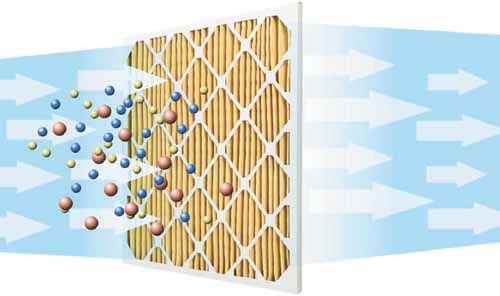

When it comes to designing air filters for today’s commercial HVAC systems, filter manufacturers have a variety of choices in filter media. Some manufacturers choose to produce lower-efficiency panel filters, which are typically made of fiberglass and allow for the capture of only the largest airborne particles. Others choose to produce higher-efficiency pleated filters to allow for the capture of smaller particles that may cause health problems in building occupants.

Manufacturers also have choices when it comes to producing high-efficiency pleated filters. Some use filter media that relies solely on its mechanical structure to filter the air. This media is typically made of a cotton/poly blend. The other type of media uses both its mechanical structure and an added electret charge. This type of media is possible thanks to the benefits of synthetic, nonwoven fabric.

Bottom line: Filter media is no longer a commodity to be specified solely based on its purchase price. Indeed, filter purchasers are increasingly aware of issues associated with indoor air quality (IAQ) and energy efficiency. In their efforts to improve IAQ for building occupants and reduce the cost of HVAC energy consumption, they are realizing the added value and benefits of HVAC air filters made with synthetic, nonwoven filter media that can be produced to provide a combination of a robust mechanical structure and an electret charge.

ELECTRET TREATMENT ENHANCEMENT

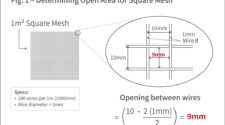

Particle capture in synthetic media can be enhanced by adding an electrostatic charge, creating an electro-mechanical structure that attracts particles with a natural charge (and those that pick up a natural charge as they pass through the air), similar to magnetic attraction.

There are several benefits of imparting an electret treatment to synthetic, nonwoven filter media that has a robust underlying mechanical structure:

A well-designed electret-treated media can be manufactured to provide high initial and high-sustained efficiency over the filter lifecycle. Filters that are designed to provide only mechanical efficiency begin their life at their lowest particle removal efficiency and rely on the building of the dust cake in the filter to increase efficiency.

The electrostatic effects created in an electret-charged media are particularly useful in increasing the capture efficiency for submicron particles. This is because, while submicron particles are much smaller than the void spaces present in most commercial electret media, the electrostatic forces within the media structure allow those particles to be removed with high efficiency. Mechanical-only media, on the other hand, must use extremely fine fibers or dense structures to achieve high efficiency with submicron particles, and this can create airflow resistance in the filter, which can lead to higher energy use/cost.

Studies have shown that filtration efficiency of electret-treated media is unaffected by relative humidity and by long-term warehousing at high temperatures (130┬░F), meaning the electret effect is resistant to age-related decay under conditions relative to its storage and use.

Electro-mechanical media typically delivers lower airflow resistance in the same filter construction as a mechanical-only filter. This translates into reductions in energy consumption and costs. Mechanical-only filters, on the other hand, tend to create significant drag or resistance, because their filtration mechanisms cause disruption of the particles in the air stream. The more resistance there is, the more energy is needed to push the air through the filter.

SELECTING FILTERS FOR IMPROVED IAQ

ASHRAE Standard 52.2 (Method of Testing General Ventilation Air-Cleaning Devices for Removal Efficiency by Particle Size) is used to test filters for efficiency and provides a useful tool for evaluating filtration effectiveness. The test measures the fractional particle size efficiency (PSE) of a filter, indicating its ability to remove particles of differing sizes between 0.3 and 10 microns in diameter. A MERV, or Minimum Efficiency Reporting Value, is assigned to the filter based on a minimum PSE. A MERV 1 is least efficient, while a MERV 16 is most efficient.

Keep in mind that, depending on the type of filter media used (mechanical-only or mechano-electret), two similar filters of the same MERV rating can have different filtration efficiencies. That is why, to conduct a more thorough filter selection review, it’s important to look beyond the MERV rating and request and review each filter’s complete ASHRAE 52.2 test report.

The full test report will provide the efficiency of the filter over three particle size ranges: E1 (very fine particles in the 0.3 to 1.0 micron range), E2 (fine particles in the 1.0 to 3.0 micron range), and E3 (coarse particles in the 3.0 to 10.0 micron range). The E1, E2 and E3 ASHRAE 52.2 test values for a given filter provide a more complete picture of the filter’s performance of the three particle size ranges. The 52.2 test also provides additional information such as airflow resistance, which can impact energy use during the filter’s life.

Many pleated filters today (especially at commonly used MERV 8) have very low E1 and E2 efficiencies. In fact, under the ASHRAE 52.2 Standard, there is no minimum requirement threshold for E1 particulate capture below a MERV 14 rating and no minimum requirement threshold for E2 particulate capture below a MERV 9 rating. Filters with mechano-electret media often provide better E1 and E2 performance than is required by MERV.

When evaluating filters, be careful not to confuse the filter’s MERV and E1, E2 and E3 efficiencies with the results of the Standard’s Appendix J (Optional Method of Conditioning a Filter Using Fine KCL Particles), which should be reported as “MERV-A.” This Appendix was created to address the interest of critics of ASHRAE 52.2, who were concerned that air filters featuring an electret charge performed at a high filtration efficiencies during initial testing while their filtration efficiencies could decline in actual use.

The MERV-A test subjects the filters to extreme loads of fine KCl (potassium chloride) particles ÔÇö many times what the filter would be exposed to over its real-world, installed, useful life. It does not represent actual use conditions at all, but instead represents a “worst-case” scenario that is likely to never happen. In addition, differences in environmental conditions and lab-to-lab variances have also been uncovered, leading to the conclusion that techniques, which “condition” the filters, are not repeatable. Moreover, these same conditioning techniques have been shown to decrease the filtration efficiency of certain mechanical-only filters as well. These are some of the reasons the electret masking step was not added to the 52.2 Standard as a mandatory part of the test but was included as an option only.

CONCLUSION

High E1 and E2 efficiencies support healthier IAQ, as these are the particles that can travel into the deepest parts of people’s lungs. That is why it is so important to consider filters with mechano-electret filter media and to look beyond a filter’s MERV at the Fine Particle Efficiency rating as a true measure of a filter’s performance.

Remember: electret treatments are an enhancement of an underlying mechanical structure. The combination of different electret treatment patterns/charge distributions and different mechanical structures means that all electro-mechanical filters are not created equally.

An electret-treated media filter with depth loading synthetic, nonwoven media and a gradient density structure, in which the media’s fibers are more loosely packed on the upstream side and more densely packed on the downstream side, will help to reduce airflow resistance, enhance dust loading and prevent face loading of the filter.