January/February 2014 | Volume 34, No. 1

A good filtration system is designed to extend waterbase coolant life by keeping it constantly clean at a tolerable level. Coolant life extension is good economics but it carries more responsibility in managing the fluid. During this extended life, coolant could be lost from the system through normal spillage, carryout on parts, or evaporation.

All or any of these affect the strategy for replenishing lost coolant known as make-up.

Effective make-up procedures are needed to maintain fluid levels but also to protect the coolant from unwanted chemical reactions. The steps are simple but often the awareness of their importance is lacking.

- Pre mix the concentrate with some water before adding it to the system.

- Use treated water such as DI or RO for the make-up.

- Add to the system where make-up is mixed before going to the point of work.

- Monitor concentration routinely.

Concentrate should be premixed with some water before it is introduced into the tank. The expectation that it will mix in the tank of dirty coolant if it is added as a concentrate will be disappointing. The free oil will not go into solution that quickly. Test this statement by adding some oil in a beaker of clean water and see that it takes some time. Also if the addition is on the top of a tank with floating tramp oil and debris, the concentrate will not make it to the solution. It will stay as a sludge or take on the characteristic of tramp oil.

2. USE TREATED WATER

As more water is added for make-up due to evaporation it carries in dissolved salts that stay in solution and grow in concentration. With continued evaporation and make-up over the extended life of the coolant, the salt content can grow to levels where they can cause an intolerable reduction of coolant performance. This is reflected in a drop in pH, parts staining, and formation of undesirable soaps and breakdown of the stability of the solution.

To protect against this, make-up water should be either de-ionized or sent through a reverse osmosis unit. The de-ionized or “RO” water will come into the system free of salts so the salt concentration will stabilize. Water softeners may not be the answer since they merely exchange one salt for another. De-ionizing and RO units are readily available in moderate capacities as complete modules. Minimizing losses wherever possible will reduce make-up water needs so a packaged water treatment unit should not be prohibitive in size and cost.

Usually RO or DI water is not used for the initial mix. It may cause foaming because the coolant is clean and the water is “hungry.” Only the makeup water should be treated.

3. ADD TO THE SYSTEM WHERE IT WILL BE MIXED

Make-up water and soluble oil should be added in the dirty compartment or in the “dirty” side of the system. The fresh addition is to be thoroughly mixed with the older solution before it is sent to the work. If it is not mixed into the main body of coolant, the operation may be subjected to a lean coolant to hurt the operation; or too rich of a coolant where excessive foaming will occur.

4. MONITOR THE CONCENTRATION

When the coolant is lost through evaporation, this means the water phase is lost at a higher rate than the soluble oil. Therefore, more water must be added to the system. Concentration of the oil and water mixture must be continually monitored so make-up dosages can be adjusted to maintain the desired ratio.

When coolant is lost mainly due to carry-out or spillage, the ratio of water to oil loss is the same but with evaporation still a factor in the losses, the concentration still should be monitored.

EQUIPMENT

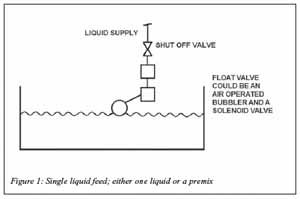

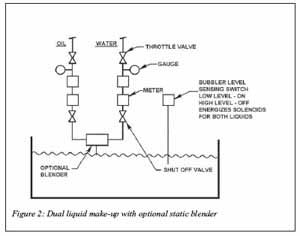

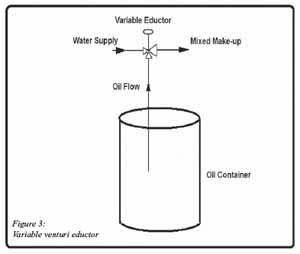

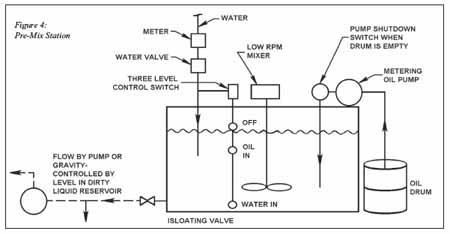

Figures 1, 2, 3, and 4 show simple schematics for typical make-up functions. Schematics (instead of photos) are offered since they reflect how the options work for a system.

Figure 1 shows a single float valve for one liquid. It can be for water only where oil is added independently, or a premix of both fluids.

Figure 2 reflects a dual liquid make-up unit, which can provide an automatic input of both liquids. It senses a “make-up on” level in the tank and adds a monitored amount of water and a related amount of oil. The bubbler level controller could also include two more levels for low and high level alarms.

Figure 3 indicates an adjustable venturi educator, which pulls a controlled amount of oil from the drum (tote) as water flows through the eductor. The venturi is adjustable so the amount of oil blended with the water can be changed.

A metering piston pump can be used in place of the eductor to accomplish the same objective. The pump is more expensive but can be justified for critical installations.

Figure 4 is a concept where there is a larger mixing station for multiple machines or a large central system. The module has a feed pump pulling oil from a drum or tote. Most mixing stations use a relatively large reservoir with a low RPM mixer to blend the solution. The level sensing switch would automatically monitor a ratio of water and oil. Once the fluid is mixed, the make-up flow can be initiated by an operator or by a level-control to feed the blend into the system. As shown the liquid can be pump-fed or flow by gravity.

MONITORING CONCENTRATION

There are two basic options to perform the routine monitoring of the concentration.

Remote tank side monitoring

- There are many hand-held measuring instruments, which can be used.

- Routine checks should be occasionally verified with follow-up laboratory checks by the plant or coolant supplier.

- Caution is advised to not let dissolved tramp oil mislead the readings. Tramp oil is not always free oil since some of it may go into solution and influence the reading.

LABORATORY CONCENTRATION ANALYSIS

Actual concentration analysis in the laboratory with standard practices will reveal accurate readings of the oil concentration and isolate the tramp oil factor.

For more information contact:

Joseph Marketing

120 Richmond Hill Court, Williamsburg, Virginia, 23185

Tel/Fax: 1-757-565-1549

Email: josephmarketing@verizon.net