledge and disciplined approach to driving growth and operational excellence.”

Amazon Filters Expands European Presence with New Warsaw Production Facility

Amazon Filters, a leading UK-based manufacturer of process filtration systems for the water treatment and industrial sectors, has opened a new 2,800 m² production, warehouse and office facility near Warsaw, Poland. The expansion marks a significant milestone in the company’s European growth strategy and pushes total investment across the region beyond £1 million.

The new site, located at CTPark Nowy Konik, positions Amazon Filters’ Polish subsidiary as the park’s first tenant. The facility will significantly boost production capacity and improve logistics links across Europe, serving sectors including municipal water, food and beverage, pharmaceuticals, and energy.

Atlas Copco Expands in Brazil

MKG Equipamentos Ltda., a Brazilian process filtration solutions company, has become part of Atlas Copco Group.

MKG, established in 2002, designs, manufactures and distributes industrial process filtration solutions such as strainers, cartridges, housings, self-cleaning filters and mixers. The company is located in São Paulo, Brazil and has 30 employees who will join Atlas Copco Group as part of the acquisition.

The company’s main customers can be found within the pharmaceutical, food & beverage and energy industries, as well as in general industry.

“We are very pleased to welcome MKG to the Group”, said Philippe Ernens, Business Area President Compressor Technique. ”With this acquisition we are adding advanced filtration technologies to our portfolio and increasing our presence in the region.”

The purchase price is not disclosed. During 2024 MKG had revenues of approximately 47 MBRL (90 MSEK*).

The business has become part of Medical Gas Solutions division within the Compressor Technique Business Area.

Electrolux Professional Group Partners with Mimbly – a Cleantech Company

Electrolux Professional has partnered with Mimbly, a Swedish startup cleantech company focused on water saving and microplastic filtration technology.

“By partnering with Mimbly, we will strengthen our commitment to sustainable innovation by supporting the development of microplastics filtration and water saving technology. This will further strengthen our position as the sustainability leader in our industry“ said Paolo Schira, President Business Area Laundry, Electrolux Professional.

Mimbly has developed a technical plug-in solution called Mimbox that lowers water consumption, filters microplastic down to around 50 micron, and saves energy from retaining the water. Electrolux Professional and Mimbly will co-develop new solutions within the field of microplastic filtration.

The continued need to be more efficient in water and energy usage, in combination with the preparation for any future regulatory requirements are key drivers for partnering with Mimbly.

Electrolux Professional will also take a minority stake in Mimbly.

Ahlstrom Launches Flame-Retardant Paper

Ahlstrom, a global leader in fiber-based specialty materials, has introduced a new flame-retardant paper enhanced with Flame-Gard™ technology —engineered to meet the demanding fire safety and durability needs of spray-painting booths and industrial workshops.

Certain versions of this specialty paper can serve as protective coverings for walls, ceilings, and floors in workshop environments while others can be converted into filter components for spray painting booths—each tailored to meet the specific demands of their application. When exposed to fire, the paper chars without combusting and self-extinguishes once the flame source is removed, offering a critical layer of safety in high-risk areas.

Beyond its flame-retardant properties, the paper delivers excellent mechanical strength and dimensional stability, helping maintain surface integrity during installation and use. It also achieves a rare balance between high flame resistance and low water absorption—making it ideal for environments where moisture and overspray are common.

PPG Introduces Ultrafiltration Antifouling Membrane

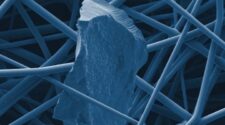

PPG announced the introduction of an ultrafiltration (UF) antifouling membrane for industrial water purification and treatment to its portfolio of spiral-wound filter elements. Developed to meet growing demand for sustainable UF filtration solutions, the new membrane is engineered to handle extremely hard-to-treat water containing a wide range1 of oily waste and other contaminants, enabling safe and economical disposal or reuse.

The new UF membrane features a super-hydrophobic (water-repelling) surface that resists fouling from trace amounts of oil, grease and other tough-to-remove contaminants. By reducing fouling, the technology can extend membrane service life, lower maintenance costs and minimize downtime for some of the most challenging industries. Unlike other UF and microfiltration (MF) membranes currently on the market, PPG’s entire portfolio is produced using a proprietary composite material that does not contain intentionally-added polyfluoroalkyl substances (PFAS).

Applications for the UF membrane include offshore and onshore oil-water separation, dry dock and in-water marine ship treatment, industrial process water and wastewater, automotive and industrial paint lines, and graywater treatment. PPG has invested in equipment and technology to produce the membrane at its Barberton, Ohio, facility to meet growing market demand.

PPG’s high-performance microfiltration (MF) and UF membranes separate oil, grease and emulsified contaminants from industrial process water at higher throughputs than conventional membranes. This reduces the number of filters and the amount of floor space needed to recover the water for reuse while improving cleanability and ensuring long-term durability.