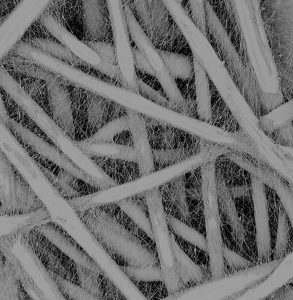

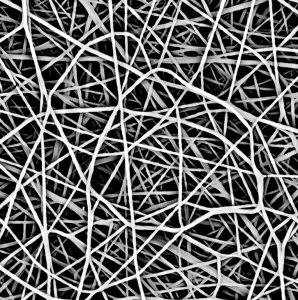

NXTNANO is driven by a commitment to deliver exceptional, industry-leading nanofiber products on an unprecedented production scale. Our industry leadership is sustained through a novel, in-house developed HYPR Spinning process. NXTNANO mass produces nanofibers from a wide variety of polymers such as PU, PVDF, PAN, PES, and PI. This versatility combined with a unique ability to simultaneously spin multiple polymers provides unprecedented flexibility.

Today NXTNANO products encompass a range of nanofiber media, from very light surface coatings all the way up to full membranes for the apparel and microfiltration industries. In a nutshell, NXTNANO brings commercial viability to nanofiber products across the entire filtration spectrum.

Our capabilities

NXTNANO’s HYPR spinning lines are roll-to-roll production with an annual capacity for high-efficiency nanofiber air filtration media in excess of 60 million sq. meters. The HYPR spinning process is also very flexible in the types of media that can be processed: Cellulose Blends, Spunbonds, Felts, Wet Laid, Synthetics, Ceramics (to name a few).

Besides enhancing existing media with nanofiber, NXTNANO is uniquely positioned to produce fully stand-alone 100% nanofiber membranes. The membranes are available in basis weights from 2-15 GSM, and deliver consistent, controllable pore sizes.

Common applications for NXTNANO’s air filter media include:

- Gas turbine inlet filters;

- Industrial cartridge filters;

- HVAC pocket & pleated filters;

- Automotive air Intake; and

- Face Masks

The nanofiber membranes operate in three distinct categories:

- Micro-venting;

- Micro-filtration; and

- Apparel

In Micro-filtration the nFLUX nanofiber membranes deliver more than a 100% increase in flux for a given pore size compared to a traditional cast membrane of the same pore size. nVENT nanofiber micro-venting media offer a tight pore size distribution while being readily compoundable as hydrophobic/oleophobic, hydrophilic, or even antimicrobial. To further support our nanofiber customers NXTNANO also has in-house slitting of materials across two slitters, or contract pleating of media via two rotary pleaters, and a blade pleater with full mini-pleat capability.

This content is sponsored by NXTNANO.