Air Techniques International (ATI) is a global leader in the design and manufacture of specialized test equipment for HEPA filters, media, filter cartridges, respirators, and protective masks. Recently ATI is making a name for itself in the mask testing industry where its automated filter tester has brought industry-leading accuracy and efficiency to validation testing performed by leading filter media, cartridge and respirator mask manufacturers.

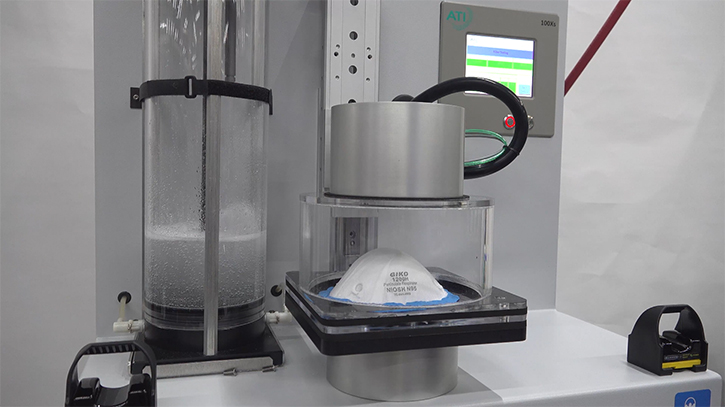

The 100X Automated Filter Tester combines ATI’s core technologies into a single, compact test unit to test and validate filter media, cartridges, and masks in production, quality control, and R&D applications. In production environments, the 100X provides accurate and repeatable results while minimizing production downtime and maximizing throughput. In QC/R&D labs, the 100X provides the same accurate results while offering portability and quiet operation.

Technology highlights

The 100X features unique technologies that improve testing accuracy and minimize service and maintenance costs. The 100X incorporates an integrated flow controller that not only maintains a constant flow rate as the media or mask is loaded with test aerosol, but also during temperature and humidity fluctuations throughout the day. The 100X samples 100% of the challenge aerosol ensuring accurate results and reducing potential sampling errors inherent in legacy designs; and with fewer, more robust parts, service costs are reduced while uptime is increased.

The 100X has played a key role during the COVID-19 pandemic to perform the sodium chloride (NaCl) aerosol challenge required to test and validate the filtration efficiency of N95/FFP2,3/KN95 style respirator masks. As the COVID-19 pandemic began to spread in early 2020, demand for respirator masks far exceeded supply. With this increased demand came the need for test equipment to validate the filter media and masks to the relevant regional standards such as NIOSH 42 CFR Part 84, GB 2626, EN 13274-7, etc. ATI has experienced an unprecedented surge in requests from filter media and respirator mask manufacturers seeking its technology to perform the critical tests required by global standards when validating respirator masks and high-efficiency filtration media.

Key capabilities

- 100% Sampling Aerosol Detection System – An essential requirement of an automated filter tester is its ability to accurately test filter media for resistance and penetration. Precise, repeatable results are vital to minimizing false failures while at the same time not failing product that is within spec. ATI’s 100% Sampling Aerosol Detection System is designed to produce accurate results and can test a wide range of HEPA and ULPA grade filters, up to 99.9995% efficiency.

- Custom test fixtures – ATI has decades of experience designing custom test fixtures to allow for testing of unique masks or filtration cartridges. ATI provides engineering, manufacturing and verification services to ensure that the custom test fixture meets your unique needs.

- Fewer parts, easy access to key components – Maintenance can be a hidden cost for any piece of equipment and automated filter testers are no different. Since automated filter testers are central to quality control, R&D, and production functions it’s extremely important that the equipment performs at a high-level and runs with maximum uptime. And when routine maintenance is needed it’s important to minimize downtime so that production yields remain high. The 100X automated filter tester is designed with fewer parts than most conventional filter testers and the critical components are easy to access when cleaning and performing maintenance.

- Integrated flow controller – An integrated flow controller maintains the desired flow rate as the mask or media is loaded with aerosol and during temperature and humidity fluctuations throughout the day. This feature gives the user confidence that the data will not vary whether the measurement is taken in the morning, afternoon, or evening.

Visit Air Techniques International at Filtration & Separation Asia: Booth C18