Ecodesign is becoming more critical in the filtration industry. By considering the early stages of filter production, use, and subsequent disposal, companies can minimize waste, reduce energy consumption, and select more sustainable materials. This approach also presents new opportunities to enhance supply chains and develop innovative methods for delivering customer value. Let’s examine how product design choices impact recyclability and energy use, the growing importance of supply chain collaboration, and how forward-thinking companies are utilizing ecodesign to differentiate themselves in the marketplace. This includes business opportunities, new models, services, and market possibilities. Ultimately, ecodesign is not just a topic of compliance or cost; it is becoming a real competitive differentiator.

Sustainable engineering and Ecodesign are closely connected, but they focus on different levels. Sustainable engineering looks at the whole system and aims to reduce environmental impact across operations, products, processes, and infrastructure. It includes energy systems, production methods, and overall lifecycle management. On the other hand, Ecodesign focuses more directly on the product itself. It aims to reduce a product’s environmental footprint through wise material choices, modular design, energy-efficient use, and easier recycling or reuse. While both approaches support sustainability goals, we will focus mainly on ecodesign, the product-level design strategies that enable better environmental performance, cost efficiency, and business opportunities in filtration.

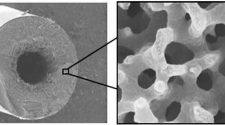

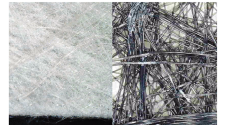

In Ecodesign, choosing and developing filtration media is crucial. Since the filter element is the core of the product’s function and environmental impact, early design choices, especially in raw materials and filtration media structure, have long-lasting effects across the entire lifecycle. Traditional filter media often rely on fossil-based polymers, which are efficient but not always recyclable or biodegradable. Ecodesign encourages shifting towards more sustainable options: bio-based polymers (PLA, PHA, PVOH), cellulose blends, or recycled fibres. The aim is to reduce dependency on virgin resources and improve end-of-life outcomes. Beyond raw material origin, the chemical design of the polymer down to the monomer level can support recyclability and lower toxicity. For example, using binders free from formaldehyde or switching to mono-material structures helps make the filter element easier to recycle or dispose of cleanly. Modular design is another key enabler. Filter housing or frames can be reused often, while only the media is replaced. This requires careful integration between media performance and structural support systems. Companies can facilitate recycling, reduce material waste, and develop take-back or reuse programs by designing elements for easy disassembly.

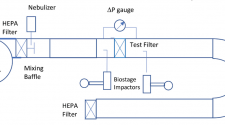

Optimizing energy use during filtration is crucial. Media with high dust-holding capacity and low-pressure drop can significantly lower energy consumption in HVAC or industrial systems. As energy use during the operational phase accounts for most of a filter’s environmental footprint, reducing flow resistance becomes not just a technical objective but an ecological necessity. In essence, filtration media development combines sustainable material selection, smart polymer chemistry, modular thinking, and lifecycle efficiency. This transforms the filter element from a disposable product into a strategic, value-adding component within a more circular and resource-efficient filtration system.

From a sustainability perspective, what happens to a filter after use is just as important as how it is made. Most contaminated filters, especially those used in industrial, automotive, or HVAC applications, are still treated as waste. They are often landfilled or incinerated, especially when made from mixed materials or containing hazardous particles. Ecodesign addresses this challenge by making filters easier to disassemble and sort. Using mono-material constructions improves recyclability. Reducing or eliminating glues, metal inserts, or toxic additives simplifies disposal. Reusing or refurbishing is a growing option for filters that cannot be easily recycled. Some systems allow the media to be replaced while the frame or housing is reused multiple times. In industrial applications, washable or cleanable filters can extend service life and reduce waste. Technical and scientific solutions can and need to be developed when recycling is not possible due to contamination. These include specialized decontamination processes, alternative separation technologies, or safe material recovery methods. Ultimately, ecodesign supports a shift from single-use, mixed-material filters to modular, recyclable, or regenerable components, enabling circular business models and reducing the environmental burden at the product’s end of life.

Ecodesign in filtration is not limited to product development; it requires close collaboration across the entire supply chain and manufacturing process. Companies must build cross-functional teams that include R&D, procurement, production, quality, sustainability, and logistics to make real progress. Material choices, for example, must align with supplier capabilities and environmental criteria and shared sustainability goals with upstream partners. Procurement teams must work together with design engineers to validate the availability, quality, and traceability. In manufacturing, sustainable design often involves process adjustments: minimizing production waste, reducing energy use, or enabling modular assembly. This can only succeed if engineering, production planning, and environmental management work together from the beginning. Cross-functional teams are also essential for implementing take-back schemes, reverse logistics, or recycling programs, areas that touch multiple departments. Lifecycle assessment (LCA) tools and sustainability metrics, such as carbon footprint metrics, must be integrated into decision-making across all stages. In short, ecodesign filtration is not the responsibility of one team. It requires an integrated, cross-functional approach across supply chains, R&D, and manufacturing to turn sustainable ideas into operational and commercial reality.

On a broader scale, we may observe the vertical integration of recycling or media regeneration units into filtration companies or the emergence of new service providers dedicated exclusively to end-of-life filter management. Cross-industry collaboration platforms, linking filter manufacturers, recyclers, and logistics providers, are another opportunity, especially for industrial and B2B markets. In summary, ecodesign enables a shift from selling filter units to offering sustainable solutions. It creates space for new services, partnerships, and even entirely new companies, placing sustainability at the core of future business strategies.

Ecodesign offers substantial potential for competitive differentiation in the filtration industry, but successfully introducing these products to the market requires more than technical innovation. The key challenge is market acceptance, especially in a sector where price, performance, and reliability have traditionally dominated purchasing decisions. Marketing ecodesigned filtration solutions means telling a transparent and credible story. Companies must explain how a more sustainable filter delivers environmental benefits and added value through a longer lifetime, lower energy use, or simplified disposal. This value proposition must be backed with facts: lifecycle cost savings, environmental certifications, or real application data. However, resistance remains. Many customers worry that sustainability means higher cost or lower performance. Others are unaware of how filters can impact energy use or waste streams. Education is key; companies must help customers understand that ecodesign does not mean compromise. A sustainable filter can reduce total cost of ownership (TCO), especially when energy and maintenance costs are considered. Even minor price differences can become an obstacle in a highly competitive market. To overcome this, suppliers must focus on value-based communication and offer clear comparisons showing operational savings over time.

Another strategy is segmentation. High-performance or premium product lines can introduce ecodesigned options where customers are more open to innovation. Fleet operators, cleanroom facilities, or ESG-driven companies may actively look for sustainable alternatives and be willing to pay for them. Once scale increases, these same technologies can become viable for cost-sensitive markets. Scale and volume effects are essential.

As global demand for sustainable products increases, economies of scale will help lower prices. Supply chains will adapt, and what is now a niche solution can become the industry norm. Brand differentiation is another opportunity. A company with a strong sustainability profile can position itself as a partner for customers facing pressure to meet ESG goals or reduce emissions. Ecodesign becomes a technical feature and part of a broader brand strategy.

As more filtration products are marketed as “eco” or “sustainable,” the risk of greenwashing increases. Customers and regulators expect explicit, verifiable claims. Certifications like ISO 14001, Cradle to Cradle, or third-party Environmental Product Declarations (EPDs) help prove that ecodesign is more than just marketing. Transparent reporting of lifecycle data, recycled content, or carbon footprint is becoming essential, especially for B2B buyers working toward ESG or supply chain goals. Marketing must be based on facts, not slogans. Companies should publish verified data, use recognised labels, and align with frameworks such as CSRD. From my experience, nonwoven and raw material suppliers in markets like hygiene, medical, automotive or geotextiles are already more advanced in automated carbon footprint reporting, especially for Scope 3. The filtration industry can and should catch up quickly.

Upfront sustainable parameters in filtration design don’t necessarily translate into higher upfront costs. By prioritizing wise material choices, optimizing designs for durability, and incorporating features like disassembly and recyclability, eco-designed filters can match the cost of traditional solutions. As supply chains evolve and economies of scale kick in, these designs become increasingly efficient and affordable. More importantly, eco-design looks beyond initial expenses, focusing on lifecycle value: reduced reliance on raw materials, energy-efficient operation, extended service intervals, and streamlined disposal processes all deliver substantial savings. For instance, reusable components and simplified end-of-life handling offer cost-effective solutions while maintaining exceptional performance. With rising adoption and growing demand, manufacturers are pushed to scale production of sustainable materials and components, leading to further cost reductions and design advances. Integrating eco-design principles isn’t just a technical innovation; it’s a strategic imperative.