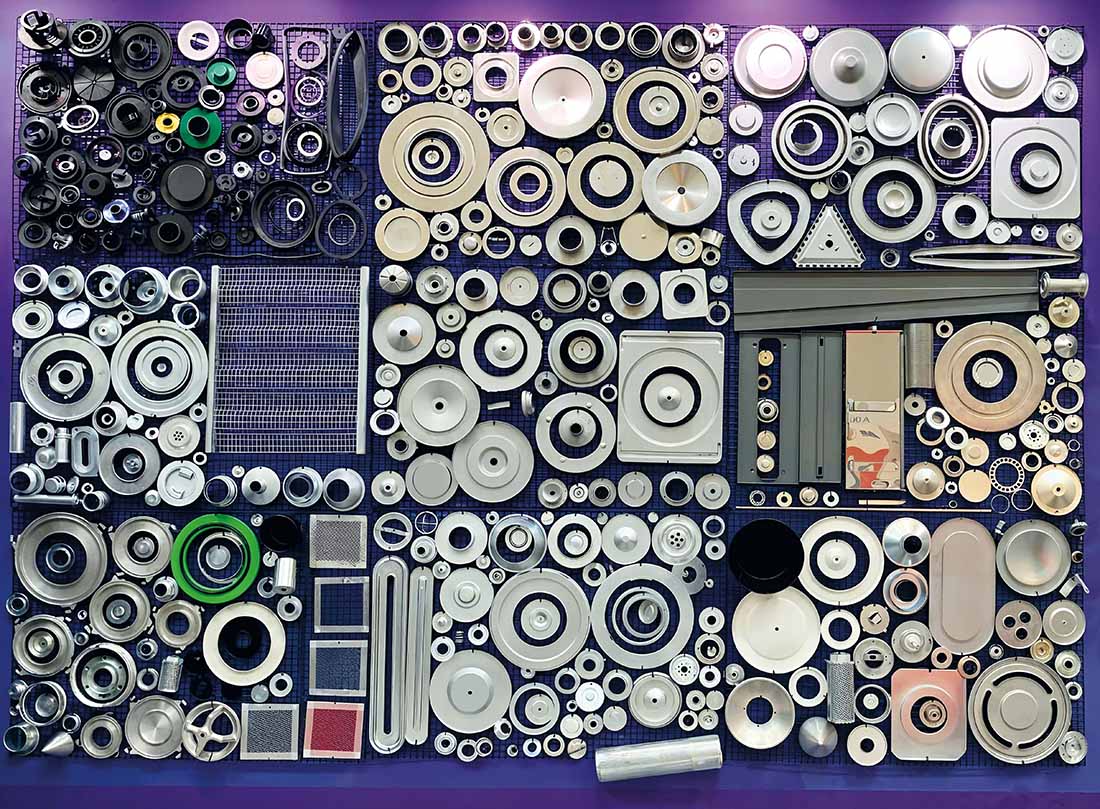

A2Z Filtration Specialities manufactures a large variety of end caps, components, and parts to suit the assembly of all types of filters. A2Z supplies products in sheet metal duly Stamped, Machined, Cast as well as Injection Molded parts. With a range of over 7,000-part numbers, we offer the broadest range of end caps on earth. Only the latest version of SolidWorks® is used to design all tooling. The ability to manufacture our own tooling with HAAS® CNC machines allow us to quickly turn around parts from concept to finished product in less than three weeks.

A2Z Supplies:

- End Caps – Stamped and supplied in Zinc, Tin, Nickel, Powder Coated. Also available in spun and fabricated.

- Expanded metal is available as cut-to-size sheets as per the specification of the customers or in coils in Galvanized steel, Stainless steel, Aluminum, and powder coated.

- Injection molded parts can be supplied in Glass-filled nylon (any grade), ABS, Polypropylene, Silicon, Polyester and Polycarbonate materials. The above components can be supplied in various grades materials including FDA-approved.

- CNC Machined Parts in materials such as Steel, Stainless Steel, Aluminum, Brass and Nylon.

- Synthetic Rubber Grommets, Gaskets, Sponge Rubber Air Filter Molded Sealing Rings (endless/jointless). Available in EPDM, Natural Rubber, Silicone among other materials as per requirement.

- Weld Mesh Cages of any size or configuration.

- Deep drawn housings and Threaded Top cover plates for spin-on filters.

- Perforated Sheets (Tin, Mild Steel, Zinc Plated or Paper Board)

- Panel Sets and Frames

A2Z Has the Infrastructure to Meet All Your Needs

- With a total covered area of nearly 200,000 square feet.

- Over 11 Solid workstations for Design.

- A tool room is spread over 50 thousand square feet and consists of 11 Haas ® CNC Machines over 13 mechanical lathes, surface grinders, milling machines. At any given time A2Z carries over 500 tons of various grades and thicknesses of stainless steel and steel materials.

- We have spot welding, projection welding, MIG welding, TIG welding, capacitor discharge projection welding and stud welding machines.

- Over 80 pneumatic power presses, hydraulic presses, double action presses with the range from 10 tons to 250 tons spread over 100,000 square feet. We can offer a quick turnaround of your orders.

- We also have multiple turret punch press and CNC hydraulic press brake machines to manufacture a large range of frames and punched parts.

- Five Dedicated High Speed Automated Expanded Metal Lines to produce expanded metal in various raw materials.

- State of the Art Inspection System, such as Carl Zeiss – CMM – Mitutoyo Contracer and various measuring instruments from Mitutoyo.

- In-house Sand Blasting facilities.

A2Z is the go-to supplier for all your component needs. A2Z also has the ability to provide supplies through 3rd party warehouses in North America.

For further information, please visit our website – www.a2zfiltration.com

or contact us at info@a2zfiltration.com