September/October 2014 | Volume 33, No. 5

Straining and sludge/process dewatering in industry is normally accomplished by a variety of intake water strainers, by sand filters and by filter presses and automatic pressure filters, as well as centrifuges, belt presses and screw presses. General wastewater removal techniques for industrial streams along with specific nuclear plant wastewater treatments and sintered metal filters are also discussed in this article. This paper will attempt to present an overview of the SLS technologies where sieves, strainers and reusable filters are used in all industries, including nuclear power.

STRAINERS

Strainers are primarily used for intake waters to remove debris, silt, sand, etc., from rivers, lakes, etc. They generally are backwashed or brush-cleaned by a variety of techniques, but most have greater than 25-micron removal ratings. They generally are used for high flows and very low solids loading to protect operating equipment. Other methods of cleaning the strainer screens or wedge-wire are vibration, scraping, rotation and even removal from the flow stream and external cleaning (i.e., bar screens as used in municipal wastewater industry). Even simple manual basket strainers can be considered since dual units are generally provided for switching to the clean strainer, removal of the dirty one, washing it to remove debris, and reinstallation. Automated strainers can be used to eliminate the manual cleaning operation, but these use some of the filtrate stream to remove the collected debris, which then needs to be further processed and disposed of.

MICROSCREENS

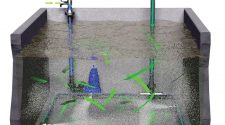

This category involves screens down to about 10 microns for high flow, non-sticky, low solids straining coupled with various devices to clean the screens while continuing to operate [i.e., Ronningen-Petter (Eaton) Russell-Finex, Amiad, Boll, Mahle, Spencer, Miller-Leaman, etc.]. These have found widespread use for cooling towers, food processing plants, municipal and power plants, papermaking, river water debris removal, irrigation systems, etc. The Russell-Finex ECO strainer utilizes a spiral wiping assembly that continuously wipes the entire inner surface of the screen to positively drive away oversized particles and maintain flow rate and low differential pressure. Ronningen-Petter (Eaton) uses sequential backwashing in their standard filter and a Teflon┬« wiper blade in their new DCF filter. Amiad utilizes a differential pressure switch to activate a cleaning cycle, which consists of a rotating suction scanner with nozzles about 1/8″ from the inside screen where the particles are trapped. The influent pressure and the rotating nozzle scanner create backflow through the nozzles. This cleaning typically takes about 40 seconds. Sandwiched screen layers are used to obtain the lower micron ratings. Other manufacturers use a variety of techniques, primarily cleaning brushes. Nevertheless, these pressure-driven micro screens have made significant inroads into the solid/liquid separation field in all industries. Another micro screen device utilizing perlite filter aid (Neptune-Benson) has found widespread use in the municipal swimming pool and aquarium markets.

BACKWASH FILTERS

This category usually involves cake filtration onto leaves, plates or tubes along with added filter aid (for both precoating the various media as well as “body-feeding” to enhance the filtration rate and performance). Feed slurry solids loading is usually low (i.e., clarification), but can be high in isolated cases. Media generally tend to be woven cloths, or stainless steel meshes, but micron-rated papers are used particularly in horizontal plate filters. Goretex┬« and Tyvek┬« can also be used here since it is well protected in these filters, is reused and provides for excellent cake release. Occasionally depth-type pads are used without filter aid in horizontal plate filters for clarification applications, but then the media has to be replaced manually on a periodic basis. Suitable plate filter vendors are Industrial Filter, U.S. Filter, Sparkler, Funda, Ertel, etc. In general, these backwash filters (excluding those with media pads) are sluiced clean of accumulated debris plus filter aid by sluicing nozzles to form a high-solids ~1% backwash for further dewatering/disposal. Occasionally, the vessel contents are purged with air or nitrogen and the cake partially dewatered. The dewatered cake can then be either blown-back or the leaves spun to remove the partially dried cake. Blowback filters are made by Industrial Filter, Pall, Mott, Croll-Reynolds, Vacco, U.S. Filter, Goslin, R.P. Adams, Schenk Funda, Baker Process, etc. Micron removals with these filters are generally from 0.1 to 10 microns.

TUBULAR BLOWBACK FILTERS

This category involves liquid blowback of accumulated solids similar to the concept used in an air-cleaning baghouse. The accumulated solid cake (with or without filter aid) is simply “bumped” off the media by a short, few second rapid, liquid flow reversal and then allowed to settle in the vessel to form a thickened sludge. This concept was successfully applied by W.L. Gore & Associates in their Gore back pulse filter. Mott employs a similar concept for catalyst recovery in the oil industry as well as condensate polishing in the nuclear power industry. The advantages of these blowback filters is that tight 0.2-3.0 micron media are used to simultaneously clarify the liquid stream to a very high quality and produce an ~5% solid sludge for disposal/recycle. Most importantly, the media is reused and usually lasts between one and six months before the socks require replacement. Recently, DuPont introduced their low-cost SoloFlo™ sock based on Tyvek technology. The Mott tubes are made of porous stainless steel and have been known to last up to 20 years but periodic cleaning with acids or detergents is usually required. In addition, the Mott design utilizes a patented inside-out filtration, which prevents cake bridging across the tubes (and possible tube breakage during blowback). It also permits in-situ cake drying and easier wet filter cake discharge as a concentrated sludge. These Mott filters have found widespread use in the nuclear power/waste industries. Another outside-in design is manufactured by DrM but it utilizes cloth socks over a unique support tube and can withstand higher pressure.

BACKWASHING MEDIA FILTERS

This category encompasses the entire array of so-called “sand filters” (or deep-bed filters) used in the municipal water and wastewater, oil refinery and production, power generation, and industrial process water applications. They are ubiquitous and are used in a variety of applications and comprise many designs from automated to fully continuous. They can utilize sand, garnet, anthracite coal, walnut shells, plastic beads, ceramic beads, etc., as media; and even multi-media like the combined anthracite coal/sand filters used in many industrial applications. They can even remove emulsified oil from industrial and power generation effluents and oil refinery wastewaters. Sand filters typically remove particles down to about 5 microns, but coagulation/flocculation can even remove sub-micron particles and colloids. Solids loading are usually limited to less than about 1000 ppm, but certain designs can handle up to about 2000 ppm. A recent breakthrough in sand filter design incorporates a modular design for improved removal efficiency at even higher loadings (Filtersure).

Flow can be both down or up through the bed, but down flow is usually practiced. Backwashing is usually done with ~20gpm/ft2 upflow flushing, but an air scour can also be used to improve particle removal. Agitation and/or pumping of the sand bed is also sometimes done like in the continuous Parkson Dynasand™ or Arus Stratasand™ designs, but the sand has to be of uniform size to prevent sand segregation. Parkson also has a patented D2 design with two Dynasands in series for giardia and cryptosporidium removal from drinking water. The novel Filtersure modular design mentioned above can even backwash each individual module separately (of 5 normally used) and continue operation throughout the other modules. Thus, one should note that these backwashing media filters (or sand filters) incorporate a wide variety of designs and are used throughout all industries.

BACKWASHING CARTRIDGE FILTERS

These are a relatively new technology developed by the cartridge filter suppliers to offer an alternative to the general high cost of disposable cartridges (both initial cost and disposal). They are simply specially prepared pleated cartridges that attempt to develop a cake on the media surface, which is then backwashed at high reverse flow to remove accumulated cake and clean the media. Typically, 2-10 micron rated cartridges are used, but unfortunately, they do eventually foul and need to be replaced. Leading suppliers are Pall, Parker, Hoffman, etc.

FILTER PRESSES

Filter presses have had a tremendous resurgence in the past 15-20 years with the advent of polypropylene (PP) recessed chamber and membrane (diaphragm) plates. The old, manual plate-and-frame design is now a relic of the past, especially since most plants are becoming more automated. In addition, they are generally simpler mechanically and do not have many moving parts (and those that do are low speed).

The first major development was the PP recessed chamber plate (with staybosses to prevent plate breakage), which allowed plate shifting to be automatically done, because the cakes formed between adjacent plate recesses would fall out by gravity. Of course, careful filter cloth selection and maintenance are necessary to assure good cake release. Recent advancement in cake release automation has been introduced in Europe but the most promising in my view is the Netzsch cake-scraper design.

The next development was the now standard 225-psig (15 bar) design, which permitted high pressure feed pumps to be used for added cake moisture removal (e.g., Abel, Feluwa, Geho, etc.). These high-pressure pumps were maintenance prone, but today sophisticated pumps are available, which are much more reliable. Other disadvantages of this 225-psig “standard recessed” design are its long filtration cycle necessary to obtain dry, firm cakes and the absolute necessity to have sufficient solids to fill the chambers completely (otherwise sloppy cakes will occur).

Flexible membranes (or in reality, non-permeable diaphragms), which are an integral part of the plates, are inflated with either air or water (also up to 15 bar) to compress the cakes. Today, plate designs are available to 30-bar or 450-psig, but they are primarily used in Europe. These membrane plates assure dry, firm cakes regardless of fill volume (provided at least about 1/3 of the chamber is filled). They accomplish the following: (1) only a low pressure, inexpensive feed pump is required (e.g., centrifugal, Abel EM, single-stage progressive cavity, Discflo, etc.); (2) a much shorter press feed cycle, thus, increasing capacity; (3) eliminates cake thixotrophy; and (4) most importantly, permit thorough cake washing to remove cake impurities or to recover more of the valuable mother liquor. In addition, these membrane plate presses improve cake release and produce drier cakes. Most recent dewatering/washing applications have utilized these membrane plate presses quite successfully for both products and wastes. Membrane presses have been used to dewater/wash fine pigments to exceptionally low salt ion content (replaced a ten-stage repulping operation, for example).

The key to these membrane presses is the PP membrane plate, which are separately manufactured by German plate companies, independent of the filter press manufacturers. The two leading vendors are Lenser and Klinkau, which almost exclusively supply the USA with PP plates. Other vendors (Hoesch, JVK, etc.) supply rubber membrane plates with a PP body, which are finding more use today because these membranes can be replaced when broken. In contrast, the PP membrane plates are an integrally molded part so that the entire plate has to be discarded in the event of membrane failure. Nevertheless, these one-piece molded PP membrane plates typically last years under normal operation. Recently, both Lenser and Klinkau have developed replaceable PP membrane plates, which have been widely accepted by the industry (e.g., to eliminate the objection of discarding the entire plate). Klinkau’s new “Overhanging” detachable PP membrane plates, which are generally more costly, have 8-12% less cake volume per plate. Klinkau has also developed a corner-feed membrane plate, which eliminates the wash-water channeling and plate failures that occurred with the earlier center-feed plates, which had 4 to 8 staybosses for support. These staybosses and the center-feed eye are exactly where channeling occurs and where most membrane failures have occurred. Most membrane plate presses in the past 20 years incorporate corner-feed plates without staybosses (up to the 1200mm size only while the 1500mm size has only one center stayboss). This corner-feed design results in much better cake washing, slightly drier cakes, better cake release, and fewer failures due to membrane inflexibility at the staybosses.

In short, filter presses are a versatile pressure filter for producing dry solids suitable for disposal by either incineration or landfilling; and are used throughout all industries. And they are reusable filters since their cloths usually last 6 months or longer and the various filter press designs can incorporate automatic cloth washers to maintain filtration capacity as well as long filter cloth life.

OTHER DEVICES

The three devices – continuous centrifuges, belt presses and screw presses, are ubiquitous in the municipal sewage sludge and water treatment industries. The centrifuge primarily used is the solid-bowl (or decanter), which uses no filter media but dewaters against a solid wall. Belt presses use open cloths that are washed every return cycle, while screw presses use metal screens that are periodically washed with sprays. Nevertheless, these devices can be considered recleanable/reusable filters.

AUTOMATIC PRESSURE FILTERS

Automatic Pressure Filters (APFs) have long been used in the machine tool coolant industry for tramp solids removal and recycling of expensive coolants. They are extensively used in the aluminum can and foil industries as well. They are also far simpler than the traditional three-step process commonly used for wastewater treatment (i.e., clarifier, overflow polishing sand filter, and underflow filter press). Today these versatile APFs can provide low-cost dewatering in a single step to produce dry cakes in an automatic unattended operation.

APF dewatering consists of horizontal plate(s) between, which is a sandwiched filter medium; pump pressure is used to force the slurry into the plate and through the medium upon which the cake forms. In concept, it is similar to the vertical filter presses (or automatic tower presses (ATPs) by Hoesch and Larox) with one key distinction, namely, APFs can use disposable filter media (and can use belts as well), much like a roll of toilet paper fed between the plates, where ATPs use a reusable cloth belt that is wound around rollers, must be tracked, and must be washed each cycle on its return. In addition, because of their design, ATPs filter on both sides of the belt whereas APFs filter in one direction: and ATPs operate up to 225 psig whereas APFs operate at 30-100 psig. As a consequence, ATPs are mainly used to dewater/wash products (i.e., mining concentrates, beet sugar, foodstuffs, etc.) whereas APFs are used primarily for wastes, machine tool coolants, aluminum can and foil manufacturing, and a variety of wastewater dewatering applications.

Somewhat similar developments to the ATPs, but in reality are high 15 bar pressure APFs, should be mentioned here. The first is the Filtra-Systems’ Verti-Press, which is a lower-cost simpler design, and can use either recleanable cloth belts or disposable media. The second is Pneumapress’ unique design, which uses compressed air to both compress and dry the cakes, and is much simpler and more economic than its ATP competitors, Larox and Hoesch. It has found wide acceptance in the mining, biofuel, and wastewater generation industries.

APFs are quite simple, especially when used with disposable filter media, since the accumulated cake and media is disposed of each cycle. As a result, belt washing is not required, cloth blinding is eliminated and cake release is assured. The spent media can be rewound for separate-disposal, dumped along with the cake, and can even be doctored, brushed or washed to remove residual cake debris. It can also be rewound back under the plates and reused until it blinds upon which it is discharged. A variety of media can be used depending on the application, but most importantly, its strength is unimportant since a base belt can be used for conveyance. Extreme flexibility in filter media choice is basically why APFs can be used in a variety of applications, particularly for various wastewater applications. In addition, APFs can incorporate cake washing; can be completely enclosed for handling toxic or radioactive wastes; can utilize PLC control for complete unattended operation; incorporate automatic flushing capability for shutdowns; have complete safety interlocking; assure positive dry cake discharge; and can incorporate complete integrated auxiliaries, such as pumping systems, flow controls, filter aid systems, polymer flocculent systems, etc.

Five basic APF systems are available, namely, Filtra-System’s Verti-Press, J.R. Schneider’s aluminum can coolant and sludge filter as used for geothermal brines; Summit’s stacked coolant filter, Pneumapress’ high 15 bar pressure APF; and Oberlin’s APF. The Oberlin APF is better suited for low wastewater flows, whereas Schneider, Verti-Press and Summit units are better suited for larger volumes and flows where cake washing is required. The Oberlin APF system utilizes a single chamber design with filtration areas up to 50ft2, whereas Schneider, Verti-Press and Summit designs incorporate stacked filter chambers in a single unit with areas up to 1000 ft2.

The Pneumapress is simpler and lower in maintenance but is higher in cost. However, it has competed quite favorably with the Hoesch and Larox ATPs, but it is relatively new and will require market demands to dictate its applicability to wastewater dewatering.

Summarizing, APFs are very versatile and are used in a variety of industries.

CONCLUSION

This paper has attempted to address the various pressure filters, sieves, strainers, and other filter technologies that can be used in industry as recleanable/reusable filters. It discusses the primary pressure filters that can be used for both water intakes and wastewater discharges. Consequently, it should only be used as a guide since each application will be different.