In the dynamic and global filtration industry, news and information is breaking on a daily basis. International Filtration News is tracking stories relevant to our industry from air and gas filtration to liquid filtration and the various end-uses for filtration technology. Here we will post news stories relevant to filtration and its downstream applications on an ongoing basis. Please check back for regular updates. If you have news that you feel should be added to this summary report, please email it to Ken Norberg: ken@filtnews.com

Most recent update: August 22, 2025

Grundfos Completes Newterra Acquisition

Danish company Grundfos, a global leader in advanced water solutions, has completed the acquisition of the Pittsburgh-based water and wastewater treatment solutions company Newterra.

The acquisition underlines Grundfos’ commitment in expanding its water treatment and wastewater solutions capabilities as well as Grundfos’ strategic ambition to grow its presence in the US and Canadian markets.

“The addition of Newterra is another important step to realize Grundfos’ ambition to become a global leader in water treatment,” said Inge Delobelle, EVP & Divisional CEO, Industry division, Grundfos, adding: “It enhances our ability to provide modular, efficient and scalable water and wastewater treatment systems to our customers both in the US and the rest of the world. With Newterra on board, we can offer more complete, energy- and water-efficient solutions to our customers, helping them treat, reduce and reuse water more effectively, offering one of the most comprehensive water treatment portfolios in the industry.”

Grundfos’ revenue surpassed USD five billion in 2024, and with the inclusion of Newterra, the company’s water treatment business will have more than 1,500 highly skilled employees across Europe and North America and revenues exceeding USD 350 million.

www.grundfos.comhttp://www.grundfos.com

INDA Adds Policy Expert to Government Affairs Team

INDA, the Association of the Nonwoven Fabrics Industry, announced that experienced policy expert Kevin Conroy has joined the association’s government and regulatory affairs staff as Senior Manager of Government and Regulatory Affairs.

Conroy brings extensive experience in government, politics, and public service to his new role at INDA. He most recently served on the staff of former Maryland Governor Larry Hogan, where he held multiple senior positions over the course of Hogan’s eight years in office, including Director, Chief of Staff, and Assistant Secretary of Agriculture for the State of Maryland.

“We are excited to welcome Kevin to the INDA team,” said INDA President Tony Fragnito, “his wealth of experience will expand our government and regulatory affairs impact at the state and federal levels while positioning INDA for even more proactive advocacy for the nonwovens sector.”

Conroy began his career on Capitol Hill in the office of Congressman Chris Shays before working for Congressman David Dreier and the House Rules Committee. He has managed numerous political campaigns at both the state and federal levels, building coalitions and executing successful strategies in competitive races.

“Kevin’s wealth of experience will allow us to hit the ground running on several issues important to the industry, including EPA rulemaking, state and federal PFAS and chemical regulations, and plastics,” added Wes Fisher, INDA Director of Government Affairs.

With a career spanning legislative, executive, and electoral arenas, Conroy brings a deep understanding of public policy, intergovernmental affairs, and political strategy to his new position at INDA. He will be working on the INDA team out of the greater Washington, D.C. area.

Aquaporin Achieves up to 20% Energy Savings in Singapore

Aquaporin has successfully completed the Living Lab Project to develop the world’s first biomimetic low-energy Aquaporin Inside® CLEAR membrane at demonstration scale. The membranes were installed at the Kranji NEWater Factory (KNF), operated by PUB, Singapore’s National Water Agency. After 12 months of continuous operation benchmarked against parallel concurrently operated trains with other commercial membranes, the Aquaporin Inside® CLEAR biomimetic membranes have achieved up to 20% energy savings for the energy-intensive reverse osmosis treatment stage, while consistently meeting the stringent water quality standards of NEWater. The demonstration project marks a major step forward in the potential use of biomimetic membrane technology for the NEWater treatment process in Singapore.

Dr. Gurdev Singh, PUB’s Chief Engineering & Technology Officer, commented, “At PUB, we recognize that the future of water management lies in meaningful collaborations. We actively seek to partner with industry players who share our vision of innovation and sustainability. By working hand-in-hand from the early stages of planning and conceptualization, to the deployment of innovative technologies, we can transform promising ideas into robust solutions that serve Singapore’s water needs whilst creating opportunities for growth in the water sector.”

Klaus Juhl Wulff, CFO of Aquaporin and CEO of Aquaporin Asia, added: “We are really proud of our work in the Living Lab Project. Achieving energy savings of this magnitude, while maintaining consistent water quality during the NEWater treatment process, underscores the real-world application and positive impact of our biomimetic technology. PUB has been an exceptional partner, and this outcome is a testament to what we can accomplish together through a shared vision.”

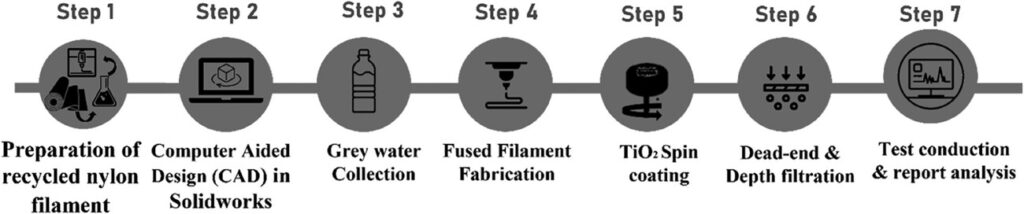

3D printed Filter Research Removes up to 85% of Greywater Pollutants

Researchers from Khulna University of Engineering and Technology (KUET) have developed a 3D printed honeycomb filter made to treat greywater from domestic sources.

The filter was produced on an Ultimaker FFF 3D printer, using virgin nylon filament blended with recycled material obtained by depolymerizing discarded nylon fabric, then coated with titanium dioxide nanoparticles. Nylon was selected for its chemical resistance, strength, and durability under repeated exposure to wastewater, making it more suitable than other common 3D printing materials such as PLA, ABS, or PETG.

Led by Sumit Kanti Saha from the Department of Textile Engineering, the project also saw contributions from Jashore University of Science and Technology. Published in Micro & Nano Letters, the work explores a low-cost, reusable option for non-potable water applications. While the results are promising, the team notes that further refinement is needed before the design could meet drinking water standards.

ietresearch.onlinelibrary.wiley.com

DuPont Membrane Technology Deployed in New Zealand

In collaboration with the Waikato District Council, Watercare, a public water utility in New Zealand has selected DuPont™ MemPulse™ membrane bioreactor (MBR) and OxyMem™ membrane aerated bioreactor (MABR) technology for a new 6.0 MLD wastewater treatment plant to serve the community of Raglan in the District of Waikato in New Zealand. This will be the first deployment of OxyMem™ MABR modules in the country—marking a significant milestone in the adoption of advanced wastewater treatment technologies in New Zealand.

In addition to enabling greater automation and reducing on-site personnel requirements, this multi-tech modular solution can provide compliance with New Zealand’s stringent discharge regulations and provide additional treatment capacity to future-proof the plant.

Raglan’s existing wastewater treatment plant combines an oxidation pond system with ultra-violet (UV) treatment before the treated wastewater is discharged into the sea on the outgoing tide. The treatment upgrade to MemPulse™ MBR and OxyMem™ MABR is the first step in removing the connection to the harbor. The clear water permeate discharge from the new treatment plant has helped gain support for a regenerated land-based discharge.

The decision to combine MemPulse™ MBR, which can provide the plant with high quality effluent, with OxyMem™ MABR will help Watercare achieve a lower total nitrogen concentration, making this community preference for land discharge viable.

Atlas-SSI Expands Capabilities with Acquisition of WTR Engineering

Atlas-SSI, Inc., North America’s premier provider of water management solutions, announced the strategic acquisition of WTR® Engineering, a trusted leader with over 100 years of expertise in mechanical water filtration. This acquisition enhances Atlas-SSI’s ability to provide comprehensive and robust water management solutions across diverse industries, including municipal, industrial, utility, and commercial sectors.

WTR Engineering is widely recognized for its expertise in identifying and solving complex water filtration issues, such as raw water intakes for industrial plants, condenser protection for power plants, and headworks challenges in sewage treatment facilities. The company’s experienced team specializes in providing economical, reliable, and customized equipment solutions, from initial greenfield project concepts to upgrades and turnkey installations.

Atlas-SSI will leverage WTR’s deep technical knowledge and proven track record to enhance its product offerings, including the Talon Rake®, traveling water screens, fish-friendly screens, debris handling equipment, wastewater headworks, and stormwater management systems. Additionally, this acquisition provides Atlas-SSI with enhanced capabilities, further solidifying its role as an industry leader in sustainable water management.

Italian Pump Manufacturer to Become Part of Atlas Copco Group

CRI-MAN S.p.A., an Italian pump manufacturer, will become part of Atlas Copco Group.

CRI-MAN was founded in 2000 and is located in Correggio, Italy. As part of the acquisition 85 employees will join Atlas Copco Group.

The company manufactures and sells chopper pumps, separators, and mixers for anaerobic flow, processing slurry in biogas and domestic and industrial wastewater treatment plants. Main customers can be found within the biogas and wastewater industries.

“We are very pleased to welcome CRI-MAN to Atlas Copco Group. With this acquisition we are further adding complementary technology to our existing industrial pump portfolio which will benefit our current customers and provide additional opportunities for growth”, said Andrew Walker, Business Area President Power Technique.

The purchase price is not disclosed. In 2024 the company had revenues of approximately 30M Euro.

The acquisition is subject to regulatory approval and is expected to close during the fourth quarter 2025. The company will become part of the Industrial Flow division within the Power Technique Business Area.

Centrisys/CNP Opens New 70,000-Square-Foot Building in Wisconsin

Centrisys/CNP, a leading North American manufacturer of decanter centrifuges and advanced biosolids treatment technologies, recently celebrated the ribbon cutting of a new 70,000-square-foot facility on its Kenosha campus. Known as “Building 4,” the addition increases Centrisys/CNP’s total footprint to approximately 300,000 square feet and represents a significant investment in U.S.-based manufacturing, advanced service capabilities, and the company’s long-term growth strategy.

The expanded space supports Centrisys/CNP’s production and repair of its largest centrifuges to date, while also providing dedicated space for aftermarket services and its growing rental fleet support. As utilities and industrial clients shift toward larger-scale systems, the facility is designed to help meet increasing demand with improved turnaround times, greater in-house capacity, and enhanced customer support.

“This expansion reflects both the momentum of our business and our commitment to building solutions here in the U.S.,” said Michael Kopper, CEO and Founder of Centrisys/CNP. “With new technologies, additional manufacturing space, and increased service capabilities, we’re in a strong position to support larger projects and continue providing the high level of responsiveness our partners expect.”

Asahi Kasei Expands Planova™ Production with New Spinning Plant

Asahi Kasei Life Science, a division of diversified global manufacturer Asahi Kasei, announced plans to construct a new spinning plant for its Planova™ virus removal filters in Nobeoka City, Miyazaki, Japan. The new facility will be the company’s fourth spinning plant for hollow-fiber cellulose membrane filters. Construction is scheduled to begin in July 2026, with operations starting in January 2030. The initiative, backed by a grant from Japan’s Ministry of Economy, Trade, and Industry (METI), aligns with Asahi Kasei’s recently announced medium-term management plan “Trailblaze Together,” which positions the Life Science business as a key driver of future growth.

With strong market growth projected to continue, Planova™ is well-positioned as one of the global leaders in virus filtration for plasma-derived therapeutics and biologics. The new plant will significantly expand the company’s production capacity in response to accelerating global demand, focusing on the production of Planova™ filters S20N, 15N, 20N, 35N, and 75N. The planned capacity expansion represents a strategic investment to capture future demand, enhance global supply chain resilience, and reinforce the position of Planova™ in the high-value bioprocessing market.