Tom Justice: Given the significant investments in new data centers, can you offer any projections on how this will affect the air filtration industry?

Nathaniel Nance: According to Stratview Research, the global data center air filtration market is expected to grow from $244 million USD (2024) to $417 million USD by 2031.

This presents a tremendous opportunity for air filtration manufacturers. And yet, I believe, in addition to greater sales, we have an even greater responsibility and obligation to “lead through innovation” for our customers, helping them anticipate their needs as their various technologies evolve.

This means greater demand for equipment, frames, and, of course, air filtration. However, the bigger questions are the ones yet to be asked: how will advanced air filtration support the volume and growing sophistication of data centers over the next half century? This is something we, as leading manufacturers, need to answer NOW.

Justice: Explain the typical filtration systems that are currently being used in data centers and why these products/systems were selected. What are the needs and opportunities for future filtration research?

Nance: Currently, standard installation is like any other filtration system with filter frames and filters. However, “standard” can mean a wide variation of installations. Typically, there is a diverse setup of inlet frames, locations, and applications with a large variation of filters used in those applications, depending on the degree of advanced filtration needed.

As the data center industry continues its dramatic growth, a keen eye will be needed on the vast resources and energy required to operate these centers, including a focus on reducing energy consumption, the disposal of exhausted equipment, and labor. In advanced filtration, the challenge is also our opportunity to optimize efficiency with minimal energy use and the lowest labor requirements. A tall order, however, one that data center managers should demand of their advanced air filtration partners.

Justice: Pocket filters (a.k.a. bag filters) have been on the decline in North America for close to two decades, with their market share shifting to other filtration options such as compact filters. Now, suddenly, we are seeing the revival of this product group, mainly driven by data centers. Why did pocket filters suddenly come back into favor in North America, and why for this application?

Nance: Pocket filters with either high-end synthetic or microglass provide a cost/benefit workhouse function for these applications. They have decent lifetime expectations without a prefilter, are

relatively lightweight, and have a high packing density for truckload shipments. They are also easily disposed.

There is also no regulating body that sets standards. Although the use of pocket filters has expanded, they are not the only solution, and in many cases, may not be the right solution for the setup.

Over time, as the data center industry becomes more regulated and best practices are created, leading air filtration manufacturers can help support new, innovative, and progressive solutions to keep costs low and efficiency high.

Justice: Currently, conventional filters are used to capture both gases and small particles that could damage servers. Could there be, or are there other cutting-edge technologies under development that might become a major disruptor for this industry?

Nance: Industry-wide, I believe there has been a renewed focus on filtration and clean air with new, innovative technologies constantly being developed.

The challenge is that the data center industry doesn’t have complete information to determine the real pain points that new filtration technologies can support.

The industry is also too segmented and lacks a clear understanding of the “right” level of cleanliness to support optimal production. Systems that can monitor corrosion and detect airborne gases will benefit data center operators by providing real-time data on the molecules in the environment, enabling them to be proactive about removing them.

We’re also working in a sector where everyone wants to develop a proprietary solution, while the end customer wants a commodity. As manufacturers, we need to step in and create bleeding-edge technology that is readily available, cost-effective, and meets the stringent needs of the client. It may be a tall task; however, the company that gets it right will win.

Justice: With so much attention focused on reducing landfill usage and lowering carbon footprints, do you see renewable, biodegradable, compostable, or incinerable solutions in filter design gaining favor with data center operators?

Nance: Without a regulatory standards-setting body in place, data center companies must take it upon themselves to focus on the total cost of ownership while reducing environmental impact.

It is a challenge and a balancing act. Sustainability is important to all companies; however, airflow efficiency and total cost of ownership still drive decisions. If the right balance can be struck, and products can be developed to achieve maximum sustainability objectives and meet strict performance, reliability, and cost thresholds, then we may be on to something.

The key is whether companies will find the worth in paying more for highly specialized products or can more commodity-oriented solutions be found.

Justice: How do you see the debate over air cooling versus direct liquid and immersion cooling affecting the projected demand for air filters?

Nance: If direct immersion cooling is utilized, it will reduce the overall number of filters needed for an installation; however, it will not eliminate the need to keep a clean space and protect the equipment.

There is already a significant installed base and consistent demand for direct cooling from traditional methods for the foreseeable future. I think it may change the growth trajectory, but not enough, since the capacity for either solution is insufficient to meet demand.

The industry also has a lot of principles thinking like any other industry, whereas if a solution is working and understood, the pain of going through a change will be slow to be adopted, barring external forces.

Justice: What future air filtration performance criteria are being demanded by data centers and can these goals be met?

Nance: This is an area where I am really excited to see how the industry changes over time. We have already seen shifts in some efficiency requirements; however, for the most part, this is still the wild west from the products/applications and setups standpoints.

We have no clear direction of where the industry is going, which makes it both exciting and difficult to predict the final outcomes.

However, like all emerging industries, the goal is always to reduce energy, lengthen service life, and minimize change-out schedules. With that is the drive for innovation and it is incumbent on advanced air filtration manufacturers to work with data centers to develop solutions that balance cost, efficiency, and energy savings with sustainability and profitability objectives.

To make all of this happen, we need consistent industry guidance. Without this, it will be extremely difficult to predict tomorrow’s requirements, as not only the growth rate but also the turnover in these facilities is incredibly high.

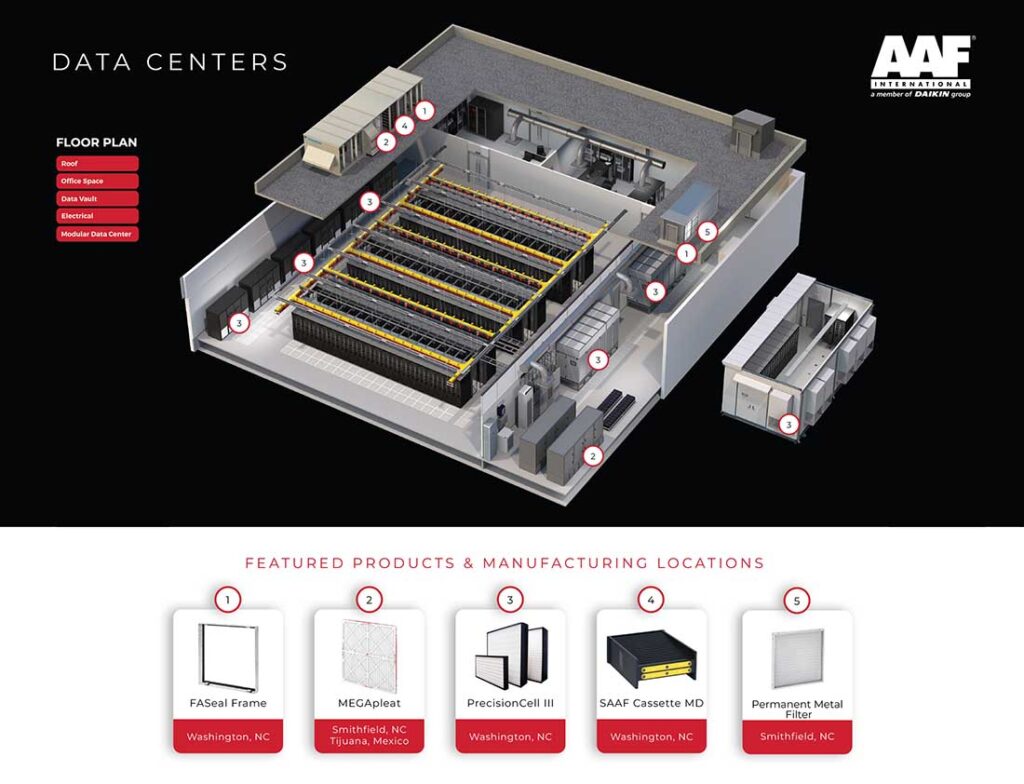

AAF Offers Options

Powerful IT infrastructures need clean air to help protect against downtime and data losses. Advanced filtration solutions are available to reduce airborne contaminants and maximize airflow, helping keep computers running as intended. The right systems can help shield against the risks of humidity, dust, and various airborne contaminants—even in coastal or polluted environments. AAF provides data centers with energy-efficient, high-performance solutions designed to help them stay competitive.

Data centers can require more energy than common commercial buildings. Fortunately, air filtration provides opportunities to improve energy efficiency while maintaining computer performance. AAF products, such as PrecisionCell and VariCel 2+, combine efficiency with low resistance, helping protect airflow; and, in many cases, systems such as the DriPak GX may provide all the filtration you need without supplemental filters.

Every time a filter is changed, it costs money and presents a risk of a shutdown. Reducing the number of unique filters needed—and how often they need to be changed—can improve your bottom line. AAF solutions help clients select systems that require fewer filters and fewer changeouts. The MEGApleat M9 filter is a cost-effective solution designed to be left in place for much longer than standard M8 filters. AAF can also design a system using permanent metal filters that may allow for the removal of an entire filtration stage.