Porvair Filtration Group has achieved status as an accredited supplier to the Nuclear Power Corporation of India Limited (NPCIL), after qualifying and supplying its polymeric filter cartridges.

Initially being recognised as a supplier in 2013 to the Tarapur Atomic Power Station, Porvair was again invited to bid for a similar project at the Kakrapar Atomic Power Station (KAPP) and the Rajasthan Atomic Power Plant (RAPP) in 2017.

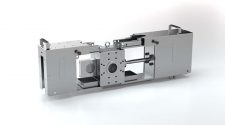

Porvair’s Microfil™ polymeric filter cartridges were selected for the filtration of cooling water in the plant’s moderator line. The installation of the filter was critical to prevent the build-up of radioactive particles in the system and consequentially the development of areas of high radioactivity, also known as hotspots.

As part of the qualification process, Porvair’s Microfil™ filter cartridges were tested in the presence of an independent witness from a leading regulatory body, in accordance with the NPCIL criteria to meet their Quality Assurance Plan.

This product testing confirmed the filter’s efficiency and compatibility with the process conditions encountered. The results demonstrated a significant safety margin that was above the recommended operating parameters of the process specifications.

In addition, tests confirmed the filter’s ability to resist the aggressive process conditions, including: high pH, high temperatures and deformation under pressure. What’s more, installation in heavy water applications has resulted in no reported degradation of the filter media due to radiation.

Working in Partnership

Working in partnership, Porvair’s dedicated test, development and laboratory teams offer a wide range of services to support customer requirements, from design and development through to product verification and performance evaluation.

In-house capabilities include filtration characterisation, environmental testing and analysis. Porvair Filtration Group has a policy of continuous improvement across all areas of the business; listening to customer’s requirements and working together to drive change.

Kevin Ward, Business Manager, Nuclear Services, stated: “We are delighted to be awarded accredited supplier status to the NPCIL, which is testimony to our tailored approach to problem solving. We are also pleased to be able to continue to build on our relationships within the Indian Nuclear Industry.

“Working alongside customers in order to help achieve performance requirements is a key feature of technical service offering.

“We are committed to providing the best products and services to our customers. It is only by forming multidisciplinary teams and working together, that we are able to design, engineer and validate the optimum solution according to end-user specification”.

MicrofilTM absolute rated pleated glass fiber cartridge filters

Porvair’s validated Microfil™ cartridge filters, manufactured in an ISO cleanroom, are constructed from robust glass fiber and polypropylene filtration layers, offering removal ratings from 0.5 to 5 micron absolute in a single pass test. Their epoxy-bonded construction ensures high dirt holding capacity and excellent chemical compatibility.

These cartridges display a natural, positive electrostatic charge, which when used in aqueous solutions, results in the enhanced removal of submicronic particles, smaller than the designated micron rating.

Porvair Filtration Group

Porvair Filtration Group is an international leader in the development and supply of high performance, innovative materials and solutions for applications in filtration and separation.

Porvair manufactures in both the UK and USA and has an extensive network of sales offices and distribution channels throughout the world. Its expertise in a wide range of media and the dedication of its design, manufacturing, sales, test and research teams ensure it is at the forefront of filtration technology.

For over 50 years Porvair has delivered world class performance to the most demanding of environments, including Aerospace and Defence, Nuclear, Energy, Chemical Process, Industrial Process and Water Treatment.