The unique Viledon Honeycomb modules with activated carbon are now available in Europe

Thanks to a new technology, Freudenberg Filtration Technologies has set new standards in corrosion protection. Known as Viledon Honeycomb, the new modules and system solutions ensure operational security anywhere that process-related harmful corrosive gases occur and threaten sensitive electronic devices and equipment. Honeycomb system solutions are already being used successfully in America, where Freudenberg Filtration Technologies is the market leader in the US petrochemical industry. Now this innovative technology is also available in Europe.

All sorts of noxious gases, from hydrogen sulfide and sulfur oxides to ozone, cause corrosion in electronic components. The negative consequences include reduced process efficiency, additional maintenance costs, expensive repairs and unplanned downtime.

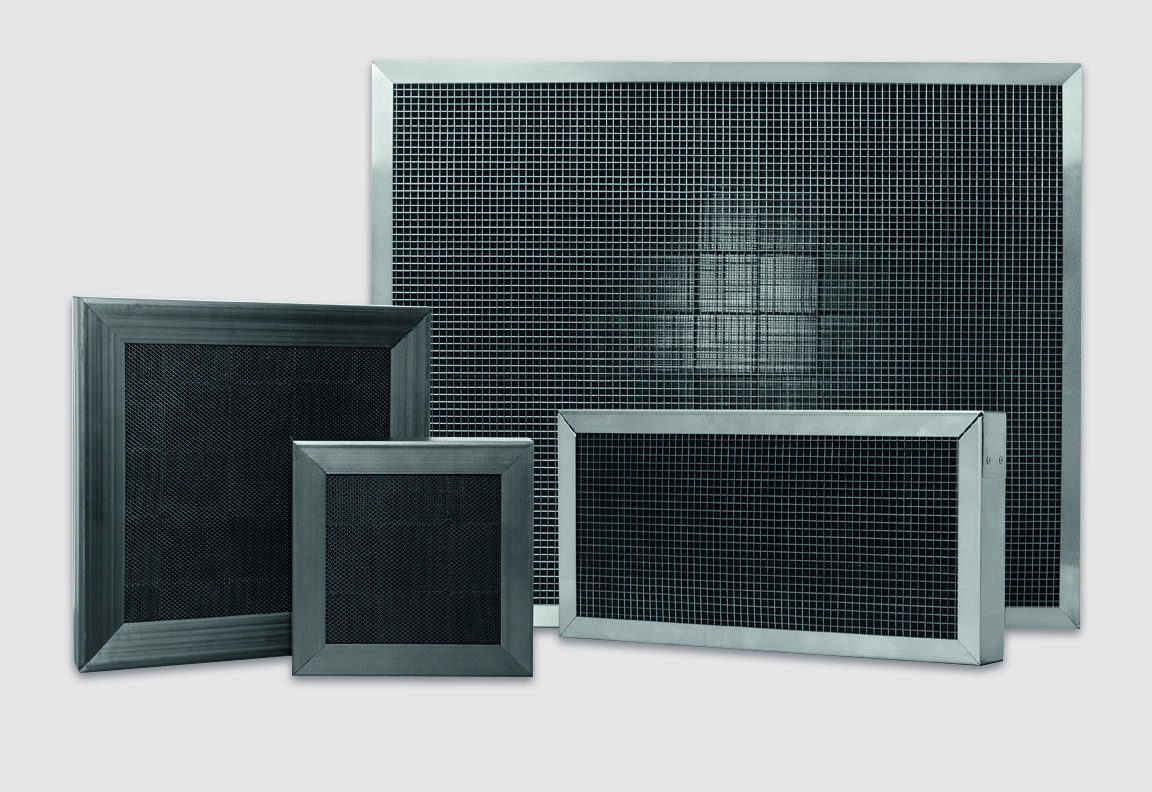

Tried and tested in gas phase filtration, Viledon ChemControl pellets reliably eliminate acidic pollutant gases from intake and recirculating air. Viledon Honeycomb modules complement this portfolio. Alongside their performance and reliability, they offer a number of other advantages. Pressure loss when air is flowing through the filters is extremely low, making them particularly economical and energy efficient. Reminiscent of a honeycomb structure, their compact form also saves space in very cramped conditions, such as on oilrigs. The modules are also particularly user-friendly, easy to install in standard filter housings and can be simply maintained without additional aids. Change intervals can be determined in advance, based on the environmental conditions. “With Viledon filterCair, we offer customers a fully customized service package that can include corrosion protection as well”, explained Dr. Ren├® Engelke, Market Segment Manager Gas Phase Filtration at Freudenberg Filtration Technologies.

The future of air cleaning

Viledon Honeycomb modules consist of channels arranged in parallel, through which the process air passes. Walls made of activated carbon powder separate the channels from each other. The walls are less than a millimeter thin and are held in shape by ceramic binders. The distance between carbon and process air is therefore minimal, allowing highly efficient filtration performance at high flow velocities.

This sophisticated structure points the way to the future of air cleaning. Following the company’s success in America, Freudenberg Filtration Technologies has now equipped well-known reference customers in Europe with Viledon Honeycomb modules and system solutions for the first time.

About Freudenberg Filtration Technologies

Freudenberg Filtration Technologies is one of the world’s leading manufacturers in high-performance and energy-efficient liquid and air filtration technology solutions. By improving the efficiency of industrial processes, conserving resources, and protecting people and the environment the solutions contribute to enhancing the quality of life. With its Viledon and micronAir global brands, Freudenberg Filtration Technologies offers customers innovative filter elements and systems for the energy, health, and transport (automotive, rail, marine, aviation) sectors, general ventilation and cleanroom technology, and for highly-specialized applications. In 2015, Freudenberg Filtration Technologies employed about 2,300 associates and generated sales of around Ôé¼ 394 million. www.freudenberg-filter.com

For more information, please visit www.freudenberg-filter.com