In the dynamic and global filtration industry, news and information is breaking on a daily basis. International Filtration News is tracking stories relevant to our industry from air and gas filtration to liquid filtration and the various end-uses for filtration technology. Here we will post news stories relevant to filtration and its downstream applications on an ongoing basis. Please check back for regular updates. If you have news that you feel should be added to this summary report, please email it to Ken Norberg: ken@filtnews.com

Most recent update: September 19, 2025

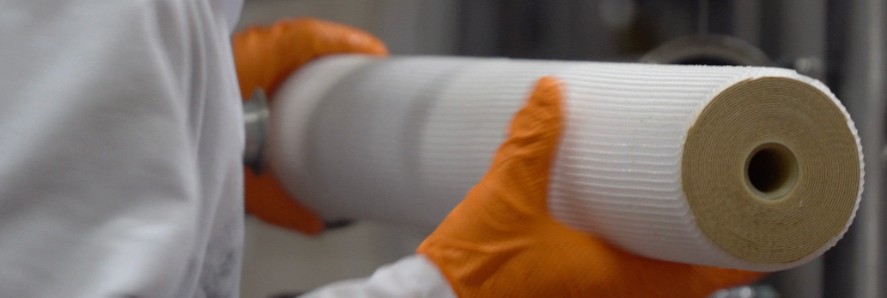

Pall Enables Sustainable Food Production at a Lower Cost with Membralox®

Pall Corporation, a leading provider of filtration, separation and purification solutions launched Membralox® GP-IC ceramic membrane systems, a revolutionary ceramic membrane with graduated permeability along the length of the filter. This unique design increases processing efficiency, lowers capital and operating costs and has the potential to yield up to 95% recovered value-add products enhancing overall filtration performance.

With a high surface area and multi-channel geometry, the Membralox GP-IC membranes offer up to 45% more filtration capacity compared to conventional ceramic filters of similar size. This enables optimized system loop design with more compact filter modules, reducing capital and operational expense.

“The unique design of Membralox GP-IC pushes the boundaries of what’s possible for ceramic membrane solutions in order to meet the demands of food processors globally,” said Ankush Soni, Vice President & General Manager of the Food and Beverage business unit of Pall Corporation. “We are excited to launch this breakthrough solution and support our customers with a smarter, more efficient and sustainable solution.”

Pall has a long history of expertise and innovation in the ceramic membrane industry, which is poised for exponential growth ($21 billion by 20301). Through filtration expertise as well as a deep understanding of the unique challenges of global food industry, Pall was able to design a solution enables customers to be at the forefront of sustainable and efficient food production.

Rensa Filtration acquires Irema-Filter of Germany

Rensa Filtration, an Audax Private Equity portfolio company and manufacturer and distributor of consumable, mission-critical air filtration solutions, announced that it recently acquired IREMA-Filter GmbH and its U.S. subsidiary Aeolus Filter Corporation from PINOVA Capital.

IREMA was founded 50 years ago near Postbauer-Heng, Germany and is an innovator in filtration media and filter media pleating technologies. Based in Archdale, NC, Aeolus Filter provides filters using IREMA’s media and pleating technologies and has a strong market presence in critical data center and healthcare air filtration applications.

Brandon Ost, CEO and Founder of Rensa Filtration, noted, “We’re excited to partner with the IREMA and Aeolus management team, employees and their customers. The filtration market has long held the IREMA/Aeolus business and filter technology in high regard, and we look forward to supporting their continued technology development, increased manufacturing capacity and commercial growth. This investment in IREMA underscores Rensa’s commitment to quality and innovation.”

IREMA’s filter media process technology is a flexible platform capable of making both polymeric microfibers and nanofibers and combining them to make innovative filter media structures with multiple layers, gradient structures, and mixed micro and nanofiber structures. For end users, these technologies enhance both the dust-holding capacity and service life. The media can be electrostatically charged or fully mechanical in nature. Because it is completely polymeric, the media has high moisture resistance and mechanical durability and does not support microbial growth. Finished filters can be recycled or sent to waste-to-energy facilities.

FLS to Deliver the World’s Largest Filtered Tailings System

Following a long-standing partnership, a progressive Indian miner and steelmaker has selected FLS to deliver core mining technologies to what is set to become one of the world’s largest, most efficient and sustainable iron ore beneficiation plants globally. This is the fourth consecutive order that FLS has received from the customer within the past nine months.

The order includes the delivery of the world’s largest filtered tailings (“dry tailings”) system comprising of twenty-two 4.2-meter x 162-sq. meter Horizontal Belt Filters (HFB), which also will be the largest of their kind in the world, as well as twelve 12 x 55-meter diameter high-rate thickeners (HRT). The technologies are expected to be delivered to the customer in 2026.

The addition of these technologies to the flowsheet and their crucial placement throughout the overall process flow demonstrates FLS’s commitment to sustainability, in this case, particularly water recovery. Furthermore, this order confirms FLS’s technology as the preferred solution for resource conservation and operational efficiency.

The value of the order has not been disclosed.

Purgo Holdings, LLC Announces the Acquisition of Puroflux Corporation

PURGO Holdings, LLC announced the acquisition of Puroflux Corporation from Montage Partners. Puroflux is a Simi Valley, CA based manufacturer of filtration and controls products serving the HVAC, commercial and process cooling industries.

This acquisition is PURGO’S sixth since its formation, and expands the company’s product offerings to include controls, pump packages and a broad range of sand filtration products. “We are excited to welcome Puroflux to PURGO,” said Ken Rodi, CEO. “Puroflux is a well-known and respected brand with a great reputation in the HVAC and commercial cooling space. The company has established a strong global sales network with high quality products, and we are looking forward to working with Dennis Jamison, President of Puroflux, and his existing team to expand their core markets.” Puroflux will become part of PURGO’s Flow Innovative Solutions (FIS) platform, which has grown to become a leader in water filtration and flow components within commercial, industrial, ground water, irrigation, and municipal markets.

Dennis Jamison, added “The entire team has worked hard to establish Puroflux as a leading provider of filtration and controls products to the commercial HVAC and process cooling industry. Finding the right strategic buyer who knows our markets and products was critical and I am excited for this new chapter for the business.”

ZwitterCo Launches Evolution Membranes, Transforming Dairy and Food Processing Efficiency

ZwitterCo, a global leader in membrane solutions for challenging liquid separations, has announced the commercial release of its Evolution membrane product family. These next-generation membranes are engineered to help food, dairy, and biotech processors increase productivity, reduce cleaning costs, and advance sustainability objectives—all without requiring changes to existing systems.

In dairy and food processing, every minute counts, but lengthy daily cleanings can consume valuable production time and significantly increase chemical consumption and water demand. Evolution membranes, built with ZwitterCo’s patented zwitterionic chemistry, are anti-fouling and fully recover performance with a simplified cleaning program. This enables processors to clean faster, use fewer chemicals, and reclaim over an hour per day for additional production or other high-value tasks.

Available in an ultrafiltration membrane for protein concentration (PCM), superfiltration (SF), and reverse osmosis (RO) membrane configurations, Evolution membranes are one-for-one replacements for conventional sanitary spiral membranes. They install easily in existing systems with no hardware changes needed to experience lower operational costs and time savings.

Thermo Fisher Scientific Completes Acquisition of Solventum’s Purification and Filtration Business

Thermo Fisher Scientific Inc. a global leader in science, announced the completion of its acquisition of the Purification & Filtration business of Solventum for $4.0 billion in cash. With the transaction complete, the business, which is now Thermo Fisher’s Filtration and Separation business, is part of the Life Sciences Solutions segment.

The transaction includes Solventum’s Purification & Filtration business serving Bioprocessing Filtration, Healthcare and Industrial Filtration, and Membranes. The business strengthens Thermo Fisher’s bioproduction offerings with advanced filtration technologies that improve quality and efficiency across upstream and downstream workflows. In addition, its robust industrial filtration and membrane solutions will expand our reach into industries requiring ultra-pure water, including battery, semiconductor and medical device manufacturing. For the full year 2025, the business is expected to generate approximately $750 million of revenue.

Metso’s Dewatering Technology Center in Finland Celebrates 10 Years

Metso celebrated the 10th anniversary of its Dewatering Technology Center (DTC) in Lappeenranta in the beginning of September. Since its establishment in 2015, the center has played a key role in advancing filtration and separation solutions development for the benefit of the global mining and processing industries.

Over the past decade, the Lappeenranta Dewatering Technology Center has grown into a unique hub of expertise, supporting customers with cutting-edge R&D, pilot testing, and process optimization. DTC works in close collaboration with Metso’s Filtration Technology Center, which specializes in filter manufacturing. Both facilities are located on the same site in Lappeenranta. The center’s work has contributed to more sustainable and efficient filtration practices across the industries – over 90% of Metso’s filters are part of the Metso Plus – Opens in a new window offering thanks to their energy-, emissions-, and water-efficiency.

“We’re proud to celebrate this milestone and grateful for our customers’ trust and our team’s commitment to innovation and exceptional customer service,” says Leena Tanttu, Director, Process and Testing of Filters at Metso. “Our Dewatering Technology Center offers comprehensive testing capabilities from bench scale to pilot, supporting efficient and sustainable flowsheet development, reflecting Metso’s long-term dedication to filtration technology.”

Transfilm Debuts IonClear

Transfilm Technology, a global leader in reverse osmosis and nanofiltration membrane research, development, and manufacturing, recently announced the launch of IonClear, a Silicon Valley-based company that supplies water filtration and resource recovery membranes for customers across North America and beyond. IonClear will serve American, Canadian and Mexican markets.

Transfilm Technology was established by a team of international scientists specializing in membrane research, development, and production for water filtration, reclamation, and reuse. The company operates a global network providing water purification solutions for markets around the world.

Cady Yu, CEO of Transfilm and IonClear, said: “The launch of IonClear in the United States marks an exciting new chapter for Transfilm. By combining our decades of scientific expertise with U.S.-based operations, we will be able to accelerate innovation, strengthen supply resilience, and deliver sustainable, high-performance water treatment solutions with closer-to-market innovations.”