5K Fibres, located in Neenah, WI, has developed a proprietary process for producing polyvinyl alcohol (PVOH) as a nonwoven fabric, unlocking new possibilities for sustainable materials. By combining unique processing capabilities with thermoplastic PVOH’s unique chemistry, this innovation enhances application potential and productivity—without compromising functionality or end-of-life credentials.

Polyvinyl alcohol (PVOH) is a versatile, water-soluble polymer recognized for its biodegradability, film-forming ability, and superior barrier properties. Traditionally used in film applications for its resistance to oils, greases, and many organic solvents, PVOH also offers excellent gas and aroma barrier performance. Now, 5K Fibres is extending these benefits to nonwoven formats.

Potential applications include:

- Temporary protective covers

- Sanitary products and other single-use disposables

- Filtration media

- Anti-static packaging for electronics

- Unit dosing for chemicals

- Carriers for waterless cosmetics or detergents

- Embroidery backing

This advancement positions PVOH nonwovens as a game-changer for industries seeking sustainable, high-performance solutions.

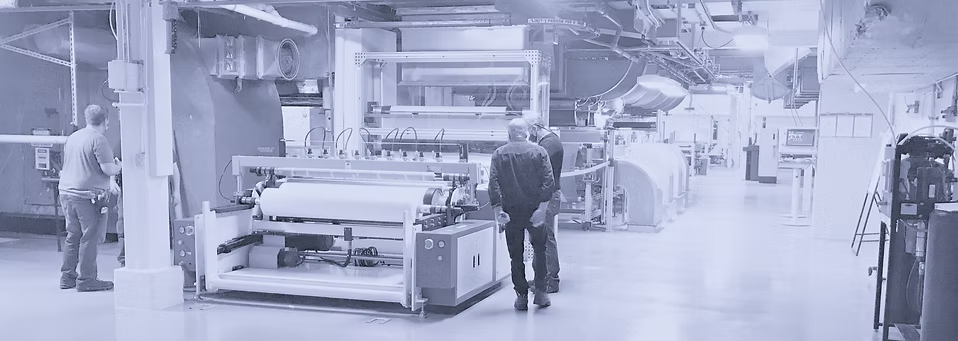

5K Fibres is a wholly owned subsidiary of Biax-Fiberfilm, founded in 1975, which has engineered and manufactured nonwoven production systems for customers worldwide.