What Every Plant Operator Should Know

Choosing the right cartridge filter can reduce cleaning cycles, cut utility costs, and improve dust collection performance—all while keeping emissions low.

Dust collection systems are a critical part of industrial plant operations — but one component is often underestimated in its impact: the filter media. Whether you’re overseeing maintenance, purchasing consumables, or working to reduce operating costs, understanding how different filter media perform can make a measurable difference in your bottom line.

Today’s most common cartridge filters rely on one of three media types:

- Pure cellulose

- An 80/20 blend of cellulose and synthetic fiber

- Cellulose topped with a nanofiber layer

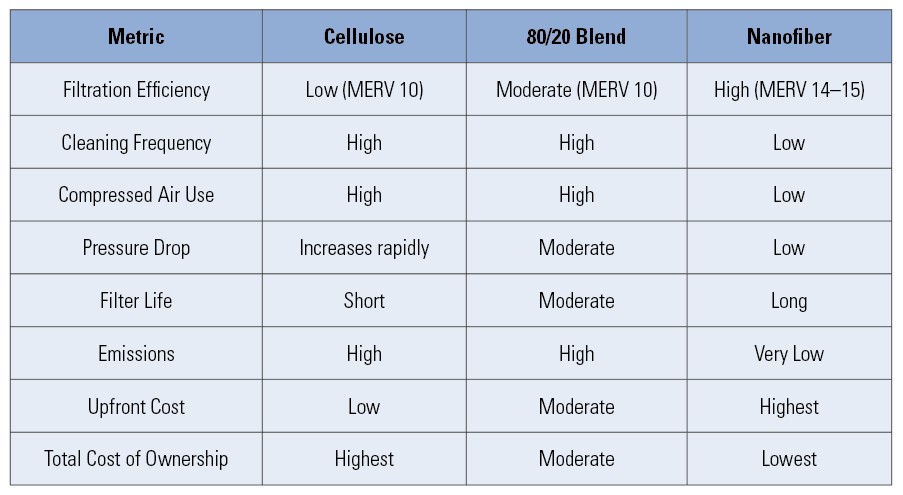

All are widely available and relatively affordable—but they don’t perform equally. And for plant operators seeking better reliability and lower lifecycle costs, nanofiber media stands out.

Surface Loading vs. Depth Loading

Cartridge filters operate on two basic principles: depth-loading and surface-loading.

Cellulose and 80/20 filters are depth-loading, which means they trap dust throughout the full thickness of the media. Dust builds within the fibers, forming a dense cake that improves particle capture but also increases resistance to airflow. Over time, this rising pressure drop requires frequent cleaning with compressed air. Eventually, embedded dust can’t be removed, and the filter must be replaced.

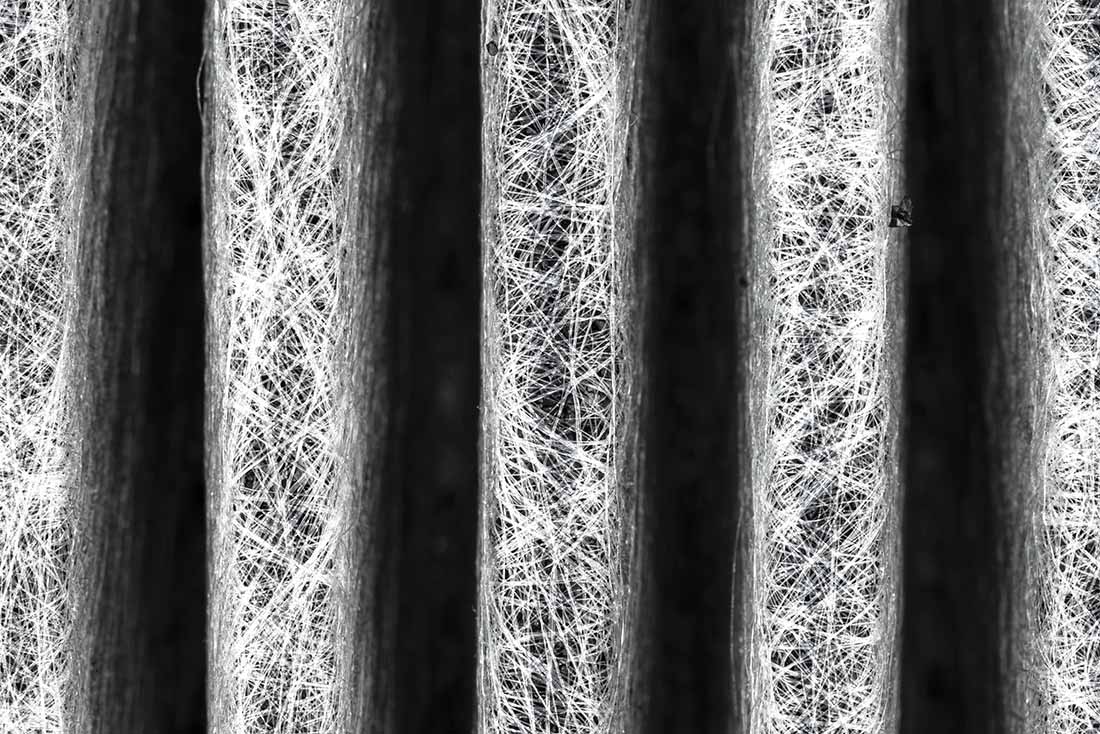

By contrast, nanofiber filters are surface-loading. An ultrathin nanofiber layer—laid over a cellulose substrate—captures most particles on its outer face. The underlying layer remains largely free of contamination. This structure reduces cleaning demands and maintains lower pressure drop for longer.

The True Cost of Cleaning

Pulse-jet cleaning may restore filter performance temporarily, but it comes at a cost.

Compressed air is one of the most expensive utilities in a dust collection system.

Depth-loading filters typically require more frequent pulsing—as often as 17 times per cleaning cycle—to restore airflow. In contrast, nanofiber filters may only need one or two pulses. The result: less wear and tear, lower utility costs, and a longer filter lifespan.

Additionally, dust released during cleaning doesn’t all go into the hopper. A portion escapes into the atmosphere—known as fugitive emissions. Standard cellulose filters can emit 35 times more dust than nanofiber cartridges, which not only require fewer cleanings but also trap finer particles.

Nanofiber filters require fewer cleaning pulses, reducing compressed-air use and emissions—two of the most costly aspects of dust collection.

Efficiency That Doesn’t Compromise Airflow

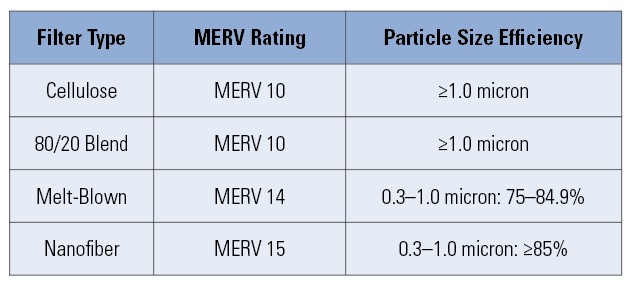

Filter efficiency is commonly rated using MERV (Minimum Efficiency Reporting Value), a scale developed by ASHRAE. It measures how well a clean filter captures particles of various sizes.

But MERV isn’t everything. Some filters achieve high MERV ratings by adding a melt-blown layer, but this increases media depth and pressure drop. Nanofiber filters strike a better balance: their thin outer layer does nearly all the filtration work, while the porous substrate underneath allows air to flow with less resistance.

Lower pressure drop means less fan horsepower is needed, reducing energy consumption. Over time, this can translate into meaningful cost savings.

Total Cost of Ownership: A Winner

When evaluating filters, don’t stop at the price tag. Look at performance over time, including:

- Number of cleaning cycles

- Compressed-air usage

- Power consumption

- Filter replacement intervals

- Emissions

Bottom line: Nanofiber filters may cost more upfront, but they last longer, use fewer resources, and emit less dust—a win-win for both performance and compliance.

Selection Tips for Plant Operators

Although nanofiber filters offer numerous advantages, no single solution fits every application. When selecting a filter:

- Don’t rely solely on MERV ratings.

- Test filters in your actual equipment under real dust loading conditions.

- Consult with filtration experts who understand your process.

- Seek feedback from peers in similar industrial settings.

Because no industry-wide metric combines all relevant performance factors—cleanability, emissions, pressure drop, and filter life—hands-on evaluation remains essential.

The next time you’re replacing dust collector filters, consider the bigger picture. Nanofiber filters offer high efficiency, longer service life, and significant operational savings—benefits that go far beyond their purchase price.

As plants face increasing pressure to reduce emissions and energy use, upgrading your filter media could be one of the easiest wins on the table.